Portable safety valve test bench

Introduction

The safety valve test bench is a new type of pressure test device developed by our company for reference to GB/T 12242-2005 (pressure release device and performance test specification), which is used to adjust and test the setting pressure of the safety valve.

Function

The safety valve test bench can do the whole pressure test, the discharge pressure test, the back seat pressure test and the pressure safety performance of various relief valves.

◪ Portable safety valve test bench

System composition

◪ It consists mainly of high pressure power system, clamping device system, and so on

◪ Power system(High-pressure power source).

◪ Air driven gas booster pump-DGT60 model

◪ Driven air pressure: 3-8bar;

◪ Output gas/air pressure 0-400bar;

◪ Test medium: air, nitrogen

◪ Clamping system:

◪ The power of the clamping device is provided by a manual hydraulic(oil) pump to provide clamping pressure,Valve diameter range:DN15-DN250

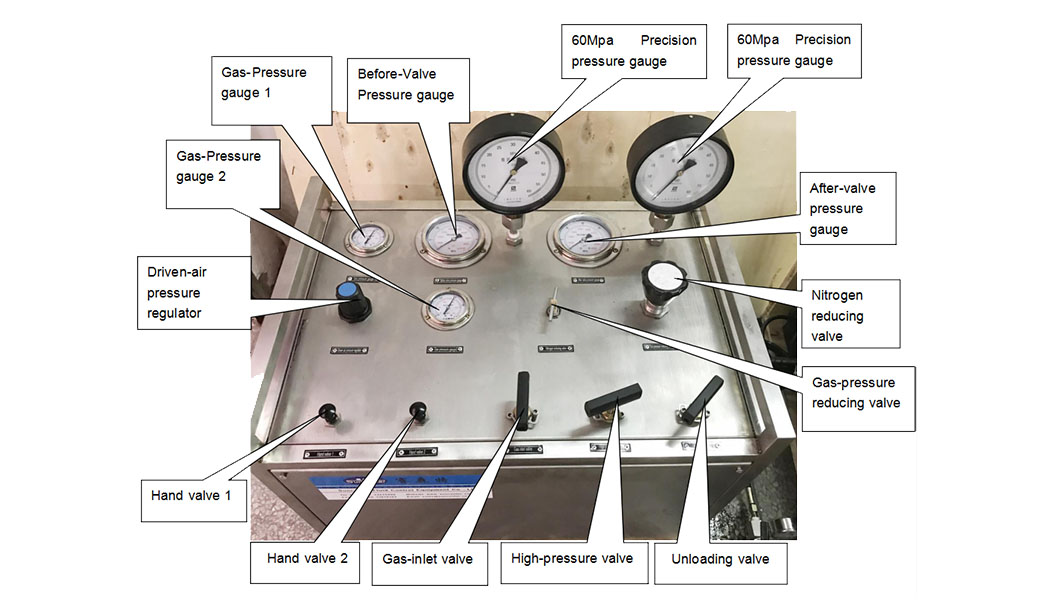

Operating panels introduction

◪ Portable safety valve test bench

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist