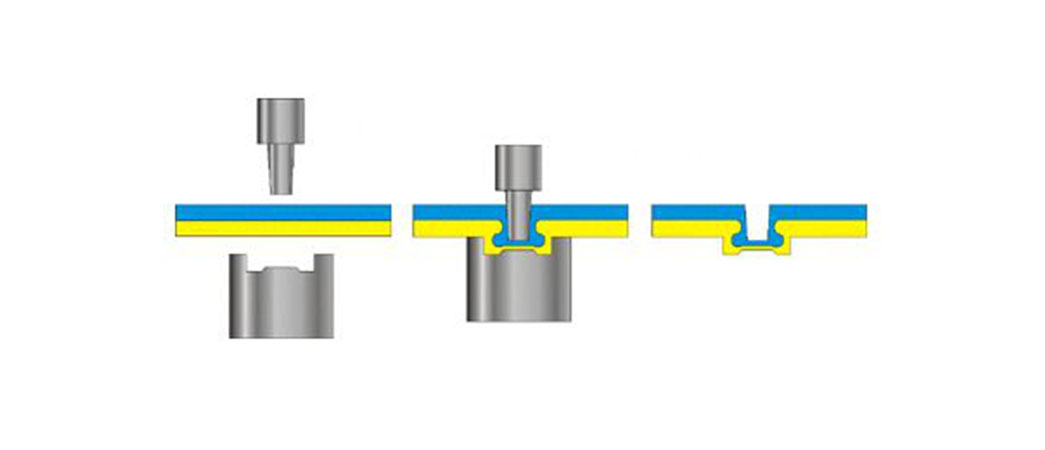

SSTPR04/SSTPR08 Model Rivetless riveting machine

◪ Technical parameter:

◪ Impact pressure 4.0T/8.0T

◪ The power source:Hydro pneumatic

◪ Voltage: 50Hz 220V

◪ Total travel: 100mm

◪ Compressed air source need:3bar-8 bar

◪ Weight: 700KG

◪ Max thick of board 2+2

Characteristics:

◪ Joint point are firm and credibility

◪ Rivetless,low cost.

◪ Match the pre-pressure device,overcoming distort badly.

◪ Riveting time、pressure 、speed are all can be adjusted.

◪ National patent technology, number shows can accuracy to 0.1 second

◪ Press gently ,the molding tool loss is small

◪ Can transform into round or square

◪ The riveting area has no stress

◪ Can not break the plating or painting in surface

◪ To the metals material request not high, the copper , aluminums, steel, zinc are all unlimited

◪ Riveting process has no vibration、low noise、low consumption

◪ Unnecessary to processing in before or after riveting joint, allow to have the mezzanine and multi-layer conjunction

◪ Advanced counter and time shows window

◪ The electricity control system's operating are convenience and safety

◪ Can riveting different shapes after replaced the different die

◪ Work environment good, there is no poisonous smoke of dust exhaust, have no noise

◪ The operation simple and consume low

◪ Can design for bench type, vertical or traveling

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist