Contact Sales at Sunceter.

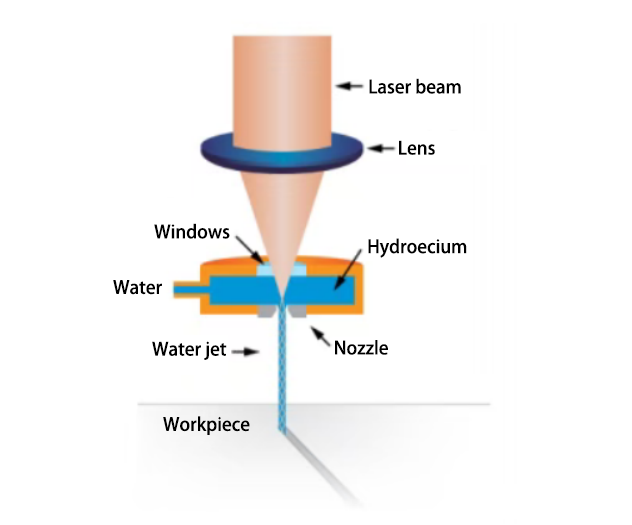

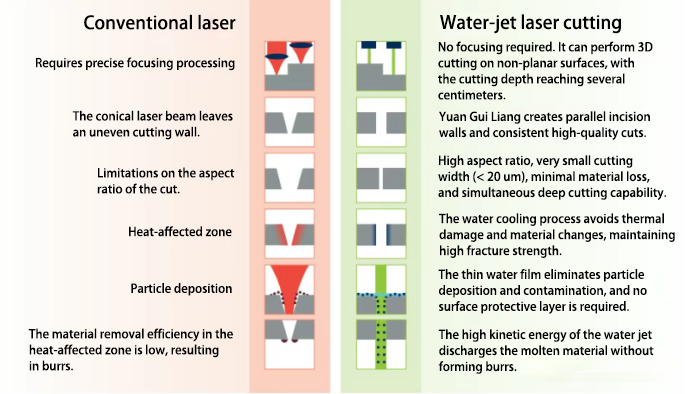

"Water-guided laser" possesses unique advantages that distinguish it from traditional laser processing. The water-guided laser precisely transmits the laser within the water jet through the total reflection effect of light at the "water-air" interface, in a manner similar to that of traditional optical fibers. The water jet can continuously cool the cutting area and effectively remove debris.

As a "cold, clean and controllable laser", The water-jet laser has solved the problems of thermal damage, tapering and lack of precision in dry laser cutting, It can provide high-quality laser processing results.

Suncenter new product:The "core strength" of the ultra-high pressure water circulation system

As a long-time practitioner in the field of high-pressure fluid control, Suncenter based on the processing characteristics of water-cooled lasers, Create a water-guided laser constant-pressure water supply system that combines "high pressure, constant pressure, purity, and intelligence". Its core advantage directly addresses the pain points of the industry:

1. Ultra-high pressure + low fluctuations, solidifying the "stable line" for laser transmission

Wide pressure coverage: The maximum working pressure can reach up to 60 MPa, meeting the requirements of all scenarios ranging from semiconductor micro-holes (low-pressure precision processing) to aerospace alloy deep holes (high-pressure efficient processing).

Constant pressure with high accuracy: Utilizing a segmented water pressure regulation technology (based on a utility model patent design), combined with real-time closed-loop control by PLC. The water pressure fluctuation can be stabilized within ±0.1 MPa. Much better than the industry average;

Flexible pressure switching: Supports rapid switching among multiple gradient water pressure ranges without the need for manual adjustment. It can meet the processing parameter requirements of different materials (such as tungsten steel, polycrystalline diamond), reducing the debugging time.

2. Ultra-pure water circulation, safeguarding the "cleanliness" of the optical path

Deep purification system: Integrates multiple-stage filtration and ion exchange modules, with water resistivity reaching 18.2 MΩ·cm. It thoroughly removes impurities and metal ions, avoiding nozzle wear and laser scattering. Closed-loop cycle design: The utilization rate of water resources has been increased to over 95%, reducing wastewater discharge, which not only lowers production costs but also complies with environmental protection requirements. Real-time water quality monitoring: Equipped with online water quality sensors, it will immediately give an alarm if the water quality exceeds the standard, ensuring that the processing process is clear and the energy is stable throughout.

3. Intelligent adaptation + high reliability, enabling the production line to "operate efficiently"

Compatible with multiple devices: The modular design enables it to be compatible with mainstream water-guide laser equipment such as Zhongke Yuchen RJ305 and Swiss Synova, and it can be easily integrated into the production line without significant modifications.

Intelligent Operation and Maintenance: Equipped with a 7-inch touch screen, it can display real-time data on pressure, flow, and water quality, supports self-diagnosis of faults and remote monitoring, reducing the need for manual intervention.

Long-life design: The flow components are made of 316L stainless steel and other corrosion-resistant and wear-resistant materials. The segmented pressure regulation reduces the pressure difference of the pressure reducing valve, and the lifespan of the core components is increased by more than 30%.

Empowering High-End Manufacturing: The "Reliable Partner" from Laboratory to Production Line

As a pioneer in the field of high-pressure fluid control, Suncenter has developed a water-guided laser constant pressure water supply system based on the processing characteristics of water-guided lasers. This system features "high pressure, constant pressure, purity, and intelligence", and its core advantages directly address the industry's pain points:

1. In the aerospace field: Adapted for the processing of air film holes in DD6 alloy turbine blades. The water pressure stability ensures that the roundness error of the inlet of the inclined hole (45°) is less than 20 μm, and there is no recast layer, meeting the requirements for high-temperature strength.

2. In the semiconductor field: The ultra-pure water circulation ensures the processing of micro-pores smaller than 10 μm, with no laser energy scattering and the aperture accuracy deviation controlled within ±1 μm.

3. In the medical field: Low fluctuation water pressure supports the precise cutting of titanium alloy implants, without causing thermal damage, ensuring biocompatibility and reducing the subsequent polishing process.

This new product from Suncenter, filled the gap in the high-end water-guided laser water supply system —— From core components to complete line solutions, China's high-end manufacturing is forming a "self-controlled" closed loop.

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist