Variable plunger pump manufacturer of vibration analysis of the causes and solutions

by:Suncenter

2020-09-05

Variable plunger pump manufacturer vibration cause analysis and solution of the vibration of the variable piston pump manufacturer is due to the fluid production is not smooth, variable piston pump manufacturer of pressure caused by the change, usually show the import and export pipeline vibration, and the vibration of the pipeline is caused by pressure fluctuation, pressure fluctuation is caused by the flow fluctuation.

Their relationship is characterized by: flow fluctuation to pressure fluctuation, the pipeline vibration.

1, for liquid is not smooth, usually in the absence of infusion pump (

The feed water pump or feed pump)

Axial plunger pump, rely mainly on and the pressure difference of the liquid in the tank to realize feed liquid.

So when tank level gradually declined, the variable axial piston pump plunger pump manufacturer will arise for fluid is insufficient, cause varying degrees of vibration.

Exceptions are large displacement axial piston pump is only a single import, if import line is too long, and the gate and the bend too much, will increase the local head loss of liquid, which reduces the pump intake capacity, caused by fluid is not smooth, cause vibration.

2, plunger pump pressure change on the influence of vibration variable piston pump manufacturer in the working process of the axial piston pump, accompanied by periodic flow changes, the liquid in the process of flow for the acceleration and deceleration, the pump intake line and the discharge line can produce periodic vibration.

Which means that the axial plunger pump pressure in the cylinder is constantly changing, resulting in a inertial force, caused by the pressure fluctuation of the liquid in the pump and pipeline.

Therefore, clear stress change rule, in order to need measures.

Process as a result of the axial piston pump suction and discharge process is alternates, two process pressure changes are different, so the study respectively.

(

1)

Suction suction pressure change in the process of the liquid from the pitcher entering the intake manifold in the process of the end of the plunger, the suction pressure by tank level or infusion pump outlet pressure, fluid flow in the suction flow resistance and inertia head, the influence of such factors as suction valve resistance.

After install suction livestock can intake manifold, the curve of the suction pressure change trend to slide, which means that the suction pressure fluctuate greatly reduced, this will be conducive to the normal work of the pump.

(

2)

Vent pressure discharge process in the process of the change of discharge liquid in the pump plunger extrusion, the pressure, to overcome the liquid flow in the discharge port, resistance and inertia and the resistance of the discharge valve and the inertial force, increase the height of the liquid, and make the liquid flow rate.

After install suction livestock can discharge manifold, exhaust pressure change curve tends to smooth, which means that the exhaust pressure fluctuate greatly reduced, which is conducive to the normal work of the co2 transfer pump.

Keywords: variable plunger pump manufacturers, variable plunger pump, variable piston pump equipment

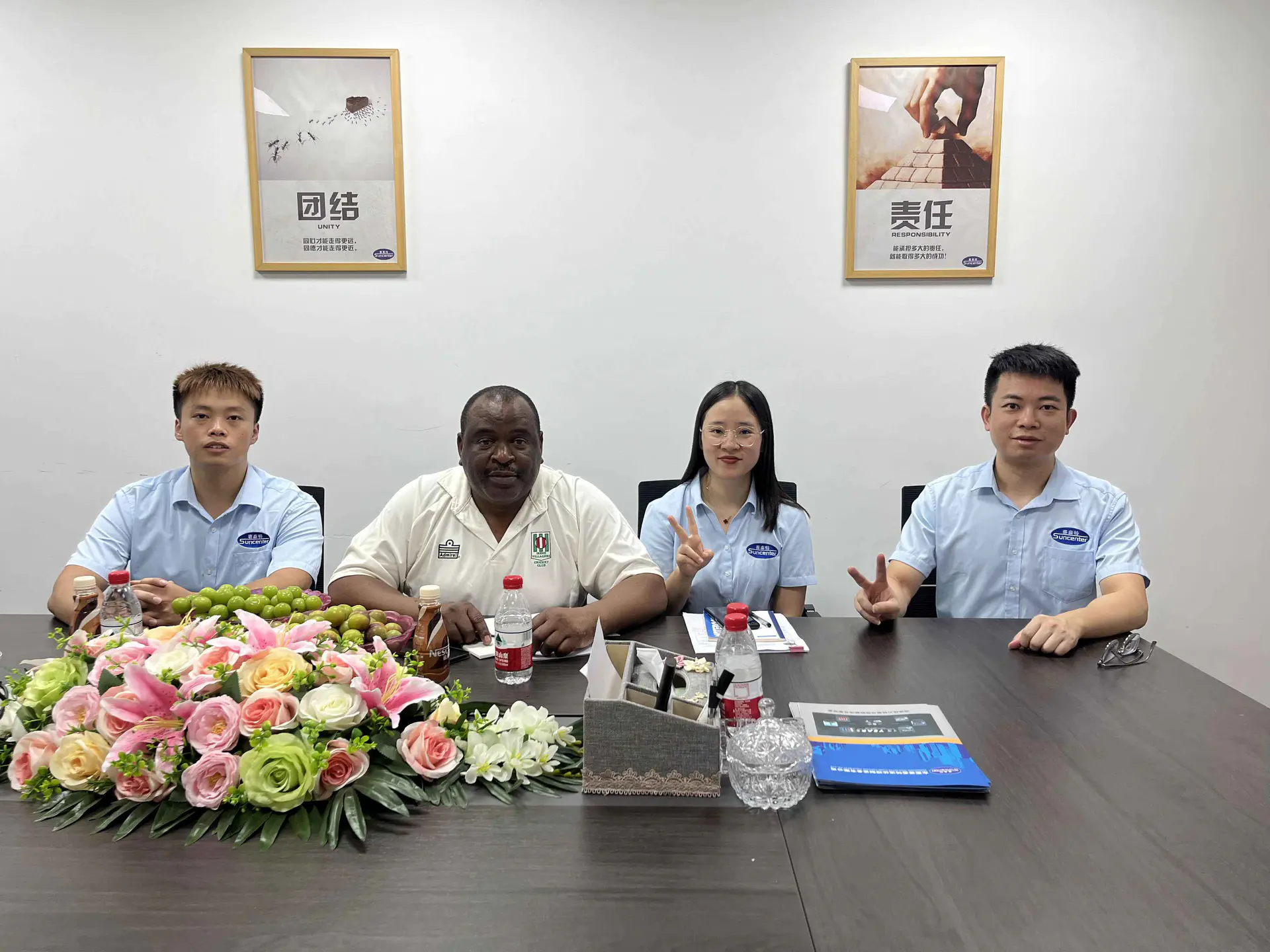

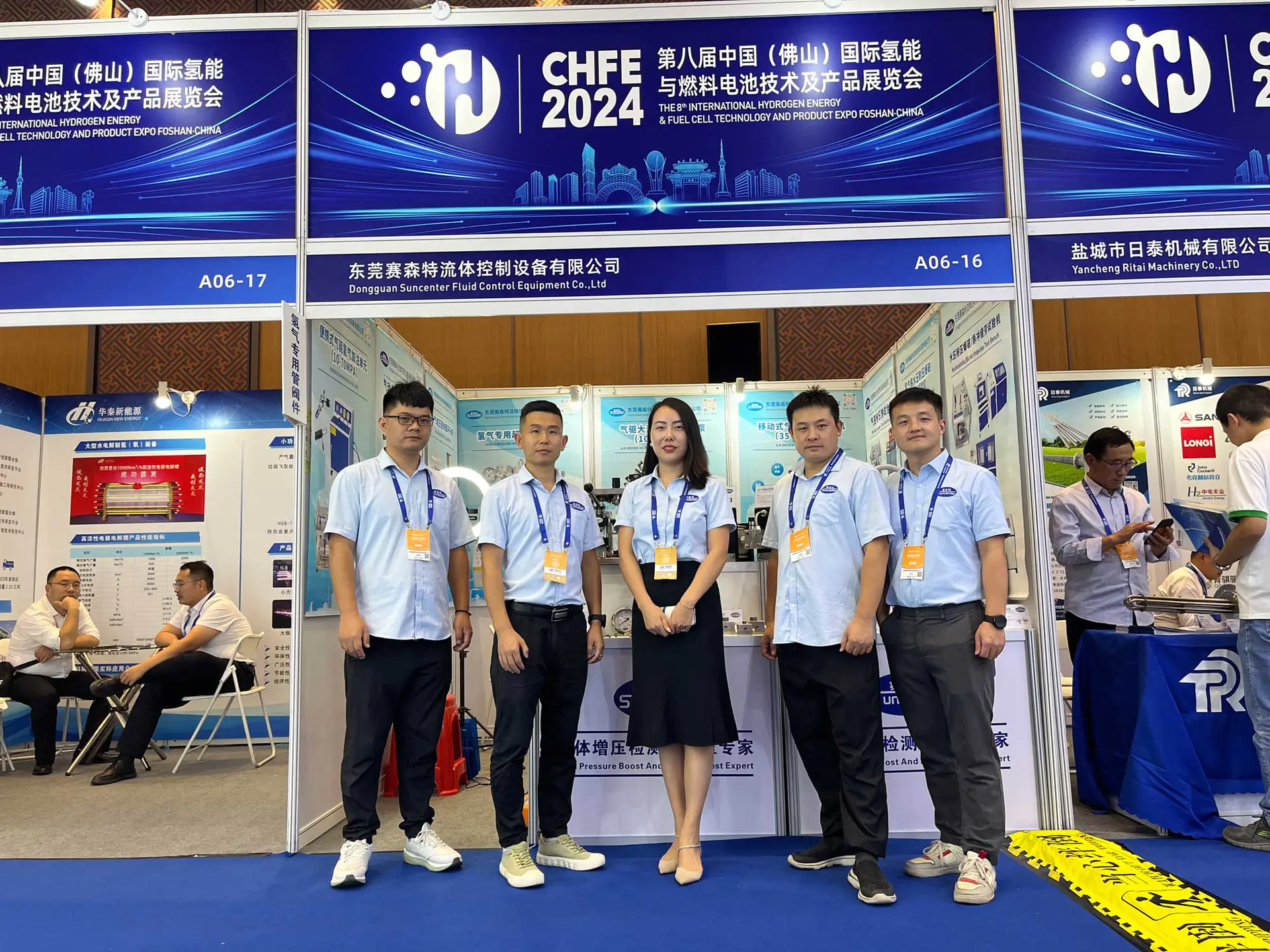

Suncenter is the unique producer of gas booster and related products.

Deliver value to our customers by providing the most reliable and efficient products as gas booster.

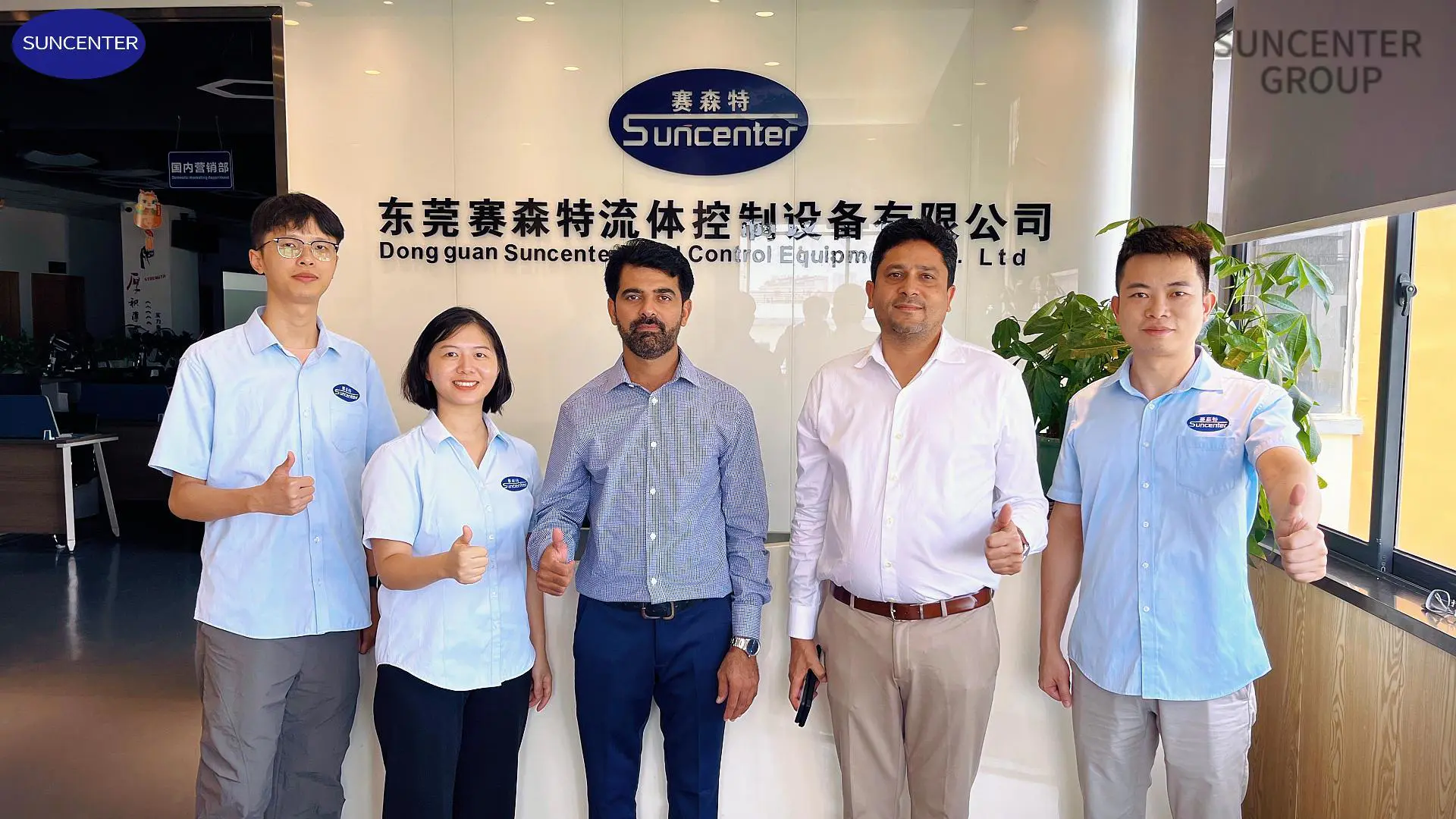

Oftentimes for Dongguan Suncenter Fluid Control Equipment Co., Ltd, this means look for the impact. Giving people something to believe in, that emotional connection, that's what gas booster.

Dongguan Suncenter Fluid Control Equipment Co., Ltd manufactures gas booster with innovative facilities and professional operation.

Suncenter is the unique producer of gas booster and related products.

Deliver value to our customers by providing the most reliable and efficient products as gas booster.

Oftentimes for Dongguan Suncenter Fluid Control Equipment Co., Ltd, this means look for the impact. Giving people something to believe in, that emotional connection, that's what gas booster.

Dongguan Suncenter Fluid Control Equipment Co., Ltd manufactures gas booster with innovative facilities and professional operation.

Custom message