Manual & Digital Safety Valve Test Bench

Technical Parameters

Safety valve test bench is used for various safety valve setting pressure adjustment, the whole set pressure detection, discharge pressure detection, back seat pressure testing, assessment of its pressure safety performance etc.

Pressure range: 0-400 bar for option (gas pressure and water pressure)

Test medium: Air, Nitrogen, Water

Test valve diameter: DN15-DN400 for option

Pressure control accuracy: less than 1%F.S

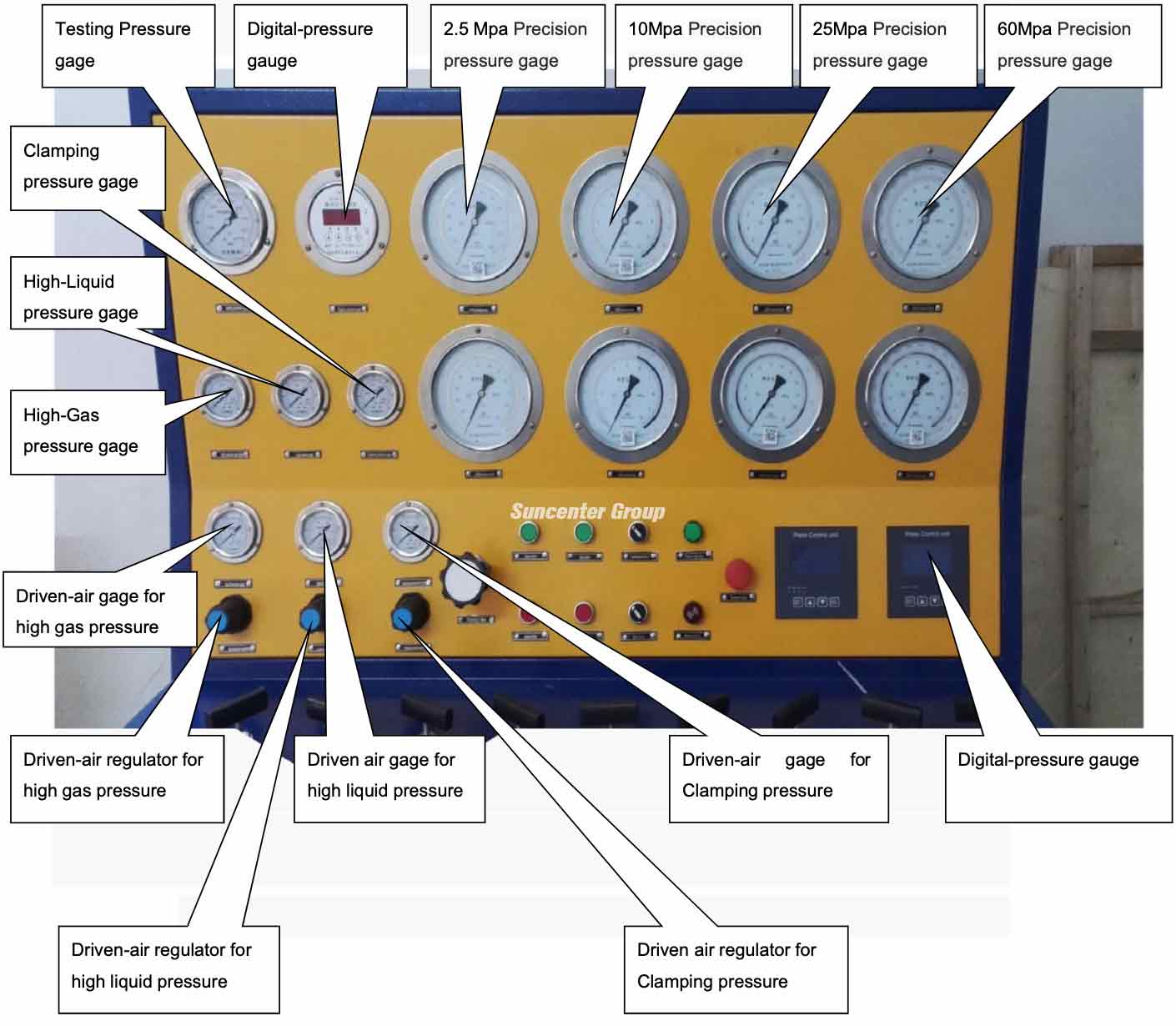

Pressure measurement accuracy: 0.4 pressure gauge

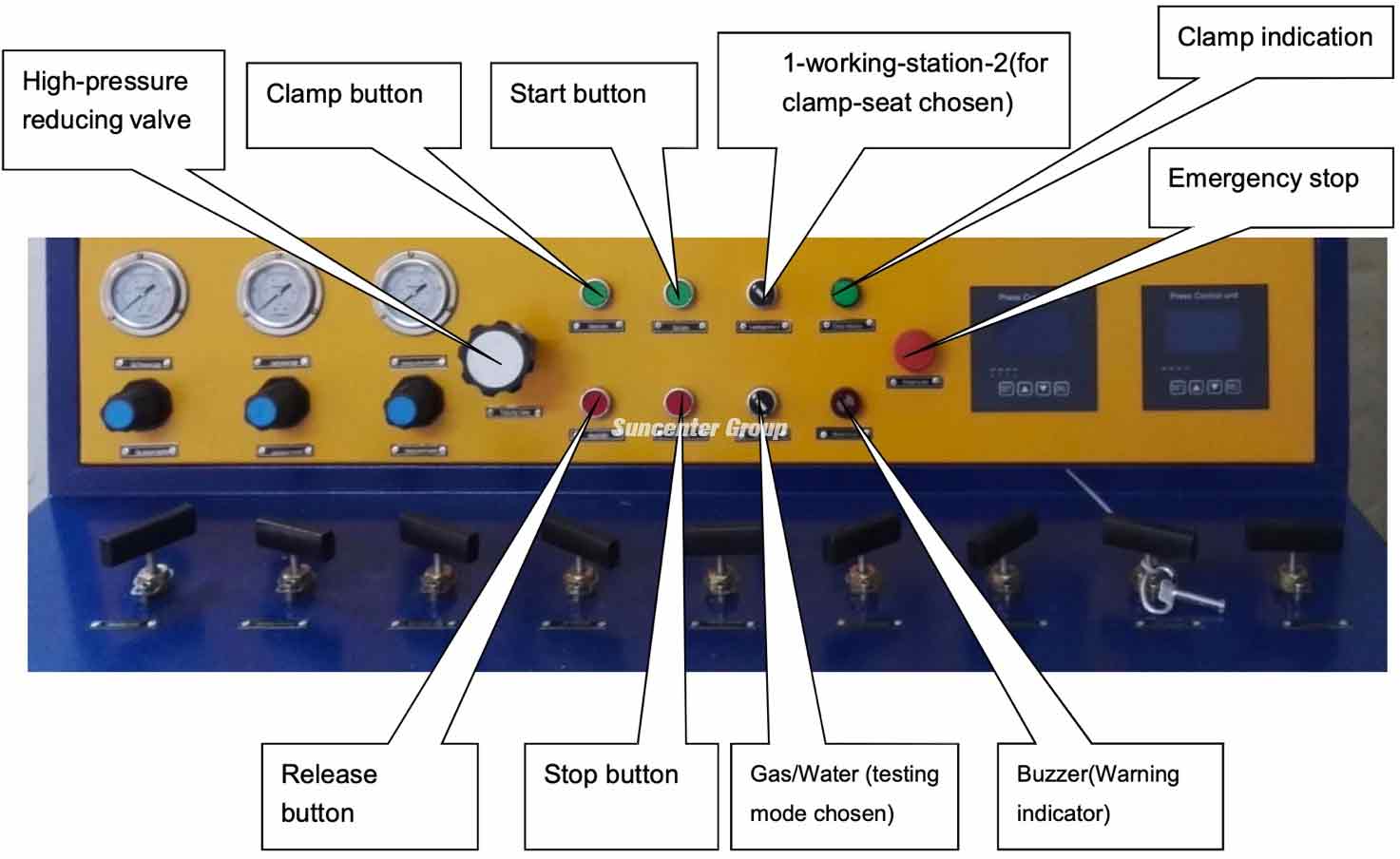

Clamping way: Hydraulic cylinder clamping

Station interface type: screw and flange type

Clamping force output range: 0-50 tons

Supply voltage: 50Hz -60Hz ,220V/380V for option

System Composition

1). Power system (High-pressure power source):

Air-driven gas booster pump DGT60: output gas/air pressure 0-480bar

Air-driven liquid pump DGG64: output liquid pressure 0-512bar

2). Clamping system:

0-32 MPa output pressure clamping system power provided by Air-driven liquid boost pump DGGD40, fully meet the clamping force of the pressure relief valve safety valve with specification requirements; the corresponding connection fixture is connected with the high-pressure pump gas pipeline; ensure that the measured cylinder packing seal between the member and the pipeline, 2 separate operations.

3). Data acquisition test system:

The pressure acquisition system is composed of real-time pressure - time change, and the pressure - time curve is automatically drawn.

Pressure sensor: setting four stage sensor according to pressure section

Pressure range: 0-2.5MPa, 0-16MPa, 0-40MPa, 0-100MPa

The performance index is up to + 0.5%FS precision, and the range is compared with 100:1.

4). Electrical control and output system:

Software: the use of LabView programming, independent development of software programs. The data of pressure and time are transferred to the computer uniformly through the acquisition card. The computer displays, amplifies, records and forms curves for all data, and all data can be printed by printers. High precision is guaranteed under high sampling rate.

Main components

| Item | Name | Specification | Unit | Quantity |

| 1 | Pneumatic gas booster pump | DGT60 | set | 1 |

| 2 | Pneumatic liquid booster pump | DGG64 | set | 1 |

| 3 | Pneumatic liquid booster pump (hydraulic oil) | DGGD40/DGM44 | set | 1 |

| 4 | F.R.L combination | pc | 2 | |

| 5 | Two position three way solenoid valve | pc | 2 | |

| 6 | Compression cylinder | pc | 1 | |

| 7 | Manual needle valve | 0-2.5MPa | pc | 12 |

| 8 | Precision pressure gauge | 0-10MPa | pc | 2 |

| 9 | Precision pressure gauge | 0-25MPa | pc | 2 |

| 10 | Precision pressure gauge | 0-60MPa | pc | 2 |

| 11 | Precision pressure gauge | 0-2.5MPa | pc | 2 |

| 12 | Pressure transmitter | 0-10MPa/0.5% | pc | 1 |

| 13 | Pressure transmitter | 0-40MPa/0.5% | pc | 1 |

| 14 | Pressure transmitter | 0-60MPa/0.5% | pc | 1 |

| 15 | Pressure transmitter | pc | 3 | |

| 16 | Pipeline connection fittings | batch | 1 | |

| 17 | Electromagnetic directional valve | set | 2 | |

| 18 | Clamping device | set | 1 |

Clamping Seat

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist