Contact Sales at Sunceter.

Suncenter's Cylinder Hydrostatic Testing Machine, specifically designed for gas cylinders, offers seamless testing for a variety of steel cylinders.

This includes nitrogen cylinders, argon helium cylinders, oxygen cylinders, hydrogen cylinders, carbon dioxide cylinders, and LPG/LNG/CNG

winding bottles, among others. The equipment, computer-controlled and featuring an HP printer for direct test report printing, employs a double

water jacket for oxygen bottles and other cylinders. It is widely utilized in testing station cylinder jacket methods for hydrostatic test evaluations.

Pressure Range: 80 bar—640 bar

Experimental Medium: Water

Test Accuracy: ±0.5%FS

Driven Air Pressure: 3bar-8bar

Timing Range: 0-999h

Outlet Flow: 30.61 L/min

Power Device: DGGD80 model Air Driving Liquid Pump

Control Mode: Computer Controlling

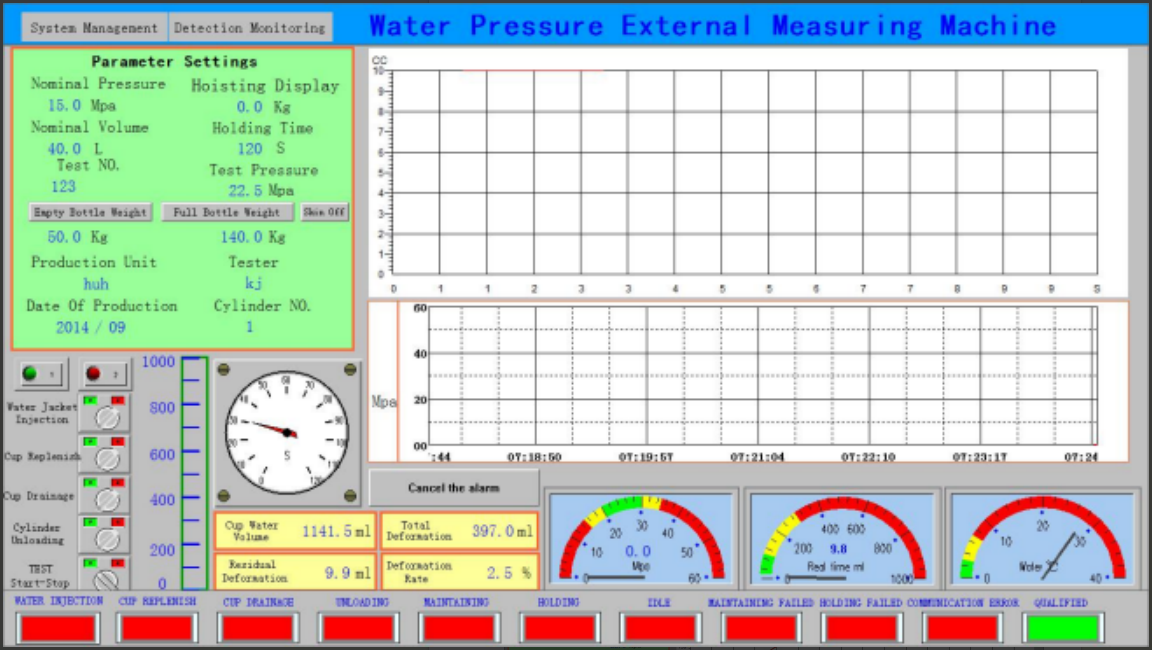

Testing Software: LabVIEW SW

Collection Electric Control: American NI Acquisition Card

FR.L Combination: UFRL04 Solenoid Valve (Sanlixin)

Pressure Transmitter: Tianmu Series

Pressure Gauge: KEMAI

Pipe Joint: Stainless Steel

Main Cabinet Size: 140150100cm

This machine is primarily employed for cylinder pressure testing and determining the gas cylinder volume residual deformation rate. The working principle

involves placing the cylinder into a water jacket and pressurizing it using a high-pressure pump. The system automatically dwells at the set pressure,

conducting a pressure test on the cylinder. Simultaneously, the cylinder volume expands under the test pressure, squeezing water from the water jacket into

a measuring cup to assess cylinder volume deformation.

The water collected during the test is transferred to a PC via the water collection system. After the cylinder is relieved of pressure, the elastic deformation disappears,

and the water flows back from the measuring cup to the water jacket. However, the remaining water in the measuring cup exceeds the initial volume before boosting

the cylinder. This excess water volume represents the gas cylinder volume residual deformation.

The gas cylinder volume residual deformation rate is then calculated as the ratio of the test gas cylinder volume residual deformation to the total deformation.

This comprehensive testing system ensures accurate and reliable evaluation of cylinder integrity, making it an indispensable tool for various industries.

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist