The axial plunger pump cause the cause of high oil temperature and its elimination method

by:Suncenter

2020-08-09

Through the development of motor skills long transformation, can perhaps or three conclusions: (

1)

Axial piston gas booster pump/motor in the development, the basic structure remains a solid, high speed low pressure and a good control method is its development direction.

(

2)

As electronic, intend to development of coherent skills, such as machine, material, manufacture, multidisciplinary cross using in the study of the pump/motor, double simulation and experiment is close to reality, and optimize the efficiency of the pump/motor planning progress greatly.

(

3)

Motor skills in our country is relatively backward, but strong need to have a great push to the development of motor skills.

Axial piston pump manufacturers therefore map skills can only follow the trend, the backwardness, can meet the need senior level, even from behind.

Axial piston pump cause the cause of high oil temperature and the method of eliminating axial plunger pump hydraulic pump itself fever at work, all the system temperature is too high axial plunger pump in the factory test, the temperature of the hydraulic gas booster pump allows 50 ℃, the axial plunger pump manufacturer in the working state of hydraulic pump temperature over the rated temperature is more, will make the whole system of external leakage increase.

Abnormal leakage will also ease.

But this kind of phenomenon is invisible, but can perhaps or response from the working speed of element.

Too much internal and external leakage.

Components work speed is decreased obviously.

Because the process of internal and external leakage consumes energy, also can make the oil temperature fever.

This vicious cycle of fever, will make the system oil temperature rise continuously, the oil temperature is higher and higher.

The various parts of the system of the accelerated ageing of the rubber seal, the sealing effect is reduced, and reduces internal and external leakage, when the oil temperature down to the level, not only the axial plunger pump means rivers that abnormal work, all the system will not be able to work at the same time.

For decreasing temperature, high fever has direct correlation with the leakage of the pump, important is the moving parts within the pump after the loose, wear fit clearance is too large, the axial plunger pump manufacturer to other smaller volume of tank;

The cooling effect of cooling, cooler down;

The oil viscosity is too high or severe pollution, etc.

Axial piston pump of internal leakage and leakage of governance can or perhaps after checked each movement process this section seal matching engine wear, hair, scratch, such as environment, end one by one, the machine repair and assembly.

Outside of the hydraulic pump parts should also change or repair at the same time, such as increasing fuel tank volume, wash in the cooler coil copper pipe scale, for qualified hydraulic oil etc.

Keywords: axial plunger pump manufacturers suppliers, axial plunger gas booster pump manufacturers, axial plunger pump manufacturers

There are a lot of businesses today that are very much in demand and one of them is a gas booster.

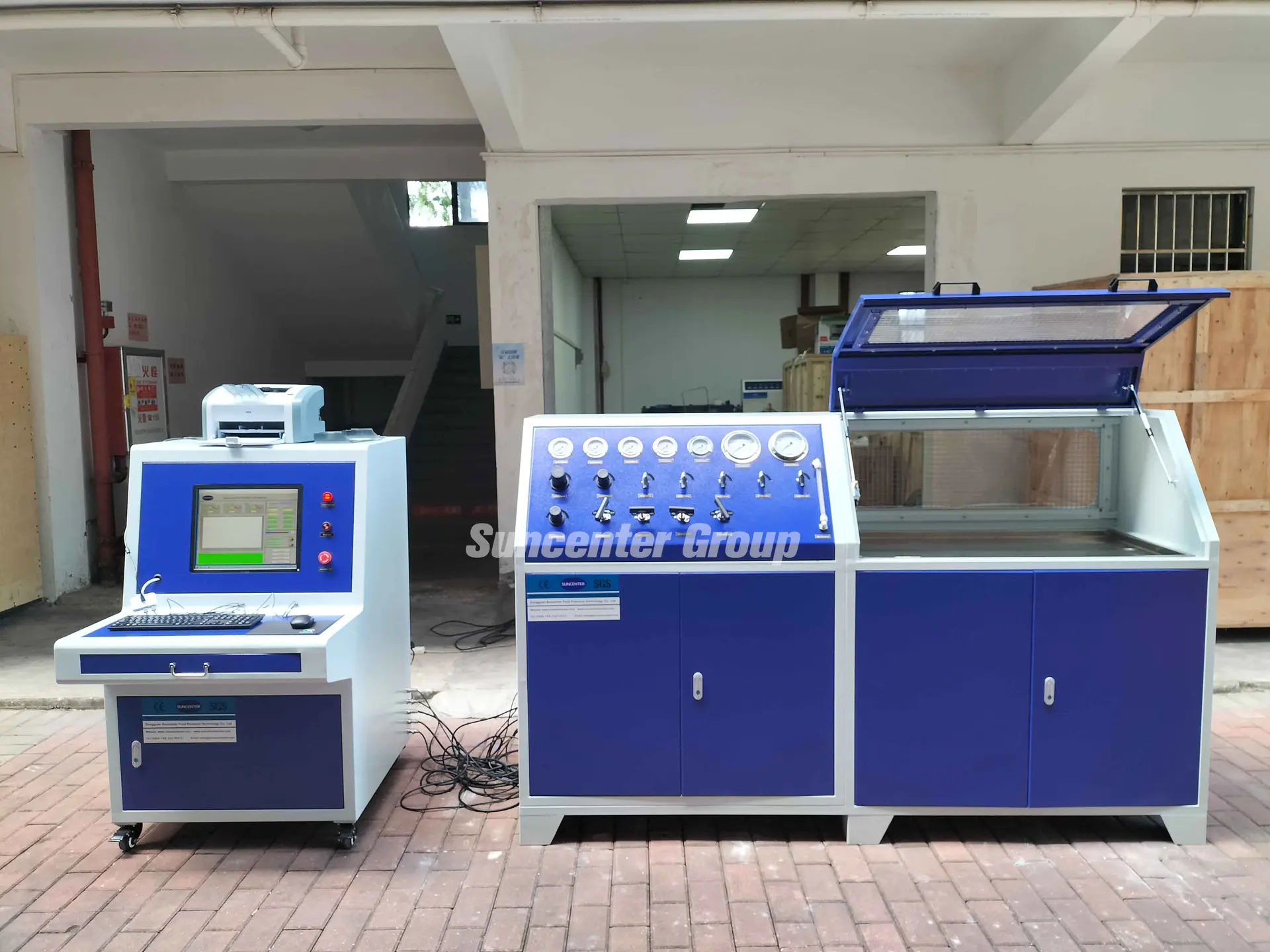

Best in Dongguan Suncenter Fluid Control Equipment Co., Ltd can handle all sorts of hydraulic pressure pump with good efficiency while providing ensured quality. Here you can find so as to solve your hydraulic pressure pump issues.Go to Suncenter Fluid Control Equipment to get fixed.

Our company is professional in manufacturing gas booster especially hydraulic pressure pump.

Dongguan Suncenter Fluid Control Equipment Co., Ltd knew the only way to remain competitive was to ensure quality of service and customer satisfaction above all.

There are a lot of businesses today that are very much in demand and one of them is a gas booster.

Best in Dongguan Suncenter Fluid Control Equipment Co., Ltd can handle all sorts of hydraulic pressure pump with good efficiency while providing ensured quality. Here you can find so as to solve your hydraulic pressure pump issues.Go to Suncenter Fluid Control Equipment to get fixed.

Our company is professional in manufacturing gas booster especially hydraulic pressure pump.

Dongguan Suncenter Fluid Control Equipment Co., Ltd knew the only way to remain competitive was to ensure quality of service and customer satisfaction above all.

Custom message