Tell you about variable plunger pump problems and treatment methods

by:Suncenter

2020-09-04

Tell you about variable plunger pump manufacturer problems and processing method of the oil temperature is too high to dispel methods: 1.

Increase the tank volume, or increase the cooling assembly in the variable piston pump manufacturer.

2.

Appropriate to reduce the oil viscosity or the oil change.

3.

Inspection or changing pump, valve and related parts.

4.

The wearing parts, inspection or change re-election fit clearance.

Serious dispelling method: 1.

Light person after rubbing and polishing process, the successors.

When worn, slipper and block can end flat grinding, and the oil distribution disc and variable head should be changed.

2.

Spline shaft, should guarantee the proper set of fit clearance.

3.

Piston and cylinder should guarantee proper fit clearance.

4.

Remove the pump body and shaft end, make the drive shaft spline below the cylinder block.

5.

In slipper with plunger, riveting timeliness should guarantee proper axial clearance.

6.

body is assembled, and the shaft alignment should guarantee within the specified error.

7.

body flow with the plane and the pump shell used for assembling large bearing aperture plane, absolute shaft axis perpendicularity should guarantee within the specified error.

8.

Check the seal and shaft end skeleton oil seal, such as have crushed damage, should change in time.

Servo variable institutions or pressure compensation variable mechanism motion failure reason cause: 1.

Oil flow channel by impurities, dirt.

2.

Check valve spring break.

3.

Head and variables between the bearing bush of arc on the shell surface wear serious, transmission is not flexible.

4.

Variable institutions the rest badly worn or damaged parts.

Reassure methods: 1.

Variable mechanism assembly parts to wash, dredge the channel.

2.

Change in the check valve spring.

3.

Light person scraping, inheritances.

As two circular arc surface wear serious when should change, change its migration.

4.

Check the rest of the parts, such as badly worn or damaged, should be timely change.

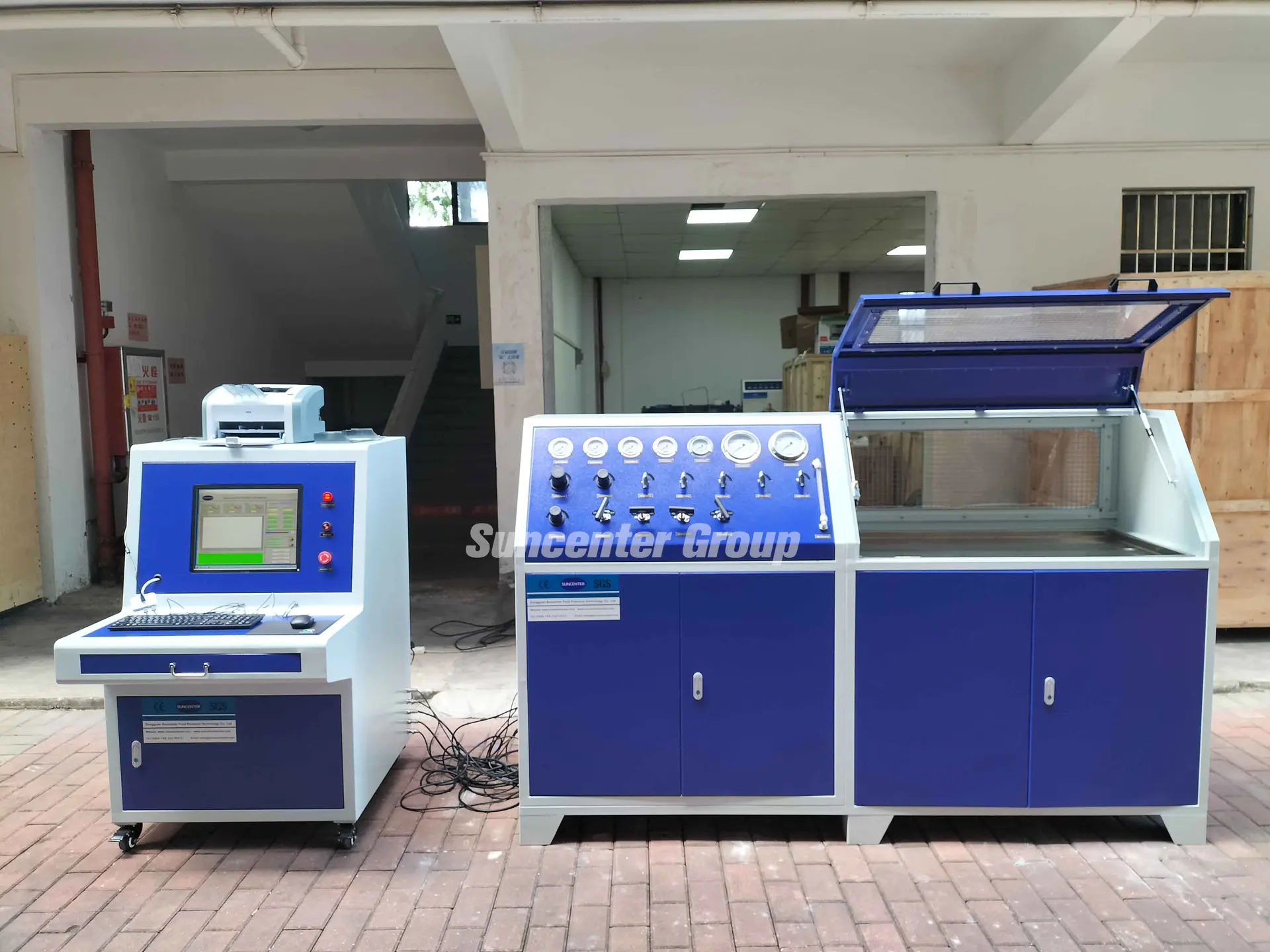

Keywords: variable plunger pump manufacturers, variable plunger co2 transfer pump manufacturers, axial variable piston pump manufacturer

For business owners unsure of how to effectively incorporate new technology into our gas booster, life may have just become a little easier.

We believe our ability can raise a giant wave of innovation among the field of gas booster.

Another way to maintain the professional yet engaging innovative technology in gas booster is by embedding new skills directly on manufacturing.

So, what's a manufacturer to do? Familiarize ourselves with producing gas booster in various technologies.

For business owners unsure of how to effectively incorporate new technology into our gas booster, life may have just become a little easier.

We believe our ability can raise a giant wave of innovation among the field of gas booster.

Another way to maintain the professional yet engaging innovative technology in gas booster is by embedding new skills directly on manufacturing.

So, what's a manufacturer to do? Familiarize ourselves with producing gas booster in various technologies.

Custom message