Electric-powered Hydraulic Tube Expander

This Electric powered hydraulic tube expander is a special equipment used to expansion jointing tubes and tube sheet in the manufacture of boilers, heat exchangers, condensers, high pressure heaters and other equipment. The equipment can reliably expand heat exchange tubes of various specifications and materials, and is especially suitable for the expansion of thick tube sheets and large-diameter tube heat exchangers.

Working Principle

This equipment adopts hydraulic expansion joint method. The electric motor in the hydraulic power pack drives the hydraulic pump to pressurize the water or hydraulic oil, then the high-pressure hydraulic pressure is delivered to the expanding-handle, and finally reaches the expanding-rob. The expanding-rob is expanded under the drive of high hydraulic pressure to complete expansion-joint.

Features

Hydraulic expansion joint, there is no oil pollution at the expansion joint, and the welding after expansion is not affected

Automatic water replenishment, automatic cooling

PLC control, the outlet pressure can be set accurately

Maximum outlet pressure up to 350Mpa

Pressure-holding function, the pressure-holding time can be selected arbitrarily from 0.1 to 50 seconds

Electrical protection device built-in

Expanding-handle weight is 0.8Kg only, easy to operate

It can work continuously, one person can continuously expand and connect, and can expand 6-8 tubes per minute

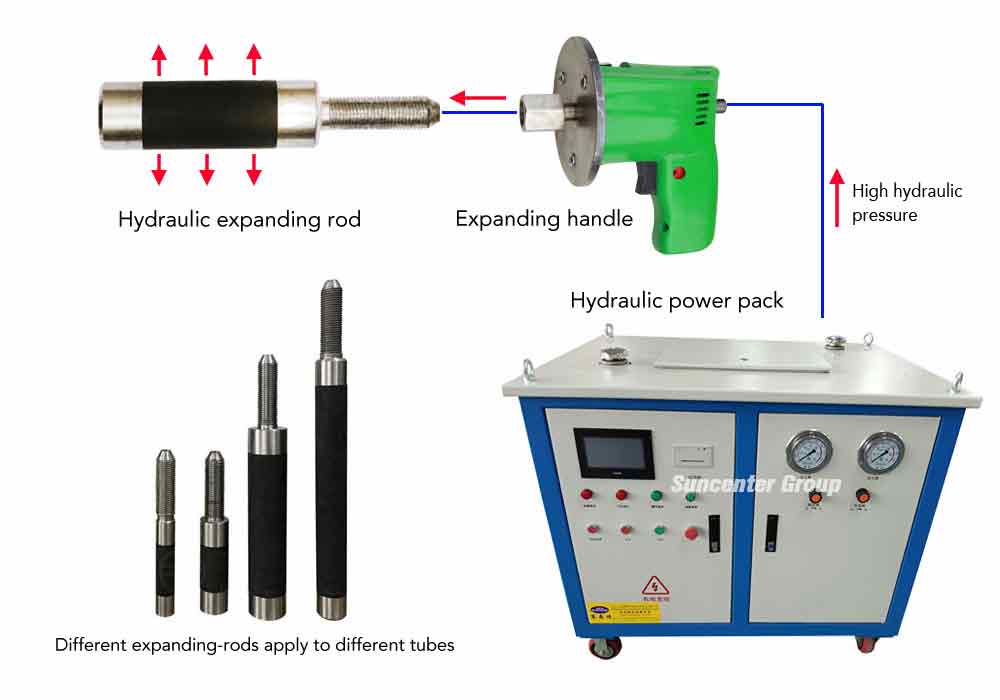

Composition

The Hydraulic tube expander is composed of hydraulic control system, pressure amplification system and hydraulic expansion-joint control system.

Components

The Hydraulic tube expanding machine includes three main components:

Hydraulic power pack: generate and output high hydraulic pressure

Expanding-handle

Hydraulic expanding-rod:

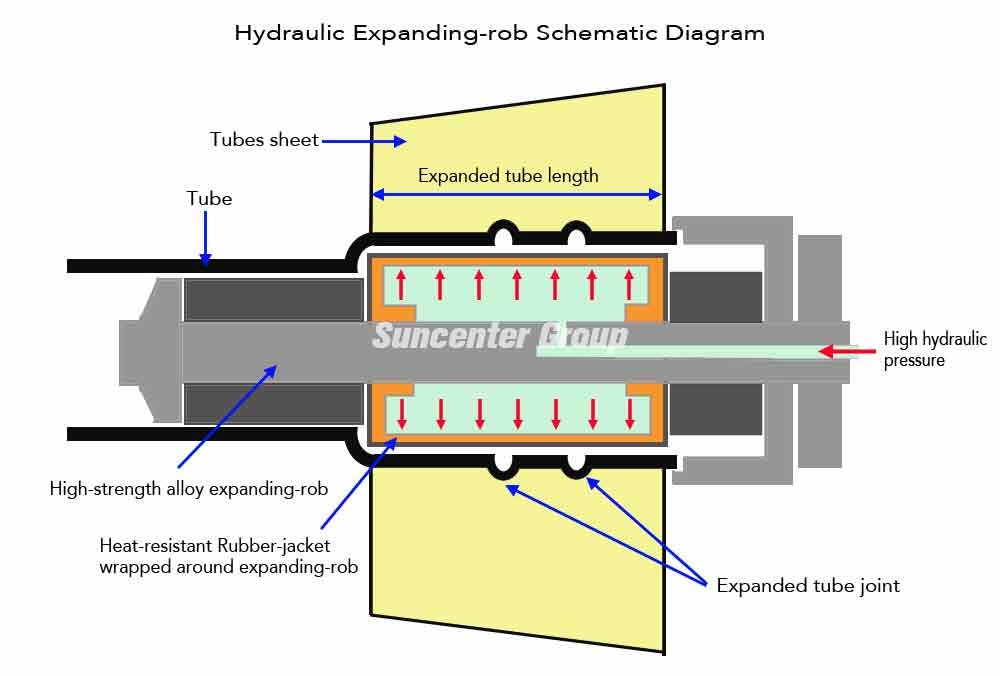

The one-piece hydraulic expanding-rod is composed of high-strength alloy steel core rod and high-pressure resistant elastic rubber. The integrated design can withstand ultra-high pressure without using seals. It is easy to use and has high work efficiency. It uses the radial pressure generated by the high-pressure hydraulic pressure input from the hydraulic power pack to the elastic rubber body to expand tubes on the tube sheet, so that the pipe material undergoes plastic deformation, so as to realize the expansion joint between tubes and the tube sheet.

| Maximum outlet pressure | 350Mpa | Expanding handle weight | 0.8Kg |

| Tube's outer diameter | ≥5mm | Hydraulic power pack dimension | 126x96x150cm |

| Tube sheet's thickness | ≥6mm | Hydraulic power pack weight | 450Kg |

| shell of tube | 0.2 - 18 mm | Motor power | 5.5KW |

| Expansion length | 6 - 4600 mm | Total power | 6.5KW |

| Connector of expanding-rob | M10X1 (mm) | Hydraulic pump flow rate | 10L/min |

| Tube sheet holes roughness | 6.3μm | Liquid tank | 100L |

| Expansion-joint medium | water or oil | Electric power | 380V |

| Expansion-joint efficiency | 5-8 tubes/minute | Control mode | PLC with touch screen |

Operation Instructions

1. Turn on “Power” button.

2. Set pressure value in touch screen.

3. Evacuate the air in the high-pressure hose and the expanding-rod:

4. The operation method of the expanding- rod: insert expanding-rod into tube until the expansion position, press the switch on the expanding-handle and then release it. At this time, the "boost" indicator light is on, and the machine starts to automatically control the expansion process; When the pressure reaches your preset pressure value, the boosting stops, and it automatically enters the depressurizing state. At this time, the "depressurization" indicator lights up; after the depressurization is completed, the expansion rod can be pulled out. Then expand the next tube, and so on.

Workplace Real Shot

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist