Air Driven Liquid CO2 Booster Pump-DGG/DGGD Series.

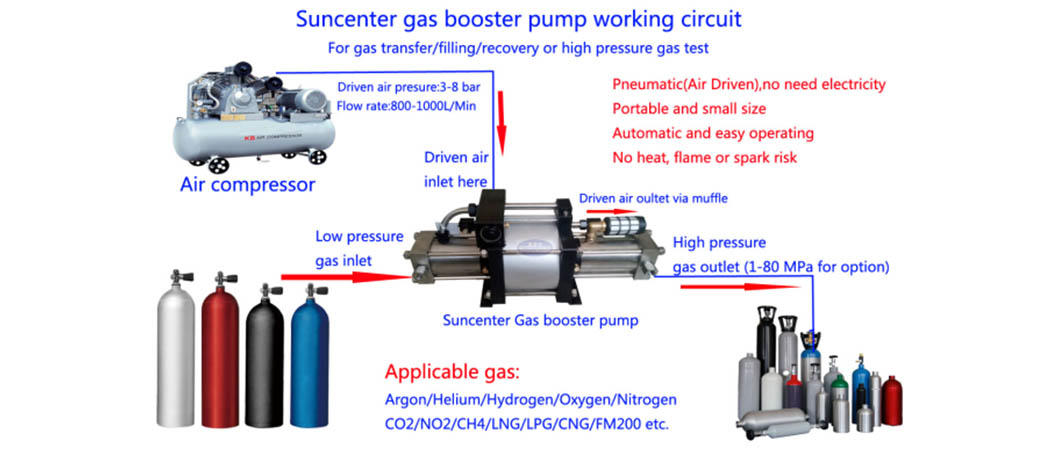

SUNCENTER pumps are air driven at a drive air pressure of 2bar to 8bar by the normal air compressor. Basically the principle of operation is similar to a reciprocating amplifier where control of the piston at the end position is regulated by a pilot operated 4/2 way valve.

Suncenter pumps feature a large air piston joint to a smaller diameter plunger. The pressure ratio is the difference of these two areas and is the method of determining maximum outlet pressure. Higher pressures obtained by using higher pressure ratios.Suncenter model numbers reflect the pumps nominal pressure ratios, while the technical data indicates exact ratios. The outlet pressure is easily to set through a simple air regulator. By multiplying the pressure ratio by the available shop air pressure, the nominal outlet pressure can be calculated.

DGG Series Liquid CO2 Booster Pumps(Single acting)

◪ DGG Series Liquid CO2 Booster Pumps(Single acting)

Model | Pressure Boost Ratio | Driven air pressure PL | Formula to calculate outlet pressure | MAX Outlet | Liquid inlet Connection | Liquid outlet Connection | MAX Flow (L/min) |

DGG6 | 6:1 | 2-8 bar | 48 | NPT1/2 | NPT1/2 | 29.91 | |

DGG10 | 10:1 | 2-8 bar | 10XPL | 80 | NPT1/2 | NPT1/2 | 18.84 |

DGG16 | 16:1 | 2-8 bar | 16XPL | 128 | NPT1/2 | NPT1/2 | 12.42 |

DGG28 | 28:1 | 2-8 bar | 28XPL | 224 | NPT1/2 | NPT1/2 | 7.11 |

DGG40 | 40:1 | 2-8 bar | 40XPL | 320 | NPT1/2 | NPT1/2 | 4.89 |

DGG64 | 64:1 | 2-8 bar | 64XPL | 512 | NPT1/2 | NPT3/8 | 3.08 |

DGG80 | 80:1 | 2-8 bar | 80XPL | 640 | NPT1/2 | NPT3/8 | 2.44 |

DGG100 | 100:1 | 2-8 bar | 100XPL | 800 | NPT1/2 | NPT3/8 | 1.92 |

DGG130 | 130:1 | 2-8 bar | 130XPL | 1040 | NPT1/2 | M14X1.5 | 1.47 |

DGG175 | 175:1 | 2-8 bar | 175XPL | 1400 | NPT3/8 | M14X1.5 | 1.14 |

DGGD Series Liquid CO2 Pumps(Double acting)

◪ DGGD Series Liquid CO2 Pumps(Double acting)

Model | Pressure Boost Ratio | Driven air pressure PL | Formula to calculate outlet pressure | MAX Outlet | Liquid inlet Connection | Liquid outlet Connection | MAX Flow (L/min)** |

DGGD4 | 4:1 | 2-8 bar | 4XPL | 32 | NPT1/2 | NPT1/2 | 70.00 |

DGGD6 | 6:1 | 2-8 bar | 6XPL | 48 | NPT1/2 | NPT1/2 | 48.60 |

DGGD10 | 10:1 | 2-8 bar | 10XPL | 80 | NPT1/2 | NPT1/2 | 30.61 |

DGGD16 | 16:1 | 2-8 bar | 16XPL | 128 | NPT1/2 | NPT1/2 | 19.73 |

DGGD28 | 28:1 | 2-8 bar | 28XPL | 224 | NPT1/2 | NPT1/2 | 11.30 |

DGGD40 | 40:1 | 2-8 bar | 40XPL | 320 | NPT1/2 | NPT3/8 | 7.69 |

DGGD64 | 64:1 | 2-8 bar | 64XPL | 512 | NPT1/2 | NPT3/8 | 4.94 |

DGGD80 | 80:1 | 2-8 bar | 80XPL | 640 | NPT1/2 | NPT3/8 | 3.96 |

DGGD100 | 100:1 | 2-8 bar | 100XPL | 800 | NPT1/2 | NPT3/8 | 3.13 |

DGGD130 | 130:1 | 2-8 bar | 130XPL | 1040 | NPT1/2 | M14*1.5 | 2.40 |

DGGD175 | 175:1 | 2-8 bar | 175XPL | 1400 | NPT3/8 | M14*1.5 | 1.81 |

◪ Liquid carbon dioxide booster pump and pressurization equipment, commonly used in carbon dioxide supercritical extraction of various plant extracts, material foaming, and carbon dioxide fire extinguisher filling. Among them, carbon dioxide extraction is often used in biopharmaceuticals. Experimental research works by using a special pump for liquid carbon dioxide to pressurize carbon dioxide to a supercritical state, which is used to decompose various elements in plants for easy extraction.

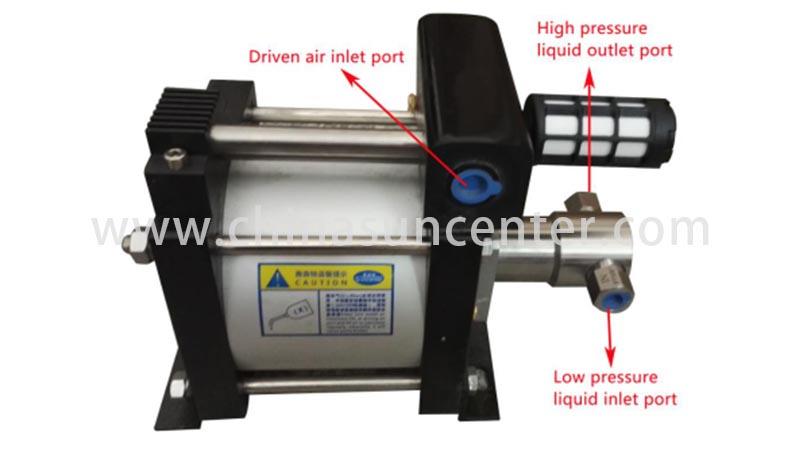

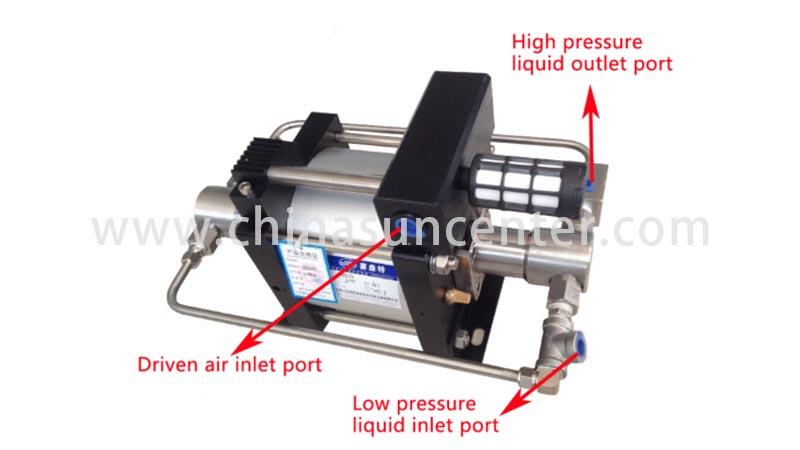

DGGD series liquid CO2 pump working picture

◪ DGGD series liquid CO2 pump working picture

features

※ Compressed Air driven - no electricity required (connect to normal air compressor)

※ In order to extend the lifetime of the pump, the driving air pressure should not be higher than 8 bar

※ No airline lubricator required

※ Wide range of models with different ratios

※ Built-in-cooling on most models

※ Easy to install, operate and maintain

※ Best price / performance ratio

※ No heat, flame or spark risk and explosion proof

※ Automatic pressure holding, whatever the cause of the pressure drop, the Suncenter pump will automatically start, keep the loop pressure constant

※ Applicable for liquid CO2/liquid+gas mixed CO2/Supercritical CO2

※ For liquid CO2 cylinder transfer/filling

※ For CO2 Fire Extinguisher filling

※ For Supercritical CO2 extraction

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist