Cylinder Valves Leak Test Bench

Gas cylinder valve leak test bench uses high-pressure air or gas to perform proof pressure test, gas tightness test, and leakage test on various pressure vessels' valves such as gas cylinder valves and fire extinguisher valves. This machine is driven by air compressor and does not require electric power, with maximum output pressure 800Bar. And the machine is equipped with 2 workstations, which can carry out air tightness testing on two bottle valves at same time.

Features

Applicable to various gas cylinder valves for air tightness test

Automatic pressure lock and pressure maintenance, the machine will automatically stop and enter pressure maintenance stage when preset pressure is reached, and it will automatically replenish pressure in case of end pressure drop

Powered by 3-8 bar compressed air, no electric power required

Maximum testing pressure 80MPa and outlet pressure can be fine regulated

Multi-station can be customized to improve test efficiency

Main Technical Parameter

Pressure range: 0—800Mpa

Test medium: air / gas

Test object: gas cylinder valves & fire bottle valves

Detection method: bubbling method detection

Operation mode: manual control

Timing method: manual timing

Power source: 3-8 bar compressed air

Test process: pressurize -pressure holding - pressure unload

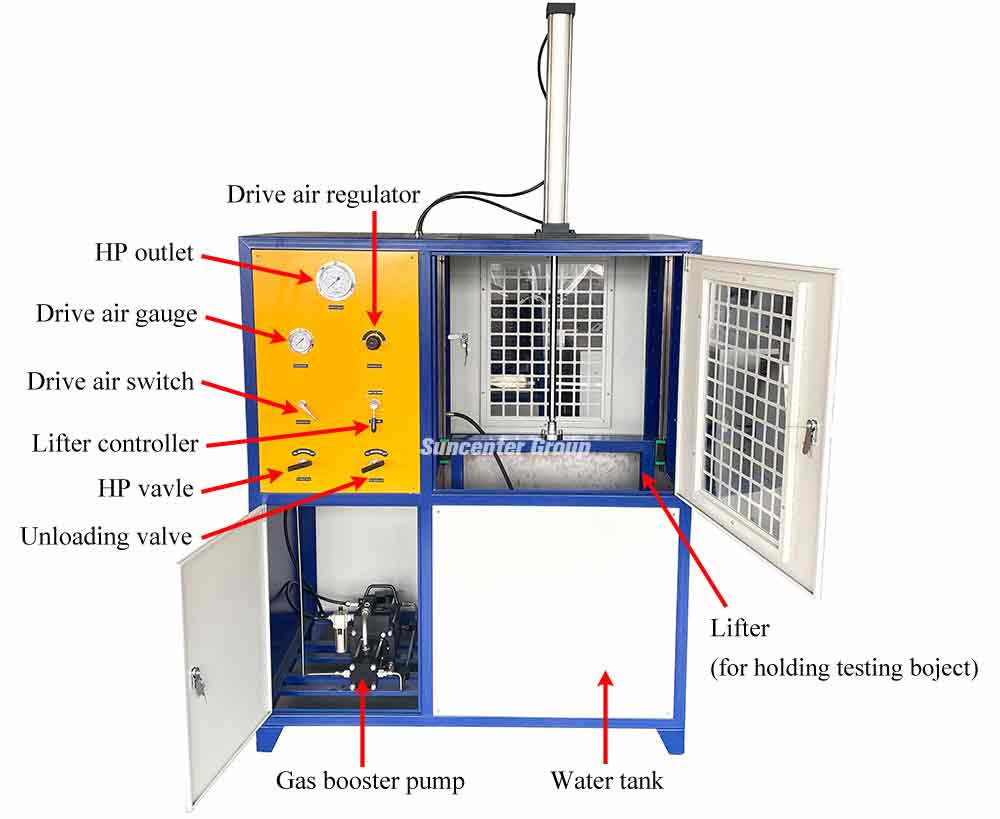

Main Components

The air tightness testing machine is composed of gas booster pump, pressure control unit, water tank, lifting basket, valve tooling fixture, etc.

The gas booster pump is driven by 3-8bar compressed air, and it can output maximum 800Bar, which is the source of high-pressure gas for air tightness testing. The cylinder valve tooling fixture is installed at the bottom of the lifting basket which can be immersed in the water tank driven by the pneumatic cylinder.

Operation Steps

(1). Place your testing object into Protective test chamber and connect it onto HP outlet port with hose, then close the chamber’s door

(2).Install the bottle valve on the bottle valve tooling, immerse the lifting guide rail in the water tank, and close the warehouse door

(3).The test pressure value is preset on the control panel, and the pneumatic booster pump starts to pressurize and inject high-pressure gas into the bottle valve;When the preset pressure value is reached, the pneumatic booster pump will automatically stop and enter the maintenance stage

(4).Manual timing, and then observe the water tank through the explosion-proof door. If there is no bubble coming out, it means that the air tightness of the bottle valve is qualified. If there are bubbles in the water tank, it means that the airtightness of the bottle valve is not qualified.

(5).Open the pressure relief valve to discharge the high-pressure gas to the outside, raise the guide rail, remove the bottle valve, and the test is over.

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist