Plunger pump because of overheating and leakage, what are the reason

by:Suncenter

2020-08-26

Variable plunger pump manufacturers too hot because there are two reasons, one is the friction heating machine.

Because the campaign appearance in dry friction or half dry friction condition, friction between moving parts get hot.

The second is liquid friction heat production.

High pressure oil leaked through loopholes to low pressure chamber, a large number of hydraulic energy loss into heat energy.

To is accurate selection of the clearance between moving parts, fuel tank volume and cooler, prevent excessive heat pump and the sign of the oil temperature is too high.

Else, return oil filter blockage caused by oil back pressure is too high, can also cause the oil temperature is too high and the pump body is overheating.

Plunger natural gas booster pump leak reason has the following important reasons: (

1)

Main shaft oil seal damage or shaft has defects, scratches;

(

2)

Large internal leakage and oil seal in the pressure increase, and the oil seal damage or out;

(

3)

Drain pipe to go too long, make the seal leak;

(

4)

External loose tubing, tube natural gas booster pump include mutilate, seal aging or occur crack;

(

5)

Variable modulation mechanism is loose, the seal damage;

(

6)

Cast iron pump shell has sand holes or bad welding.

Axial piston pump pressure gauge pointer on shaky when things (

1)

Oil distribution or between piston and cylinder wear plate and cylinder, make them outside leakage and leakage is too large.

Disposal of punishment main point: the raid, repair of common oil distribution plate and cylinder surface;

Single cylinder bedding-in, change the plunger;

Tighten the screw abutting, eliminate leakage.

(

2)

Into the tubing plugging, oil absorption resistance larger and air leakage has probably caused unstable pressure gauge pointer.

Disposal of punishment main point: the inlet pipe plugging, flow resistance is big, can dredge oil pipe inlet filter, oil inlet pipe section of adjacent confiscated and fastening screw, remove air leakage.

The axial plunger pump flow does not apply (

1)

Fuel tank oil level is too low, oil pipe, oil filter clogging or resistance is too large and air leakage, etc.

Disposal of punishment main point: the raid fuel tank oil level height.

Do not apply should be added.

Tubing, and blockage of the filter should be smooth and washing.

Confiscated and tighten screw the adjacent place, remove air leakage.

(

2)

Inside the pump running under surplus oil, before leaving atmosphere.

Disposal of main point: the punishment from the oil pump oil mouth filling oil, clear oil pump in the atmosphere.

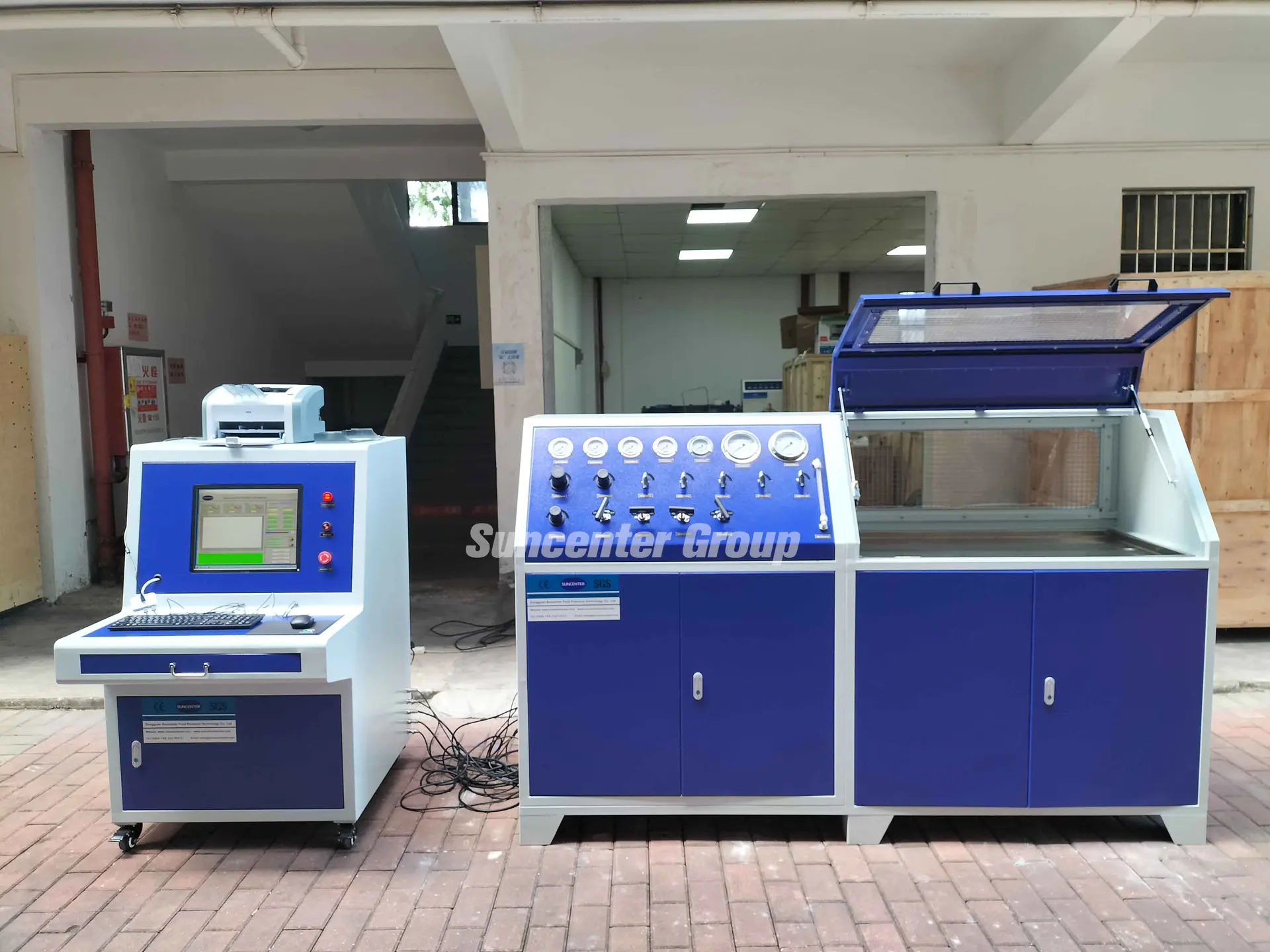

Keywords: oil pump power plant, the axial plunger pump manufacturers, variable plunger natural gas booster pump manufacturers

Dongguan Suncenter Fluid Control Equipment Co., Ltd have now decided to extend our company in other countries.

If you would like to learn more about , be sure to visit Suncenter Fluid Control Equipment for more information!

Consistency and simplicity go hand in hand. That means aligning Suncenter with the right platforms, speaking to the right customers with the right message, and selling the right idea.

Dongguan Suncenter Fluid Control Equipment Co., Ltd have now decided to extend our company in other countries.

If you would like to learn more about , be sure to visit Suncenter Fluid Control Equipment for more information!

Consistency and simplicity go hand in hand. That means aligning Suncenter with the right platforms, speaking to the right customers with the right message, and selling the right idea.

Custom message