RY heat conduction oil pump unit bearing damage ten reasons and solutions

by:Suncenter

2020-09-12

First, RY heat conduction oil pump unit bearing load, overload.

Solution: reduce the load or redesign, so system geomagnetic overload, can try to again choose bearing;

Short-term overload and impact load system, specialized processing can be managed to increase lubrication, bearing, etc.

Second, RY high temperature, heat conduction oil co2 transfer pump electric unit bearing overheating - this is a performance.

As 'fever'.

Signs are raceway, the ball and cage becomes angry, - mild lubricant change color from gold to blue, even attached on the raceway or roller.

Severe bearing parts of the blue color.

Bearing parts of the heavy metal flow.

Temperature more than 400 f make material of raceway and rolling element annealing -- it is said that the influence of high temperature mechanical properties of bearing.

Hardness decrease results in the decrease of bearing load - bearing raceway and early failure or roller hardness below HRC58, life expectancy will be lower.

Solution: bearing run run on viscosity of lubricant;

Temperature rise will reduce viscosity of lubricant, and even affect its basic chemical properties.

Third, heat conduction oil pump unit bearing false cloth type dent, 'pseudo brinell indentation'.

In each ball wear position of oval dent, smooth, with clear boundary, grinding - shape is not always around.

Such damage is in commonly no grinding traces in the indentation.

Solution: isolation and use of antifriction additives - usually caused by flutter in transit.

Fourth, the heat conduction oil pump unit bearing cloth type indentation hardness -- 'true brinell indentation'.

When the load exceeds the elastic limit of the raceway, usually caused by the radial impact load.

The dent roller path to increase vibration (

Noise)

Solution: static load and the serious impact to produce cloth dent, such damage generally within the indentation left traces of grinding.

Fifth, normal fatigue failure, fatigue damage.

RY heat conduction oil pump unit bearing fatigue failure occur on the raceway and rolling body fracture, and the resulting material falling debris, including fatigue fracture and fatigue spalling.

The fatigue to gradually, once you start is expanding quickly, and with obvious vibration increase - hardening steel generally is expanding quickly, easy to cause damage of instantaneous.

The development of carburizing steel will have a long time.

Solution: change the bearing, and long fatigue life of bearing is designed, should say selects high rated dynamic load bearing, high purity of bearing steel and so on.

Sixth, RY heat conduction oil pump reverse load - abnormal load.

The design of angular contact bearings only accept a direction of axial load when in the opposite direction, outer elliptical contact area was made.

。

。

The result is stress increases, temperature, and generate vibration increases and premature failure of the bearing, heat conduction oil pump bearing internal contamination - 7 mean foreign matter.

Pollution is one of the leading causes of bearing failure signs of pollution is on the surface of raceway and rolling element a little mark, leading to vibration increase and wear solution: clean environment, tools, standardize the operation.

A new bearing of storage and transportation.

Eighth, heat conduction oil pump failure - bearing inner lubricating oil lubrication failure.

Heat conduction oil pump bearing raceway and roller color (

Blue, brown)

Be a sign of lubrication failure, the resulting, roller and cage wear and lead to overheating and a serious fault.

- early raceway surface glass type.

The normal operation of the rolling bearing failure often depends on the good oil film between parts caused by insufficient lubrication and overheating - but there is an error of lubrication (

Lubricant too much, too little, silk, too thin)

And invalid lubrication (

Error of lubrication, oil, failed to timely change)

Two reasons.

Ninth, heat conduction oil pump hearts different partial load for a long time.

No signs of ball rolling on the grinding crack parallel to the raceway edge not if not more than 0.

001 in/in, can produce bearing and bearing abnormal temperature rise, and keep the ball wear - different bearing types have different allow partial loads.

General self-aligning bearing has good partial load ability.

But other bearings can through the optimization of raceway geometry size and achieve the goal of adding partial load capacity.

The tenth, corrosion - foreign body into a, water.

Its symptom is in raceway, roller, cage or other position appears red brown areas - early rust color, general common black.

Reason is that the bearing contact corrosive fluid and gas severe cases, the bearing earlier fatigue failure caused by corrosion solution: remove corrosive fluid, as far as possible using the sealed bearing - sealed bearing is not preferred.

Each bearing has a sealing system, the key is to make it effective.

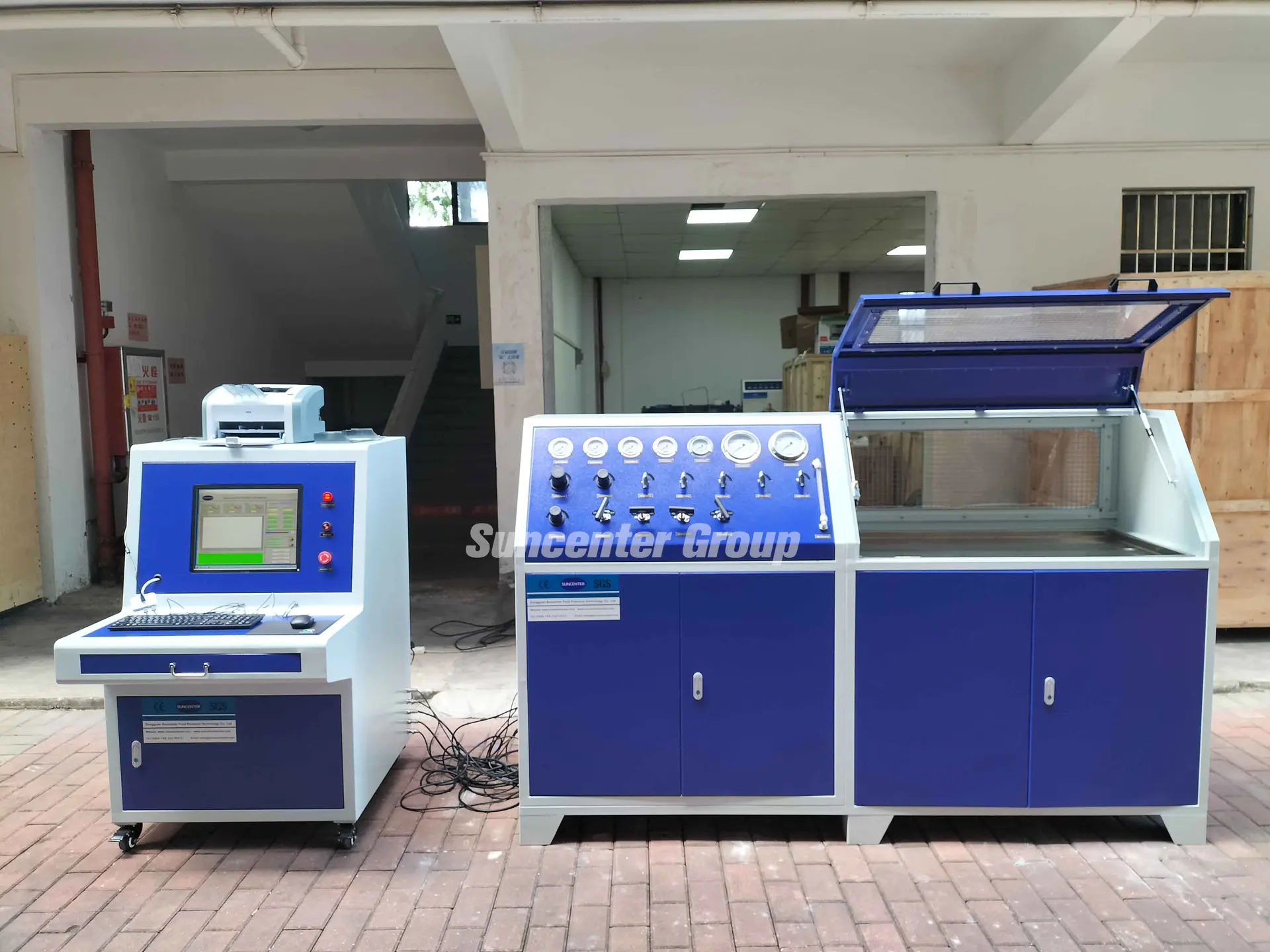

RY air-cooled high temperature heat conduction oil pump adopts the heat radiating structure, changed the conventional water cooling structure, make the simple structure, small volume, save operating cost, good performance, use, is our country on the basis of digesting and absorbing foreign oil pump of the second generation product, this type co2 transfer pump belongs to high risk product, belongs to the scope of the national production license to do not buy products without a license, in order to avoid has the danger, use process query the authenticity of a production license can be used to query website of China technology supervision and case number be applied.

Key words: oil pump power plant, oil co2 transfer pump unit equipment, electric pump power plant manufacturers

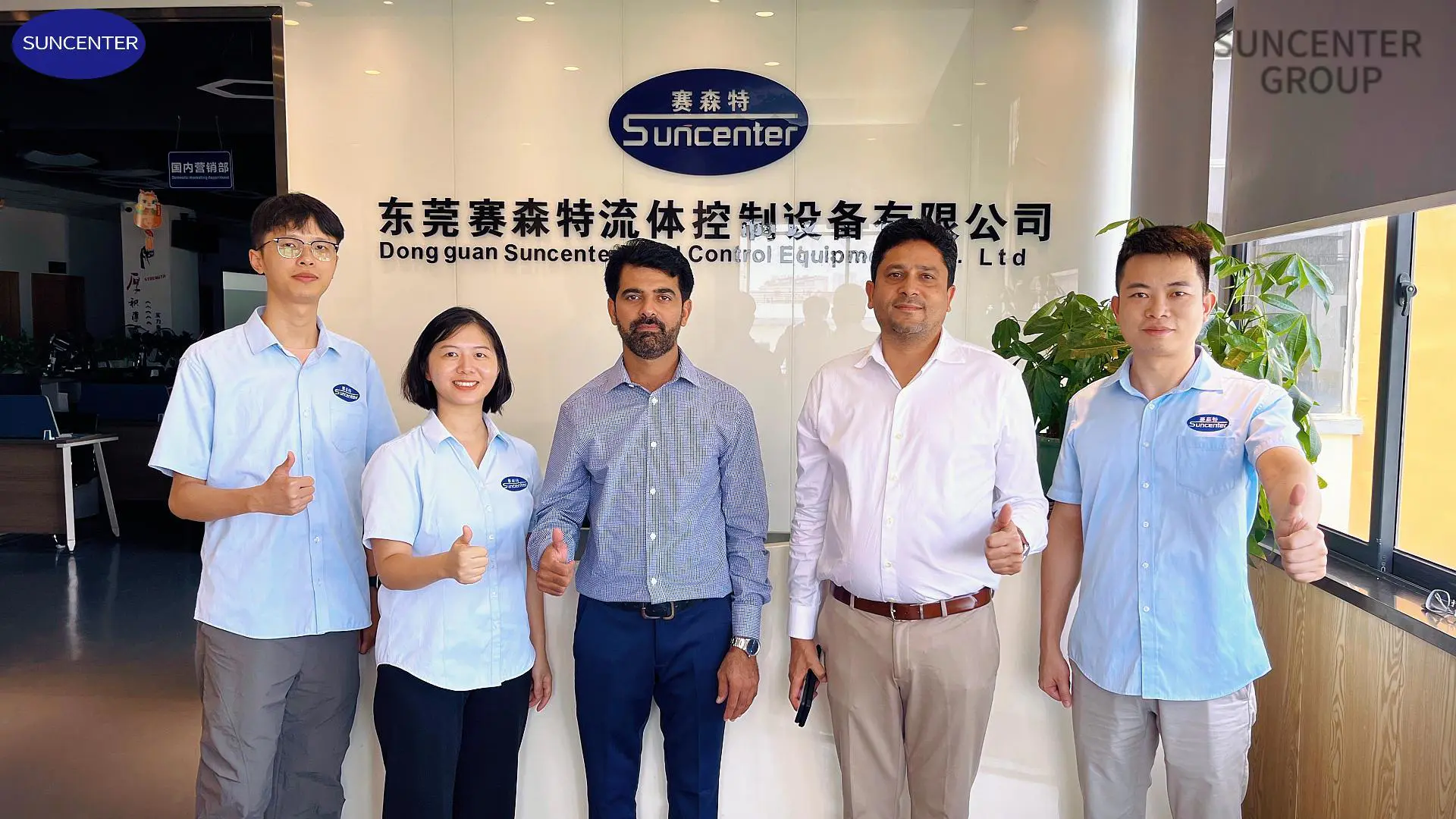

Additionally, Dongguan Suncenter Fluid Control Equipment Co., Ltd has a few new features planned to roll out in the app to provide more convenience, comfort and options to our clients.

You can get a of any specification from Dongguan Suncenter Fluid Control Equipment Co., Ltd as we have varied specifications to suit different hydraulic pressure pump needs and cater to a wide client base existing in both domestic and overseas market. please feel free to enquire us at Suncenter Fluid Control Equipment.

By investing in an ethical supply chain, Dongguan Suncenter Fluid Control Equipment Co., Ltd position ourselves to engage with a driven, engaged customer base.

It is one of the best products available in the market today. gas booster is famous product in many oversees market.

Additionally, Dongguan Suncenter Fluid Control Equipment Co., Ltd has a few new features planned to roll out in the app to provide more convenience, comfort and options to our clients.

You can get a of any specification from Dongguan Suncenter Fluid Control Equipment Co., Ltd as we have varied specifications to suit different hydraulic pressure pump needs and cater to a wide client base existing in both domestic and overseas market. please feel free to enquire us at Suncenter Fluid Control Equipment.

By investing in an ethical supply chain, Dongguan Suncenter Fluid Control Equipment Co., Ltd position ourselves to engage with a driven, engaged customer base.

It is one of the best products available in the market today. gas booster is famous product in many oversees market.

Custom message