Compressed Air Driven Gas Booster Pump- DGD series

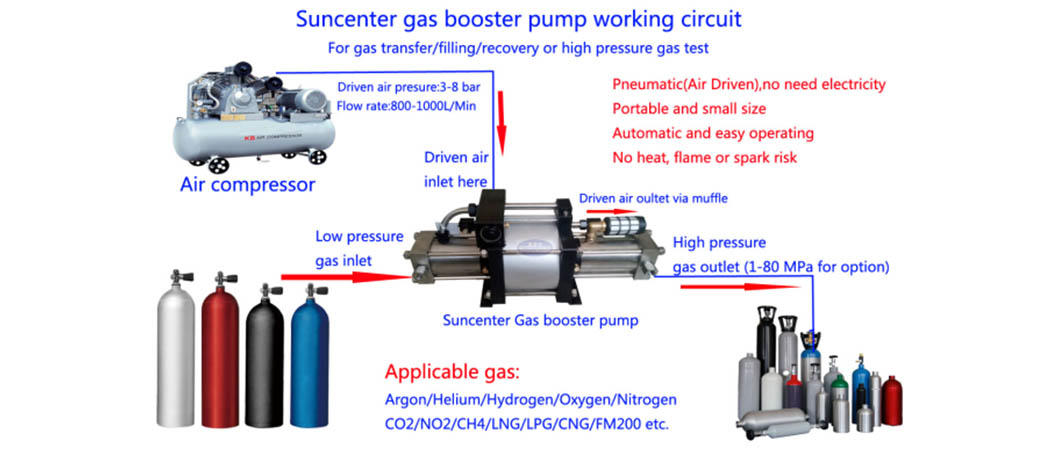

Suncenter Air Driven Gas Boosters provide for pressures up to 80Mpa (11,600 psi). Used for virtually all known gases, these boosters are ideal for increasing gas pressure, transferring high pressure gas, charging cylinders and scavenging. Key features include:

Applications for Air Driven Gas Boosters

SUNCENTER Air Driven Gas Boosters provide for pressures up to 80Mpa. Used for oil free compression not only of air or Nitrogen, but also flammable and risk gases like hydrogen, oxygen and natural gas. These boosters are ideal for increasing gas pressure, transferring high pressure gas, charging cylinders and scavenging.

Air driven boosters are an efficient alternative instead of electrically driven products and can be used in explosion- proof areas.

As a result of the wide range of models it is possible to select the optimum booster for each application. Single stage, double acting or two stage boosters or a combination of these models can be used to achieve different operating pressures and flow capacities.

SUNCENTER Air Driven Gas Boosters are ideal and widely used for hydrostatic and burst testing for valves, pipes, tubing and pressure vessels; Calibration for safety valves; Automobile regulator detecting and telecommunication cable inflatable appliances.

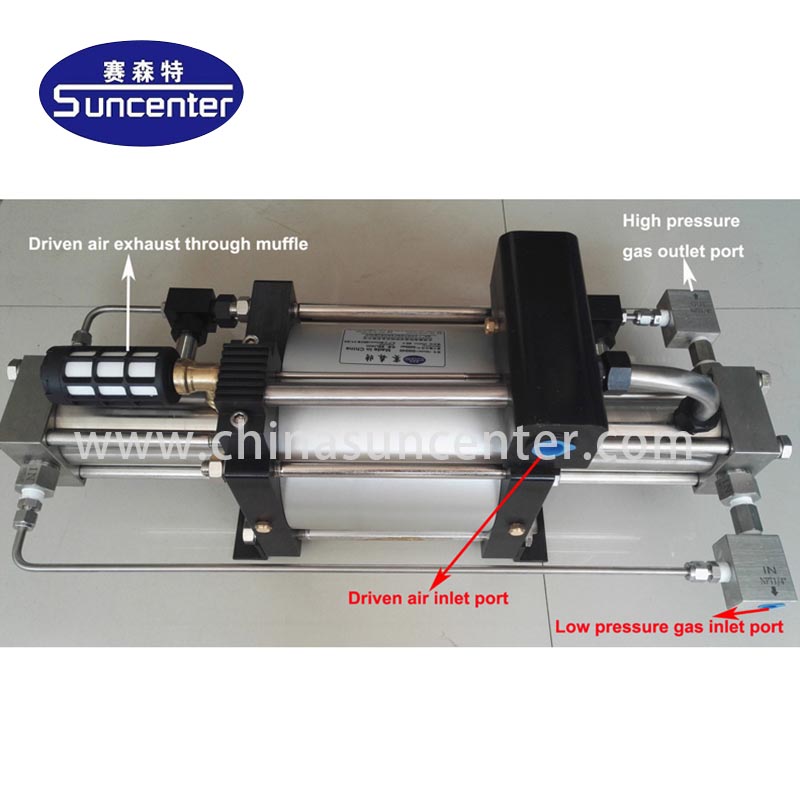

DGD series gas booster pumps(Double acting ):

◪ DGD series pumps are double acting, with single air driven heads type.

◪ DGD pumps are available with high quality seals, which provide significantly better service life

◪ Double pump heads with exhaust cooling devices.

◪ All components in contact with the gas are made of stainless steel.

◪ Pipes mounting way are available as customized.

Model | Pressure boost ratio | Min. gas Inlet pressure PA (bar) | Max.gas Inlet pressure PA (bar) | Max. gas outlet pressure PB (bar) | Driven air pressure PL | Formula to | Connection: | Max. flow at driven air pressure of 6bar (L/min) |

DGD10 | 10:1 | 3.5 | 80 | 80 | 2bar-8 bar | 10XPL+ PA | 3/8/3/8 | 410(at PA of 6 bar ) |

DGD15 | 15:1 | 5 | 120 | 120 | 2bar-8 bar | 15XPL+ PA | 3/8/3/8 | 350 (at PA of 6 bar ) |

DGD25 | 25:1 | 10 | 200 | 200 | 2bar-8 bar | 25XPL+ PA | 1/4/1/4 | 396(at PA of 20 bar ) |

DGD40 | 40:1 | 15 | 320 | 320 | 2bar-8 bar | 40XPL+ PA | 1/4/1/4 | 320(at PA of 40 bar ) |

DGD60 | 60:1 | 25 | 480 | 480 | 2bar-8 bar | 60XPL+ PA | 1/4/1/4 | 215(at PA of 40 bar ) |

DGD100 | 100:1 | 35 | 800 | 800 | 2bar-8 bar | 100XPL+ PA | 1/4/M14*1.5 | 300(at PA of 60 bar ) |

DGD130 | 130:1 | 50 | 1040 | 1040 | 2bar-8 bar | 130XPL+ PA | 1/4/M14*1.5 | 180(at PA of 60 bar ) |

2DGD series gas booster pumps(Double acting, double air driven heads ):

◪ DGD series nitrogen booster pump

Model | Pressure boost ratio | Min. gas | Max.gas Inlet pressure PA (bar) | Max. gas | Driven air pressure PL | Formula to | Connection: | Max. flow at driven air pressure of 6bar (L/min) |

2DGD10 | 10:1 | 3 | 80 | 80 | 2bar-8 bar | 10XPL+ PA | 1/2 / 1/2 | 980(at PA of 6 bar ) |

2DGD25 | 25:1 | 6 | 200 | 200 | 2bar-8 bar | 25XPL+ PA | 3/8 / 3/8 | 560(at PA of 10 bar ) |

2DGD40 | 40:1 | 25 | 320 | 320 | 2bar-8 bar | 40XPL+ PA | 3/8 / 3/8 | 480(at PA of 40 bar ) |

2DGD60 | 60:1 | 30 | 480 | 480 | 2bar-8 bar | 60XPL+ PA | 3/8 / 3/8 | 320(at PA of 40 bar ) |

Suncenter DGS Series Pneumatic (Air driven) Gas Booster Pump System

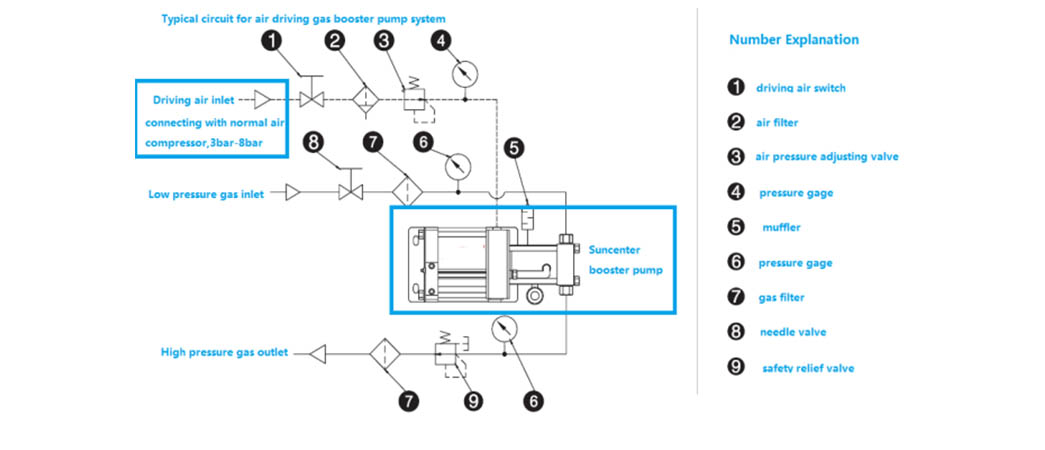

DGS gas booster system = gas booster pump+ following valves, gauges, and parts

Suncenter - Pneumatic gas booster system are compact and delicacy solution tailored to customer specific requirements with gas boosters as well as all accessories to be fitted and installed in the frame or a closed cabinet.

To operate this system, the pressure gauges, valves and pressure regulators have to be fitted on panels. The outlet pressure is easily to be set through a simple air regulator.

The pump stops automatically when this end pressure is reached and restarts with a slight drop in the outlet pressure or an increase in the air drive pressure.

Suncenter - Pneumatic booster system are used for oil free compression of clean shop air as well as industrial gases like Argon, Helium, Oxygen, Hydrogen and Nitrogen,CO2, etc..Driven air from 3 bar to 8 bar (from air compressor).

Operating pressure up to 80 MPa, for higher pressure, pump with double driven heads is an ideal option.

The hottest selling- model A and model C cabinet picture

◪ The standard gas booster pumps system including following parts:

◪ Air –driven gas booster pump (DGA/DGD/DGT three series for choosing)

◪ Stainless steel (carbon steel) material cabinet (Three models for choosing)

◪ F.R.L combination for driven air (adjusts air pressure, add lubricating oil and water filter)

◪ Driven air switch (Pump starting switch), driven air pressure gauge

◪ Gas inlet switch, Gas inlet pressure gauge

◪ Gas outlet switch, Gas outlet pressure gauge, unloading valve, interconnecting pipes etc.

◪ And we could also customize it according to clients’ special requirement.

◪ DGD series gas booster working picture

◪ DGS-DGD series gas booster system for nitrogen gas spring charging

◪ Suncenter portable nitrogen spring filling machine is widely used in the production process of high pressure nitrogen gas spring. It is used to inject high nitrogen pressure into the high pressure chamber of nitrogen gas spring. High pressure nitrogen gas spring is often used in relatively accurate automobile molds. The pressure can reach several tons, the volume is small, clean and easy to use. It can also be used for nitrogen spring pressure supplementation. This portable nitrogen spring inflator has the advantages of small size, high pressure and convenient carrying.

features

※ Compressed Air driven - no electricity required (connect to normal air compressor)

※ In order to extend the lifetime of the pump, the driving air pressure should not be higher than 8 bar

※ No airline lubricator required

※ Hydrocarbon free - separation between air and gas sections

※ Pressures to 80Mpa (11,600 psi)

※ Wide range of models with different ratios

※ Built-in-cooling on most models

※ Easy to install, operate and maintain

※ Best price / performance ratio

※ No heat, flame or spark risk and explosion proof

※ Automatic pressure holding, whatever the cause of the pressure drop, the Suncenter pump will automatically start, keep the loop pressure constant

※ Applicable gas:Air/Ar(Argon)/He(Helium)/H2(Hydrogen)/O2(Oxygen)N2(Nitrogen) CO2/NO2/CH4/C2H2/LNG/LPG/CNG/FM200/SF6/H2S etc

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist