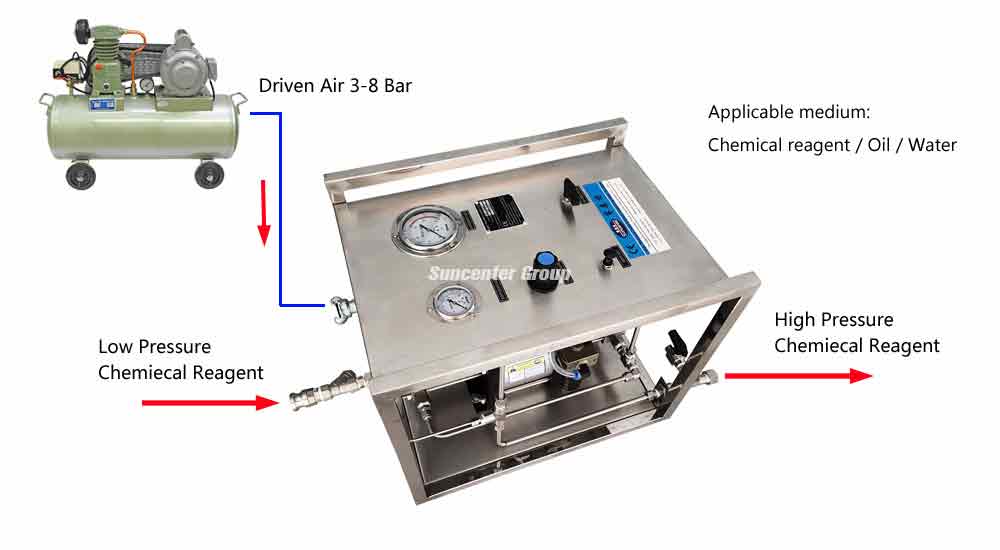

Pneumatic Chemical Reagent Injection System

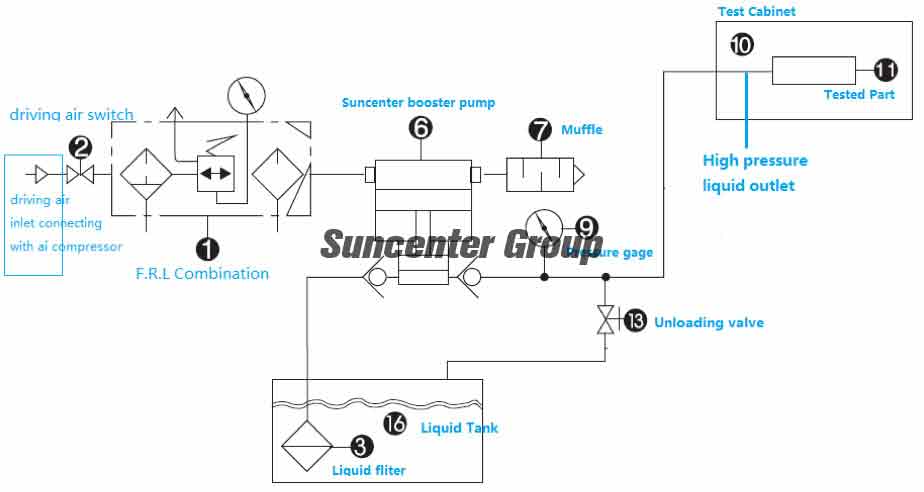

Working Circuit

Circuit Principle

Chemical Injection System = Liquid boost pump + Valves + Gauges + Tubes + Cart

Composition of Standard Chemical Injection System

Liquid boost pump (DGG/DGGD/2DGGD three series for choosing)

F.R.L combination for driven air (adjust air pressure + add lubricating oil + filter function)

Driven air switch, driven air pressure gauge

High pressure needle valve, High pressure gauge, unload valve, Interconnecting pipes, etc.

Trolley ( There types options)

DLS-DGG Series

| Model | Pressure boost ratio | Driven air pressure | Max outlet pressure | Driven air inlet port | Liquid inlet port | Liquid outlet port | Max Flow rate (L/min) |

| DLS-DGG7 | 7:1 | 3-8 bar | 56 bar | G 1/2 | PT 1/2 | PT 1/2 | 26 |

| DLS-DGG10 | 10:1 | 3-8 bar | 80 bar | G 1/2 | PT 1/2 | PT 1/2 | 18.84 |

| DLS-DGG16 | 16:1 | 3-8 bar | 128 bar | G 1/2 | PT 1/2 | PT 1/2 | 12.42 |

| DLS-DGG28 | 28:1 | 3-8 bar | 224 bar | G 1/2 | PT 1/2 | PT 1/2 | 7.11 |

| DLS-DGG40 | 40:1 | 3-8 bar | 320 bar | G 1/2 | PT 3/8 | PT 3/8 | 4.89 |

| DLS-DGG64 | 64:1 | 3-8 bar | 512 bar | G 1/2 | PT 3/8 | PT 3/8 | 3.08 |

| DLS-DGG80 | 80:1 | 3-8 bar | 640 bar | G 1/2 | PT 3/8 | PT 3/8 | 2.44 |

| DLS-DGG100 | 100:1 | 3-8 bar | 800 bar | G 1/2 | PT 3/8 | PT 3/8 | 1.92 |

| DLS-DGG130 | 130:1 | 3-8 bar | 1040 bar | G 1/2 | PT 3/8 | PT 3/8 | 1.47 |

| DLS-DGG175 | 175:1 | 3-8 bar | 1400 bar | G 1/2 | PT 3/8 | PT 3/8 | 1.14 |

| DLS-DGG240 | 240:1 | 3-8 bar | 1920 bar | G 1/2 | PT 3/8 | PT 3/8 | 0.86 |

DLS-DGG300 | 300:1 | 3-8 bar | 2400 bar | G 1/2 | PT 1/4 | HF 4 | 0.72 |

| DLS-DGG400 | 400:1 | 3-8 bar | 3200 bar | G 1/2 | PT 1/4 | HF 4 | 0.48 |

| DLS-DGG510 | 510:1 | 3-8 bar | 4080 bar | G 1/2 | PT 1/4 | HF 4 | 0.70 |

DLS-DGGD Series

| Model | Pressure boost ratio | Driven air pressure | Max outlet pressure | Driven air inlet port | Liquid inlet port | Liquid outlet port | Max Flow rate (L/min) |

| DLS-DGGD4 | 4:1 | 3-8 bar | 32 bar | G 1/2 | PT 1/2 | PT/NPT 1/2 | 70 |

| DLS-DGGD6 | 6:1 | 3-8 bar | 48 bar | G 1/2 | PT 1/2 | PT/NPT 1/2 | 48.6 |

| DLS-DGGD10 | 10:1 | 3-8 bar | 80 bar | G 1/2 | PT 1/2 | PT 1/2 | 30.61 |

| DLS-DGGD16 | 16:1 | 3-8 bar | 128 bar | G 1/2 | PT 1/2 | PT 1/2 | 19.73 |

| DLS-DGGD28 | 28:1 | 3-8 bar | 224 bar | G 1/2 | PT 1/2 | PT 1/2 | 11.3 |

| DLS-DGGD40 | 40:1 | 3-8 bar | 320 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 7.69 |

| DLS-DGGD64 | 64:1 | 3-8 bar | 512 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 4.94 |

| DLS-DGGD80 | 80:1 | 3-8 bar | 640 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 3.96 |

| DLS-DGGD100 | 100:1 | 3-8 bar | 800 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 3.13 |

| DLS-DGGD130 | 130:1 | 3-8 bar | 1040 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 2.4 |

| DLS-DGGD175 | 175:1 | 3-8 bar | 1400 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 1.81 |

| DLS-DGGD240 | 240:1 | 3-8 bar | 1920 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 1.5 |

| DLS-DGGD300 | 300:1 | 3-8 bar | 2400 bar | G 1/2 | PT 1/4 | PT/NTP 1/4 | 1.3 |

| DLS-DGGD400 | 400:1 | 3-8 bar | 3200 bar | G 1/2 | PT 1/4 | PT/NTP 1/4 | 0.79 |

DLS-2DGGD Series

| Model | Pressure boost ratio | Driven air pressure | Max outlet pressure | Driven air inlet port | Liquid inlet port | Liquid outlet port | Max Flow rate (L/min) |

| DLS-2DGGD10 | 10:1 | 3-8 bar | 80 bar | G 1/2 | PT 3/4 | PT 3/4 | 61.22 |

| DLS-2DGGD16 | 16:1 | 3-8 bar | 128 bar | G 1/2 | PT 3/4 | PT 3/4 | 39.46 |

| DLS-2DGGD28 | 28:1 | 3-8 bar | 224 bar | G 1/2 | PT 1/2 | PT 1/2 | 22.6 |

| DLS-2DGGD40 | 40:1 | 3-8 bar | 320 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 15.38 |

| DLS-2DGGD64 | 64:1 | 3-8 bar | 512 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 9.88 |

| DLS-2DGGD80 | 80:1 | 3-8 bar | 640 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 7.92 |

| DLS-2DGGD100 | 100:1 | 3-8 bar | 800 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 6.26 |

| DLS-2DGGD130 | 130:1 | 3-8 bar | 1040 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 4.8 |

| DLS-2DGGD175 | 175:1 | 3-8 bar | 1400 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 3.62 |

| DLS-2DGGD240 | 240:1 | 3-8 bar | 1920 bar | G 1/2 | PT 3/8 | PT/NPT 3/8 | 2.5 |

| DLS-2DGGD300 | 300:1 | 3-8 bar | 2400 bar | G 1/2 | PT 1/4 | PT/NTP 1/4 | 2.2 |

| DLS-2DGGD400 | 400:1 | 3-8 bar | 3200 bar | G 1/2 | PT 1/4 | PT/NTP 1/4 | 1.58 |

How to Select Chemical Injection System ?

Just tell us the following parameters, we will match proper model for you:

1.What kind of chemical reagent do you want to inject ?

2.What is the max outlet working pressure do you need? ( ) bar

3.What outlet flow do you need? ( ) L/min

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist