Contact Sales at Sunceter.

The importance of air tightness testing equipment in various major technical equipments is self-evident, especially in petroleum, chemical, metallurgy, long-distance pipelines, nuclear power, urban water supply and drainage systems and other industries.

According to data released by China Customs, the decline in the import volume of airtightness testing equipment in China in 2018 reflects the improvement in quality and technology of domestic denseness testing equipment, providing more choices for factories; and air tightness. The increase in the import value of testing equipment reflects the upgrading of domestic valve market consumption, and more and more users are more inclined to choose high-end airtight testing equipment products.

As an important part of the mechanical equipment manufacturing industry, air tightness testing equipment plays a very important role in many industries and even precision parts. In recent years, with the rapid development of China's economy and the improvement of industrial automation, the transformation and upgrading of China's equipment manufacturing industry and the country's investment in oil and gas, petrochemical, environmental protection, electric power, metallurgy and other fields continue to grow, China's air tightness Testing equipment has also developed rapidly.

At present, there are thousands of airtight testing equipment manufacturers in China. In terms of the quality of airtight testing equipment, not long ago, the provincial and municipal market supervision bureaus conducted random checks on the airtight testing equipment products used in the market. More than 90%; in terms of technological innovation, a number of industry leaders began to emerge. For example, Dongguan Suncenter Fluid Control Equipment Co., Ltd. has gradually grown into a leader in the airtightness testing equipment industry through technological innovation, and has changed the situation that China's high-end airtightness testing equipment has long relied on foreign imports in many fields.

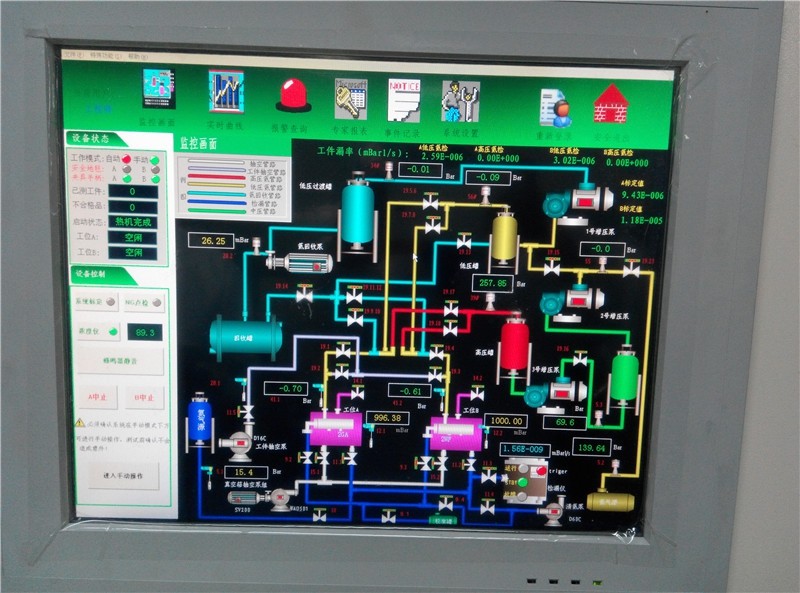

Everyone knows that the airtightness test of automotive engine parts is extremely demanding, and there is a high requirement for the sealing test of each component. Therefore, helium gas leak detection is a common detection method, but the cost of helium gas is extremely high, so Dongguan The high-pressure helium gas tightness testing equipment designed and developed by Sai Sen can not only perform airtightness testing on parts, but also recycle and recycle the tested gas, which greatly saves the use cost.

At present, China's economic situation and various policies continue to benefit, providing extremely favorable development factors for China's airtight testing equipment industry. Although there is still a certain gap between China's high-end airtightness testing equipment and foreign countries, the most important thing for China's airtight testing equipment enterprises is to further improve product quality and technical content. Only by laying a solid foundation and unremittingly exploring and innovating, China The brand of airtightness testing equipment can be heard overseas and occupy more markets.

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist