Contact Sales at Sunceter.

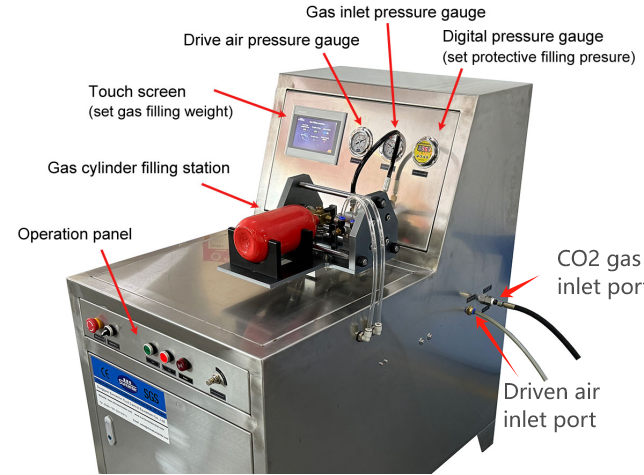

DGS-DGD25C-1 CO2 Tank Fire Extinguisher Filling Machine

introduce:

The DGS-DGD25C-1 carbon dioxide tank filling machine represents a technological leap in the field of gas filling equipment. Utilizing compressed air as a power source, this innovative machine features

a built-in pneumatic booster pump that reciprocates and pressurizes proportionally to enhance the filling process of high-pressure liquid gases. This not only significantly speeds up filling, but also ensures

automation of the filling process, precise weight control and increased efficiency. Designed for filling liquid CO2, N2O, Freon and other media, the machine is a testament to cutting-edge technology in the

field of gas handling.

Advances in electrical systems:

The core of the machine lies in the electrical system, which adopts Siemens S7-200 intelligent PLC control system. This cost-effective, compact PLC was developed by Siemens specifically for the Chinese

market and is based on the proven S7-200 series. The intelligent S7-200 integrates digital I/O points, RJ45 Ethernet port and RS485 interface into its compact body. The system has additional functions such

as high-speed counter, PID, motion control, etc., which can meet the diverse control needs of users and ensure seamless and reliable operation.

Mechanical system innovation:

The DGS-DGD25C-1's mechanical system is designed for precision and efficiency. Cylinders are securely clamped and sealed, and filled utilizing a custom-built DGD25-C booster pump. The electronic scale

automatically performs the measurement process and pauses filling when a preset weight is reached. The cylinder is then released automatically, simplifying the entire operation. Through the integration of automatic

pressure and weight control, the system not only achieves automation, but also improves filling efficiency and weight accuracy to unprecedented levels.

Steps:

set up:

Connect the air compressor and CO2 source tank to the designated ports on the right side of the machine. Adjust the drive air regulator to about 0.6MPa.

Open:

Power on the machine and enter the desired gas fill weight via the intuitive touch screen interface.

place:

Place the empty carbon dioxide tank on the refilling station, press the "Start" button, and observe whether the station clamps the cylinder securely. The machine starts the gas filling process, indicated by the filling

indicator light lighting up.

Filling process:

When the machine is running, the filling process will automatically stop when the preset weight is reached. The filling indicator light goes out and the buzzer signals completion. The workstation then automatically

releases the cylinder, marking the successful completion of the inflation task.

in conclusion:

The DGS-DGD25C-1 CO2 tank filling machine incorporates state-of-the-art technology in its electrical and mechanical systems, setting new standards for efficiency, precision and automation in gas handling.

The machine's seamless operation and user-friendly controls ensure a reliable and streamlined gas filling process, making it ideal for applications involving liquid CO2, N2O, Freon and a variety of other media.

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist