Hydraulic/hydrostatic/burst pressure test machine – Computer control with armored glass protection cabinet

Suncenter has rich experience in the hose/tube/pipe/valve/sensor/cylinder/guage pressure test field, we can provide reliable performance hydraulic pressure test equipment, leakage test equipment, burst test equipment and impulse test equipment, according to the standard of (GB/T5568, GB7939, ISO6802, ISO6803, ISO8032, GB/T12722, gb16897, GB/T5563, GB/T10544 etc.)do the test to the hydraulic hose and hydraulic hose assembly, automobile brake pipe, power train pipes and other pressure parts for pressure performance test.

Product application scope and functional characteristics:

Applicable range of hydraulic pressure test equipment:

Automobile steering tube, brake pipe, air-conditioning pipe, oil pipe, water pipe cooling, radiator, heater hose, hydraulic equipment, condenser, evaporator, air conditioning filter hose, turbocharging system hose, car brake pump, a cylinder body, a project hydraulic hose, air hose and manifold, rigid pipe, joints, valves,cylinder, pressure gauges, pressure sensor,pressure vessel, pressure transmitter etc.

The main components is the mature products produced by our company

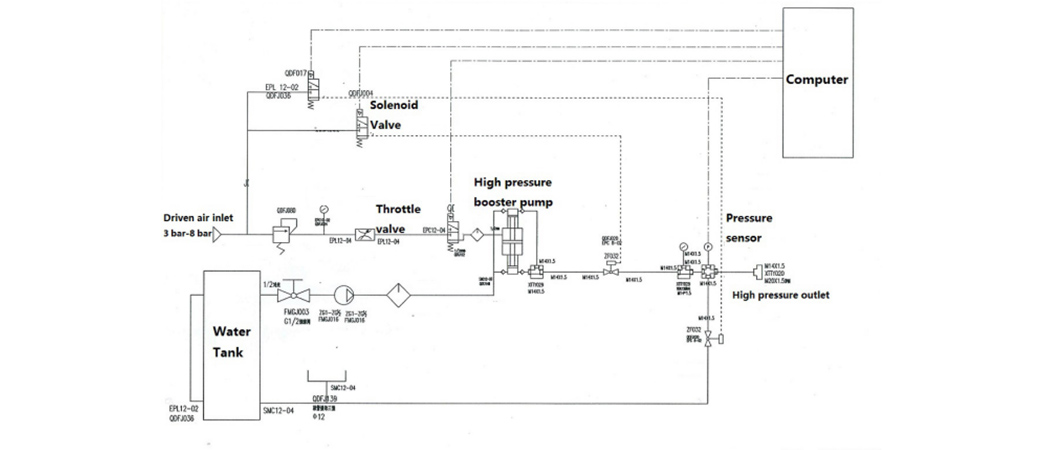

The piping system with non welded connection.The test fluid system and driving fluid system are separated; it is more convenient for test temperature control and test media diversification

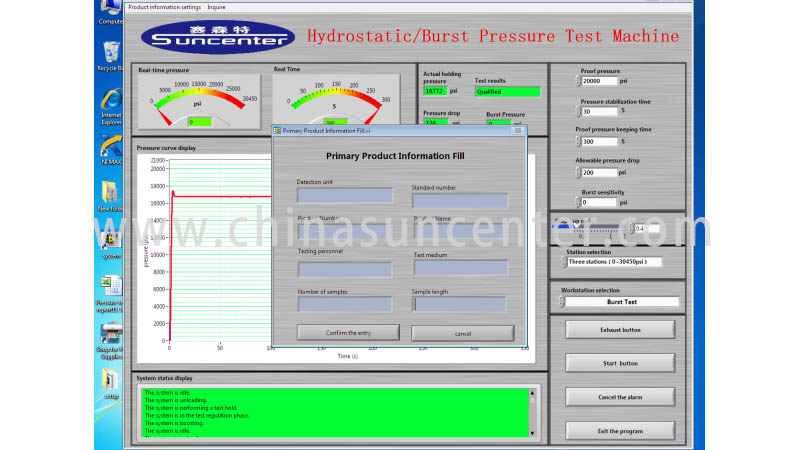

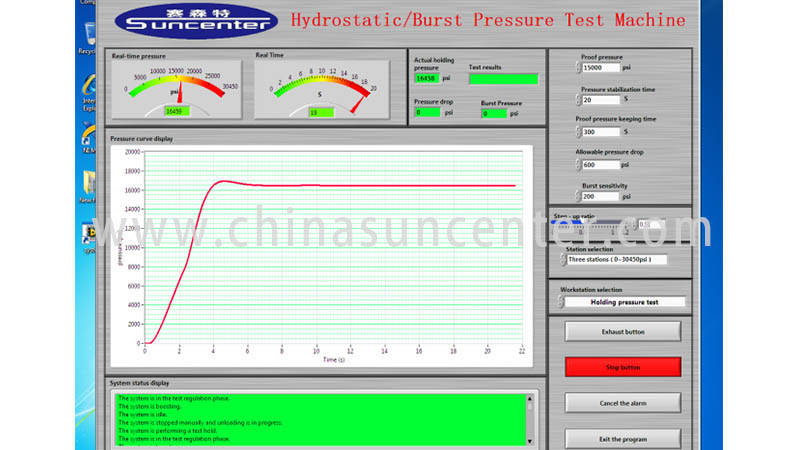

The software adopts force control configuration software or written in LABVIEW (computer control)

A variety of ancillary tooling, meet different specimens of installation

In the testing process, the pressure can be automatically compensated; time after the bursting pressure decreased rapidly, pressure automatic stop system;The protection of tooling, special design, can effectively protect the damage of blasting operation personnel and equipment.

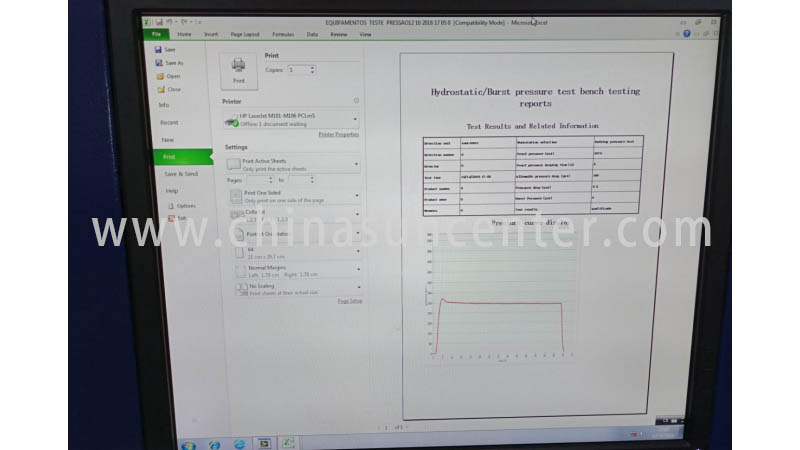

The realization computer control function, can be free to set up a water filled exhaust time, holding pressure time, aeration cleaning time, test pressure in the process of the experiment can be set arbitrarily single or multi section pressure maintaining test, can also holding pressure directly after blasting, boost the speed to maintain a constant, can realize stepless adjustment and test data and curve parameters can real-time display, can automatically save the test results, and any print test reports. (computer control)

System technical parameters and composition

Model: SHT-GD175-CC

SHT------- Suncenter Hydraulic Pressure Test Machine

GD175-------Suncenter DGGD175 model hydraulic booster pump

CC------- Computer control

Drive source: clean compressed air

Driven by compressed air pressure: 3-8bar (recommended driving pressure of ≤8bar)

The maximum air consumption: 600LN/min

The maximum output pressure: 1400 bar.

Working principle

Model | Pressure Ratio | MAX Outlet | Driven Air inlet port | High pressure Outlet port | MAX Flow |

SHT-GD4-CC | 4:1 | 32 | G 1/2 | NPT/ZG | 70.0 |

SHT-GD6-CC | 6:1 | 48 | G 1/2 | NPT/ZG | 48.60 |

SHT -GD10-CC | 10:1 | 80 | G 1/2 | NPT/ZG | 30.61 |

SHT-GD16-CC | 16:1 | 128 | G 1/2 | NPT/ZG | 19.73 |

SHT-GD28-CC | 28:1 | 224 | G 1/2 | NPT/ZG | 11.30 |

SHT-GD40-CC | 40:1 | 320 | G 1/2 | NPT/ZG | 7.69 |

SHT-GD64-CC | 64:1 | 512 | G 1/2 | NPT/ZG | 4.94 |

SHT-GD80-CC | 80:1 | 640 | G 1/2 | NPT/ZG | 3.96 |

SHT-GD100-CC | 100:1 | 800 | G 1/2 | NPT/ZG | 3.13 |

SHT-GD130-CC | 130:1 | 1040 | G 1/2 | NPT/ZG | 2.4 |

SHT-GD175-CC | 175:1 | 1400 | G 1/2 | NPT/ZG | 1.81 |

SHT-GD255-CC | 255:1 | 2040 | G 1/2 | NPT/ZG | 1.23 |

SHT-GD400-CC | 400:1 | 3200 | G 1/2 | NPT/ZG | 0.79 |

SHT-G510-CC | 510:1 | 4080 | G 1/2 | NPT/ZG | 0.65 |

SHT-G800-CC | 800:1 | 6400 | G 1/2 | NPT/ZG | 0.42 |

◪ Burst hydrostatic pressure test machine for hose/pipes

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist