Computer Controlled Hydro Test Bench

This test bench can perform Hydrostatic test, Burst test,Leak test,Proof pressure test on the following items: Automobile steering tube, brake pipe, air-conditioning pipe, oil pipe, water pipe cooling, radiator, heater hose, hydraulic equipment, condenser, evaporator, air conditioning filter hose, turbocharging system hose, car brake pump, cylinder body, project hydraulic hose, air hose and manifold, rigid pipe, joints, valves, cylinder, pressure gauges, pressure sensor, pressure vessel, pressure transmitter, etc.

Working Principle

The test bench uses compressed air as power source, converts the 3-8 bar compressed air into higher hydraulic pressure through pneumatic liquid booster pump, and then uses the hydraulic pressure as the test medium to carry out hydro-static testing & burst testing on various items.

Features

Testing medium: Water or Oil

The test bench is designed for hydro-static testing & burst testing for various items

Wide outlet pressure range 32 - 4080 bar for your choice

Outlet pressure can be fine regulated

Equipped with protective test chamber to ensure staff safety

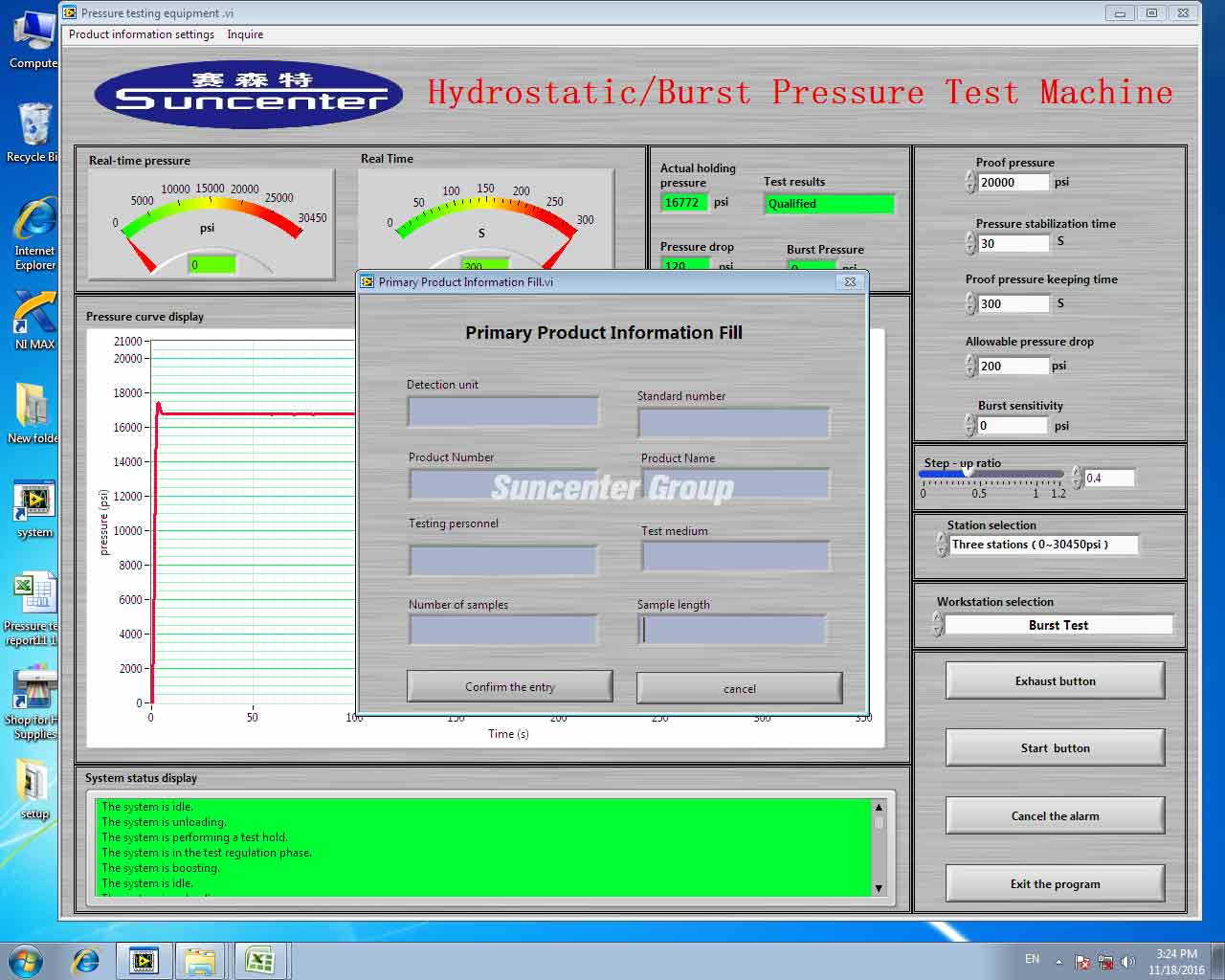

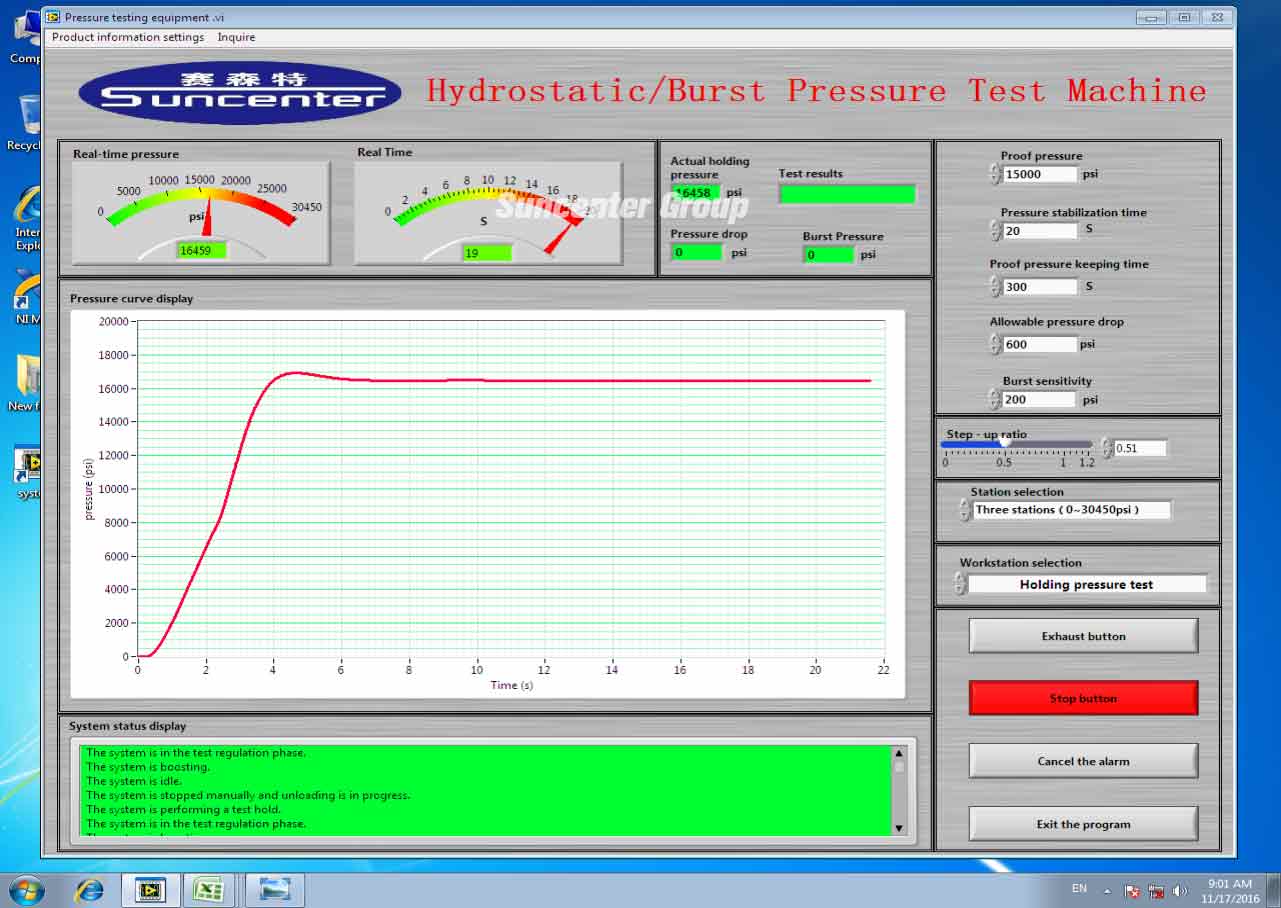

Computer control, just need preset parameter value, the computer will execute testing procedure automatically and record /analyze testing data in real time

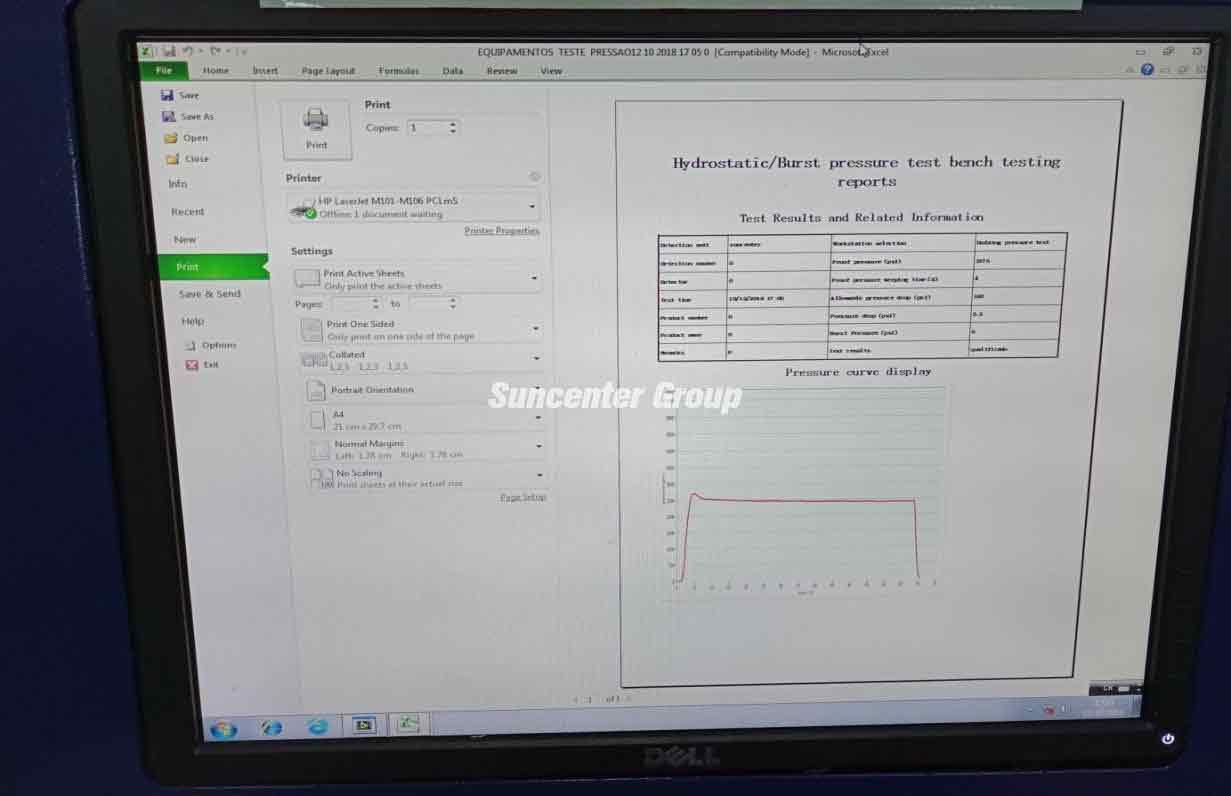

Testing data can be exported or printed

Automatic pressure maintenance during testing process, when the pressure drops, the system will automatically replenish pressure

Main Components

| Air-driven liquid booster pump | Gas dynamic duos | Pressure controller |

| Electromagnetic valve | Pressure gauge | Water injection pump |

| Water tank | Pipelines | Cabinet |

| Computer | LabView software & sensor | Ni data acquisition system |

Models & Parameters

| Model | Pressure Ratio Rate | Max Outlet Pressure | Driven-air Inlet Port | High pressure Outlet Port | Max Flow (Ln/min) |

| SHT-GD4-CC | 4:1 | 32 Bar | G 1/2 | NPT/ZG | 70 |

| SHT-GD6-CC | 6:1 | 48 Bar | G 1/2 | NPT/ZG | 48.6 |

| SHT -GD10-CC | 10:1 | 80 Bar | G 1/2 | NPT/ZG | 30.61 |

| SHT -GD16-CC | 16:1 | 128 Bar | G 1/2 | NPT/ZG | 19.73 |

| SHT-GD28-CC | 28:1 | 224 Bar | G 1/2 | NPT/ZG | 11.3 |

| SHT-GD40-CC | 40:1 | 320 Bar | G 1/2 | NPT/ZG | 7.69 |

| SHT-GD64-CC | 64:1 | 512 Bar | G 1/2 | NPT/ZG | 4.94 |

| SHT-GD80-CC | 80:1 | 640 Bar | G 1/2 | NPT/ZG | 3.96 |

| SHT-GD100-CC | 100:1 | 800 Bar | G 1/2 | NPT/ZG | 3.13 |

| SHT-GD130-CC | 130:1 | 1040 Bar | G 1/2 | NPT/ZG | 2.4 |

| SHT-GD130-CC | 175:1 | 1400 Bar | G 1/2 | NPT/ZG | 1.81 |

| SHT-GD255-CC | 255:1 | 2040 Bar | G 1/2 | NPT/ZG | 1.23 |

| SHT-GD400-CC | 400:1 | 3200 Bar | G 1/2 | NPT/ZG | 0.79 |

| SHT-GD510-CC | 510:1 | 4080 Bar | G 1/2 | NPT/ZG | 0.65 |

Remark:

(1).The flow rate above is the flow rate output by built-in hydraulic booster pump.

(2).There is an electric water injection pump built in the test bench ( flow rate 30L-100L/Min).

(3).To speed up the testing progress, firstly you could activate the electric pump to fill normal flowing water into testing item, then activate the hydraulic booster pump to generate high pressure liquid and inject it into the test item.

Software Operation Interface

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved