Contact Sales at Sunceter.

As we all know, the refrigerant transportation equipment is mainly used for the transportation of various refrigerants such as R22, R134a, R407C and R410A. However, due to the need to transport the refrigerant central transporting station over a long distance, how to save the refrigerant transport on the production line, change the gas storage tank, save manpower, and reduce the waste of refrigerant has become an urgent problem in the pump and valve industry.

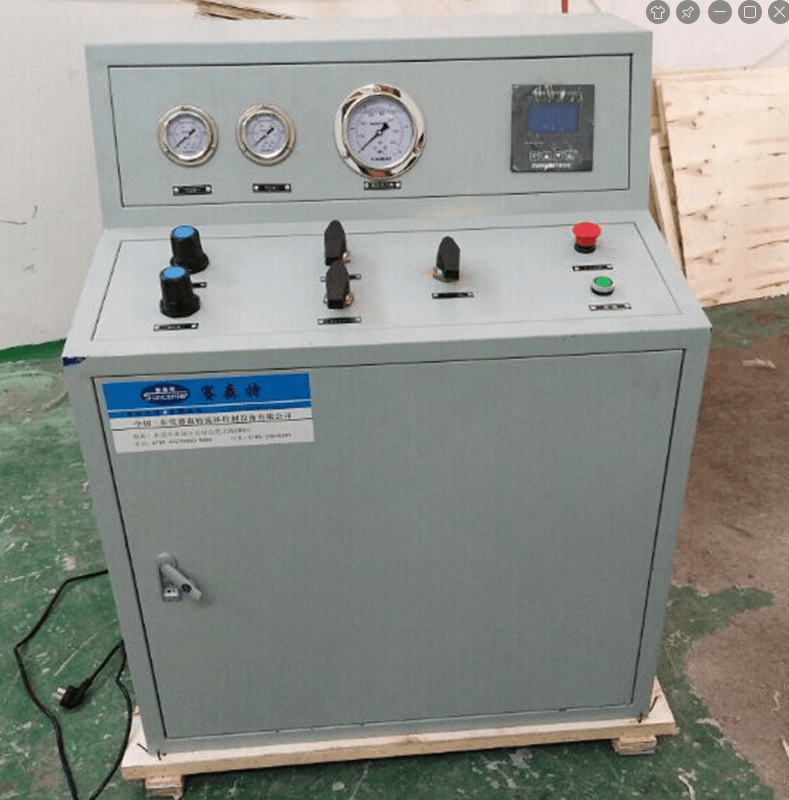

In order to solve the above problems, Suncenter refrigerant filling and transportation equipment came into being. The refrigerant filling and transporting equipment is not only easy to operate, but also easy to maintain and has a long-distance conveying capability. In terms of maintenance, the components are compact and have no dead ends, which is convenient for users to clean. It is also an energy-saving and efficient machine. It adopts single air-controlled unbalanced gas distribution valve to realize automatic reciprocating motion of the pump. It is fully pneumatically operated, requires no power supply, fully automatic work, saves manpower and has a long service life. It can satisfy customers. High-intensity work requirements.

In addition, the Suncenter refrigerant filling and transportation equipment is still quite different from the current refrigerant transportation equipment on the market.

First, the degree of rust. The pump body part of the pump body is all made of aluminum alloy, and the aluminum alloy parts are processed and oxidized to black, which ensures the appearance and never rust of the Suncenter refrigerant conveying equipment, in the process of use, Not susceptible to the environment, even in wet weather, there will be no rust.

Second, the length of life. Since the refrigerant charging and transportation equipment does not rust when it is used, the equipment does not accelerate aging due to rust. However, in the case of ordinary refrigerant charging pumps, rusting is likely to occur during use, thereby accelerating aging and shortening the service life of the equipment.

Third, maintenance operations. Since the refrigerant charging and transportation equipment does not rust when it is used, it is not required to perform rust prevention operations, which also reduces the maintenance procedure for the user. In contrast, ordinary refrigerant filling pumps can not avoid rust and rust removal operations when used.

Therefore, the maintenance operation of the conventional refrigerant charging pump has a lot of maintenance operations on the refrigerant charging and transportation equipment, and its maintenance cost is relatively high.

At present, there are many types of refrigerant filling pumps in the market. When users purchase pump valves, they often suffer. The industry analysts analyze that this is mainly due to the uneven market prices and various brands. Other experts also said that there are some problems in the market for refrigerant charging pumps that need to be resolved. For example, some small processing plants, which are in the gray area, copy the large-scale refrigerant filling pump, which not only disturbs the market order, but also hinders the healthy development of the industry. Suncenter once again reminded that when choosing a refrigerant filling pump, the user needs to polish his eyes, to consider the quality, performance and technical level of the equipment, but also to consider the corporate brand, corporate services, etc. Good quality, good performance refrigerant filling transportation equipment.

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist