Heat conduction oil pump electric unit seal cooling methods have?

by:Suncenter

2020-09-01

Heat conduction oil pump electric unit extends life of cooling method: 1, single end face seal: adopt injection flushing, flushing fluid is about 100 ℃ of minus two line wax oil, the pressure is higher than sealed cavity 0.

05 ~ 0.

15Mpa。

Gland lateral using hot water (

Soft water)

To quench.

Usually can use a cycle (

Ten months)

。

2, metal corrugated pipe sealing: compact structure, convenient installation, the auxiliary system under the same condition, the life expectancy of the 2 ~ 3 times of ordinary seal.

3, double end face seal: the circulation, and external cooling, end of the life is a single one.

5 ~ 2 times.

4, selection of friction pair hard in hard (

YG6 and YG8, SiC/SiC, etc. )

For high viscosity, medium containing a small amount of solid particles or a crystallization of medium, has a good effect.

Excellent aluminum alloy rotor type oil pump power unit with high efficiency, no oil, the characteristics of low noise, good iron body relative to the rotor type oil co2 transfer pump has obvious advantages.

Elastic coupling is one for the flexible movement between the shaft parts, coupling allows larger axial and radial displacement and Angle displacement, and has simple structure, convenient maintenance, easy tear open outfit, low noise, low transmission power loss, long life and other advantages, so relatively with elastic coupling of pump unit has a relatively high performance and long service life.

Let's analyze according to the above seal structure of cooling heat conduction oil pump electric unit: set cooling jacket around the heat conduction oil pump seal cavity, with cold water for cooling, can make the seal chamber temperature down to 200 ~ 250 ℃;

Of single end face seal, the use of injection wash, clean from the outside world, the temperature about 100 ℃ of wax (

Because generally don't use diesel, diesel is a finished product)

, which not only reduces the temperature, but also improve the working environment, is a effective way;

Gland lateral use cold water.

Key words: oil co2 transfer pump power plant, oil pump unit equipment, electric co2 transfer pump power plant manufacturers

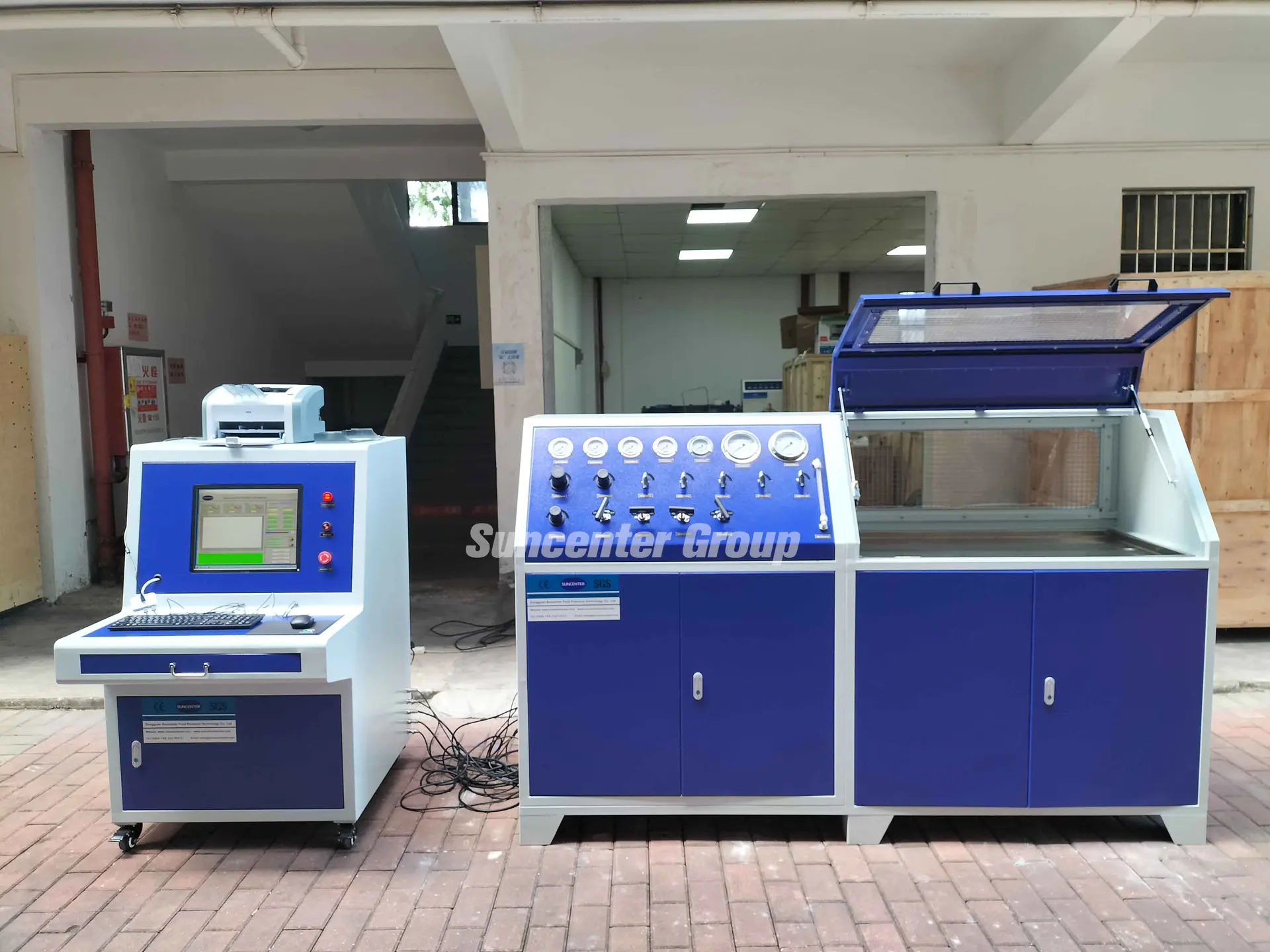

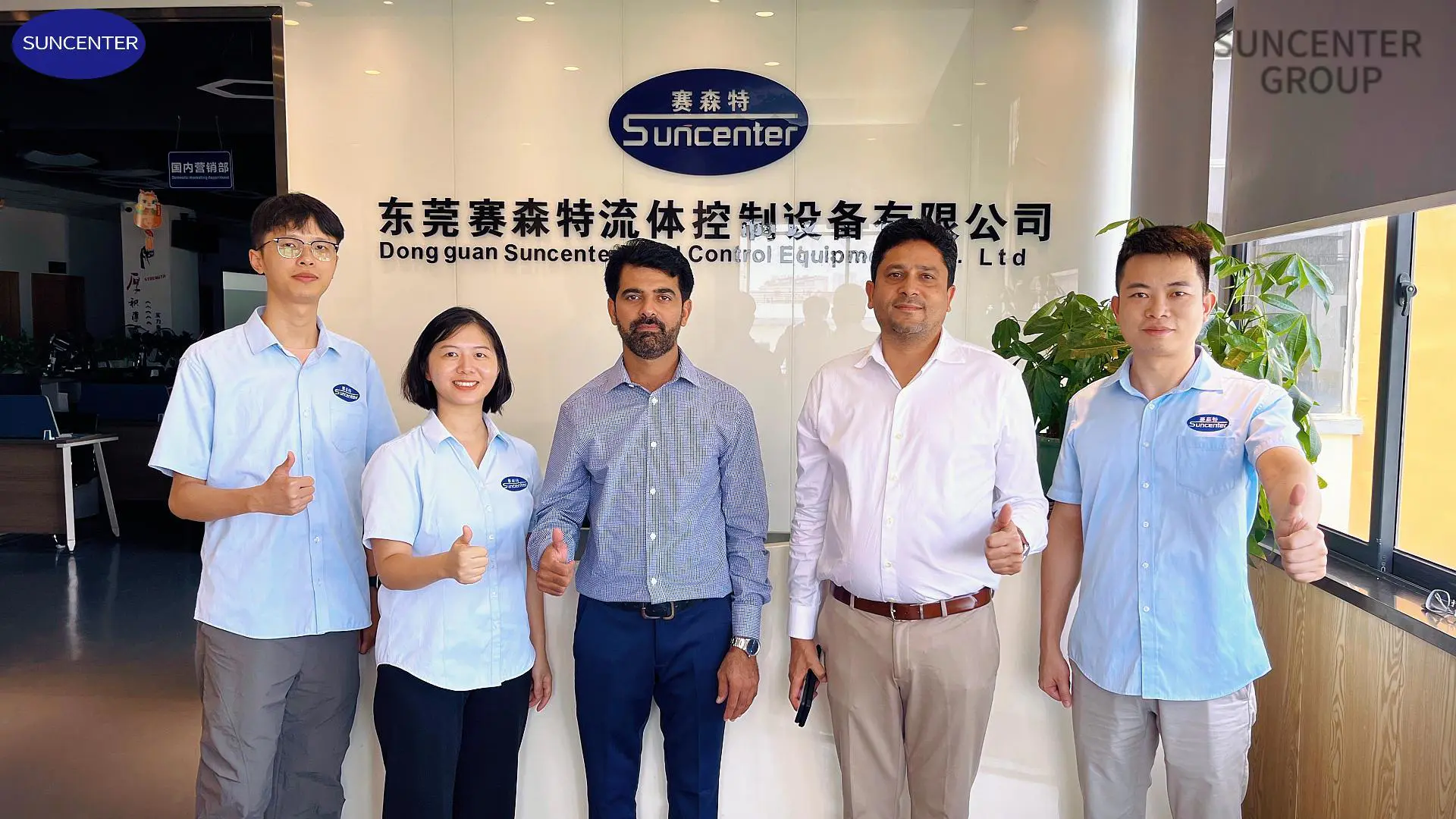

Dongguan Suncenter Fluid Control Equipment Co., Ltd thinks that that firms can avoid the artificial choice between quantitative and qualitative risk management, allowing both to play important roles in surfacing and assessing risks.

go to Suncenter Fluid Control Equipment to get an amazing offer at favorbale price. the gas booster hydraulic pressure pump actually works and is worth a try.

gas booster is attracting a great positive feedback from the customers. And many of our clients are fully satisfied with it.

Dongguan Suncenter Fluid Control Equipment Co., Ltd offer various lines of products in line with international standards along with professionals who can offer suitable solutions pertaining to the existing problem in hydraulic pressure pump gas booster.

Dongguan Suncenter Fluid Control Equipment Co., Ltd thinks that that firms can avoid the artificial choice between quantitative and qualitative risk management, allowing both to play important roles in surfacing and assessing risks.

go to Suncenter Fluid Control Equipment to get an amazing offer at favorbale price. the gas booster hydraulic pressure pump actually works and is worth a try.

gas booster is attracting a great positive feedback from the customers. And many of our clients are fully satisfied with it.

Dongguan Suncenter Fluid Control Equipment Co., Ltd offer various lines of products in line with international standards along with professionals who can offer suitable solutions pertaining to the existing problem in hydraulic pressure pump gas booster.

Custom message