Impulse pressure test machine – Computer control with armored glass protection cabinet

This test equipment is mainly used in the pulse test. As the main equipment of the fatigue life under the pulse pressure, the test stand has an important effect on ensuring the quality and improving the reliability. Test pressure, test times, etc.. Can deal with abnormal situation automatically, after the test can print test report.

The whole control system, we use computer + board analog control system + sensor switch control mode, and close monitoring of all of the switch, and the servo logic, ensure the system safety and reliability, capable of fault record, automatic lock logic system, ensures the test safety unattended.

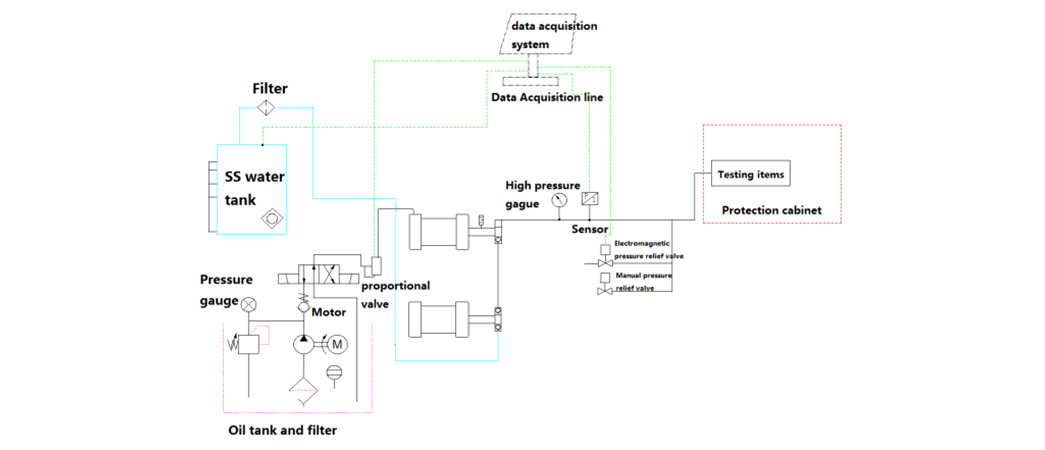

The equipment is mainly divided into hydraulic power system, computer control system, pulse executive system and data acquisition system.

Equipment characteristics

◪ Test medium: water/hydraulic oil

◪ Test pressure: 0~600Mpa (adjustable)

◪ Pulse frequency: 1 - 60/min (adjustable),

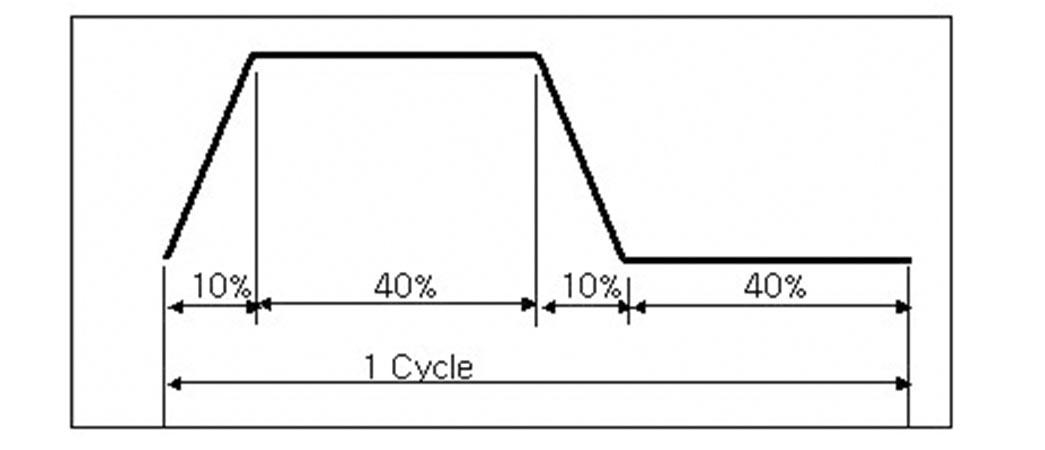

◪ Pulse pressure waveform: basic square wave (square, trapezoidal wave), pulse width adjustment can be carried out in accordance with the requirements of your unit.

◪ Test medium temperature: Room temperature to 120 degrees centigrade

◪ Test times 150 thousand times (according to customer requirements)

◪ Pressure output port: can be equipped with standard connection test interface

◪ Advanced technology, reasonable structure design. Beautiful appearance features.

◪ All pressure parts are internationally renowned standard parts, without any welding connection, convenient disassembly, high safety factor, long life, easy maintenance.

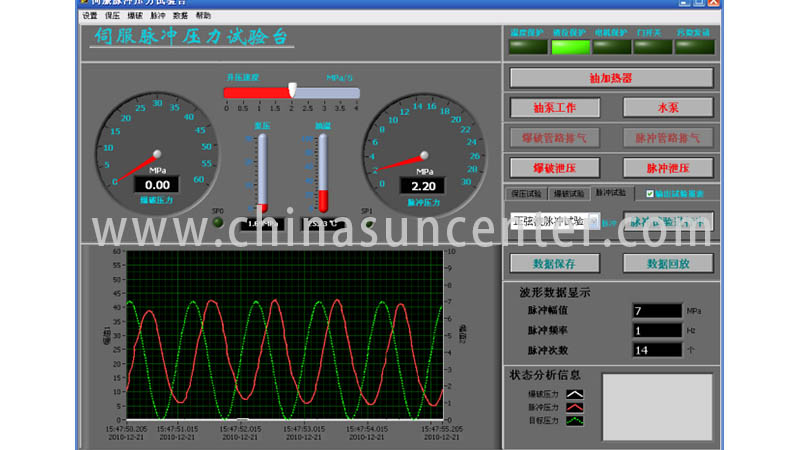

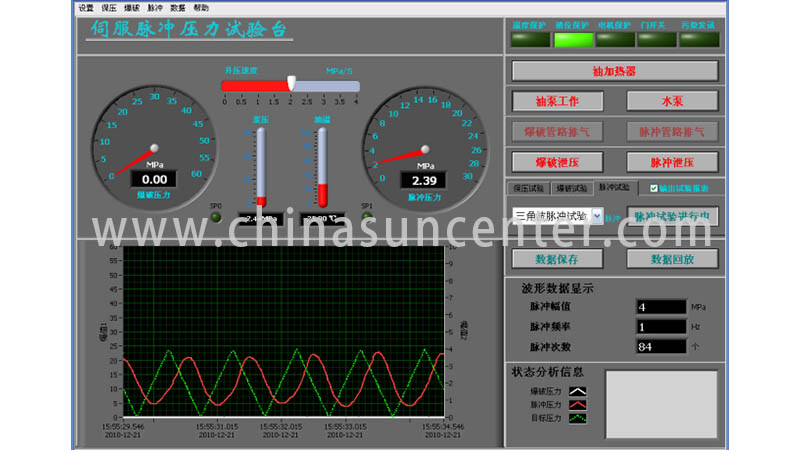

◪ The computer can control the rate of increase in real time to display the pressure curve, the test can be printed after the test report.

◪ The use of servo control technology, can accurately control the pressure

◪ Can carry out a variety of abnormal conditions, including pressure, power supply and other abnormal conditions.

◪ The equipment pulse pump piston pulse mode, the specific action is divided into one step (boost) and step two (relief valve) process;

◪ Computer data acquisition and processing, can print test pressure curve and set test parameters and other test items.

◪ The test can freely set the number of cycles, when the requirements can automatically stop the test;

◪ Support the automatic data storage;

◪ The experimental data can be returned, can be in accordance with the experimental time, the number of experiments and other experimental results.

Impulse principle diagram

Impulse test machine-Control software

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist