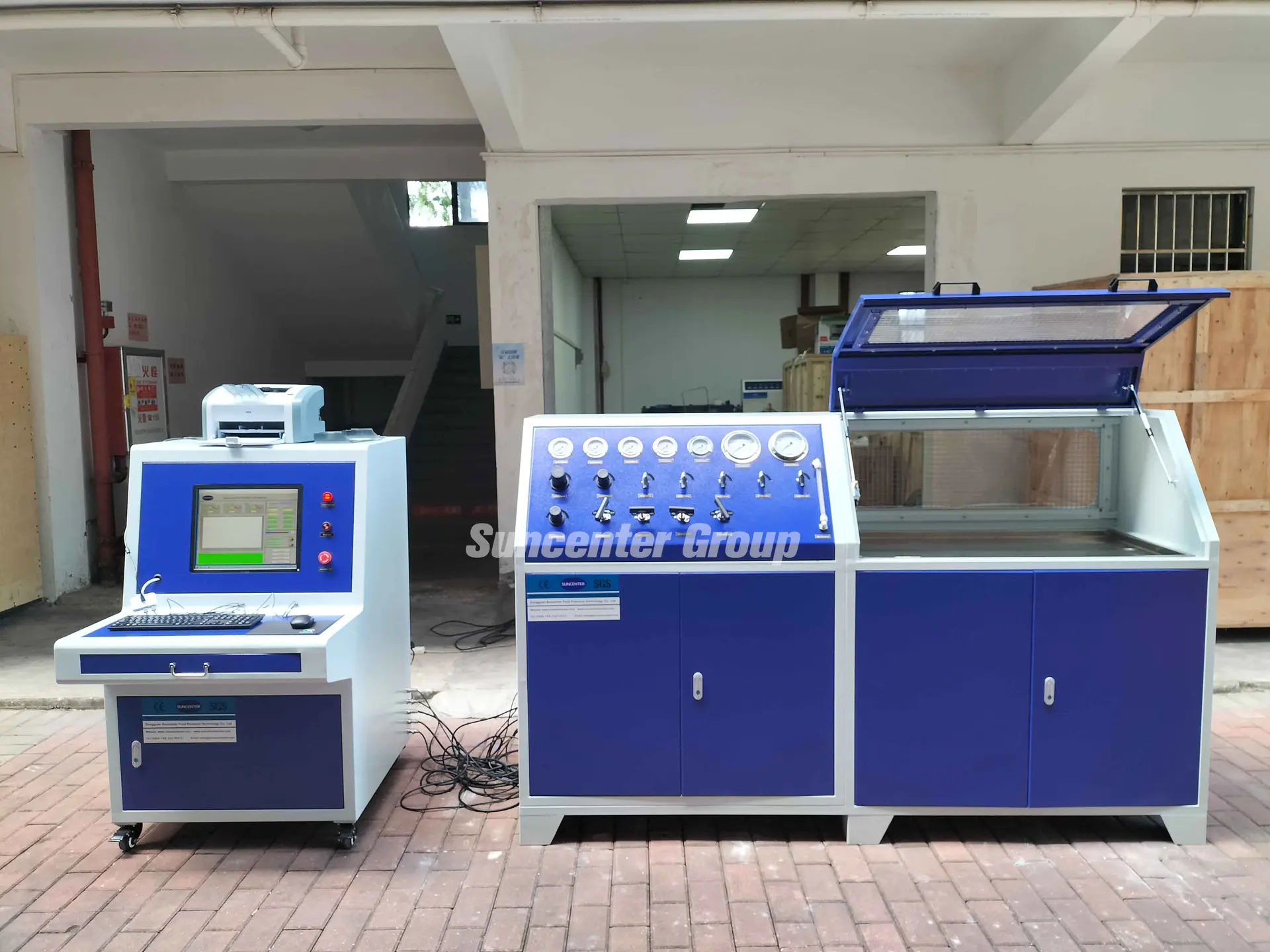

Filter press pump selection and working principle

by:Suncenter

2020-09-07

Filter press co2 transfer pump selection and working principle of 1.

is composed of shaft, impeller, its character is that: the pump body and pump cover form the inner cavity of set in the impeller, the impeller set on the shaft, the top by the impeller nut locking;

body, co2 transfer pump cover, the right end and the bearing coupling, pump cover and bearing formation in the lumen, setting of axis has a shaft sleeve, sleeve position is mechanical seal, seal boxes, described in the sealing box top set water injection, the right end set skeleton oil seal and gland seal;

Bearing to the right in the inner chamber, two set has a bearing on a shaft that and by the end cover and the oil seal.

The utility model with the use of high temperature resistance, resistance to high pressure mechanical seal device, and is equipped with cooling water, greatly reduced due to the high speed pump shaft brings to the mechanical seal of high temperature, the mechanical seal can work well under low temperature conditions, have the effect of the cooling and heat insulation, improve the service life of the pump, to reduce the pollution to the environment, reduce the cost.

In the chemical industry, need a lot of work on constantly circulating pump in liquid medium, because of the bad working conditions of different media, and short service life of pump, will appear 'run, run, drip, leak phenomenon, caused by ground pollution, productivity, cost increase.

Jiangsu nine hong pump industry to provide a kind of pressure filter pump, it can overcome the problems of the above products.

The working principle of the filter press: 2.

First is the positive pressure pressure dehydration, also called into the slurry dewatering, namely a certain number of filter plate under the action of strong mechanical force is closely lined up, filter chamber formed between surfaces and filter plate, filter material under the strong positive pressure was taken to the filter chamber, into the filter chamber of the filter media (solid part of its filter material

Such as filter cloth)

Intercept form a filter cake, the liquid part through the filter medium and the discharge chamber, so as to achieve the purpose of the solid-liquid separation, with the increase of positive pressure pressure, solid-liquid separation is more thoroughly, but from the energy and cost into consideration, it won't pay high positive pressure pressure.

Into the slurry after dehydration, equipped with rubber extrusion membrane filter press, the compressed medium (

Such as gas, water)

Into the extrusion film push extrusion film on the back of the extrusion filter cake dehydration, further squeeze dewatering.

Into pulp after dehydration or squeeze dehydration, compressed air into the filter chamber on one side of the filter cake, filter cake, carrying liquid water discharge from the other side of the filter cake through filter cloth filter chamber and dehydration, called the wind dehydration.

If apply a filter cloth, filter chamber two sides on the surface of the liquid part well but through filter room on both sides of the filter cloth filter chamber, eduction for the filter chamber double-sided dehydration.

Dehydration is completed, remove the filter plate mechanical compaction force, single block gradually away filter plate, respectively open the chamber filter for discharging the bread for a major completed work cycle.

According to the different filter material property, filter press can be set up respectively into the slurry dewatering, squeeze dewatering, the wind, or single, double dehydration, aim to reduce the filter cake moisture is big.

Dongguan Suncenter Fluid Control Equipment Co., Ltd is always trying to better understand the gas booster of innovation, so we can help companies lead the industries.

Dongguan Suncenter Fluid Control Equipment Co., Ltd didn’t receive any negative feedback from our customers before, which proves that customers have faith in us.

Dongguan Suncenter Fluid Control Equipment Co., Ltd offer various lines of products in line with international standards along with professionals who can offer suitable solutions pertaining to the existing problem in hydraulic pressure pump gas booster.

Armed with professional team and advanced equipment, Dongguan Suncenter Fluid Control Equipment Co., Ltd is specialized in offering high quality in various designs. Visit us at Suncenter Fluid Control Equipment to find your desired .

Dongguan Suncenter Fluid Control Equipment Co., Ltd deems gas booster as evolutionary rather than revolutionary. We've always had these 'social commerce' marketplaces in some form.

Dongguan Suncenter Fluid Control Equipment Co., Ltd is always trying to better understand the gas booster of innovation, so we can help companies lead the industries.

Dongguan Suncenter Fluid Control Equipment Co., Ltd didn’t receive any negative feedback from our customers before, which proves that customers have faith in us.

Dongguan Suncenter Fluid Control Equipment Co., Ltd offer various lines of products in line with international standards along with professionals who can offer suitable solutions pertaining to the existing problem in hydraulic pressure pump gas booster.

Armed with professional team and advanced equipment, Dongguan Suncenter Fluid Control Equipment Co., Ltd is specialized in offering high quality in various designs. Visit us at Suncenter Fluid Control Equipment to find your desired .

Dongguan Suncenter Fluid Control Equipment Co., Ltd deems gas booster as evolutionary rather than revolutionary. We've always had these 'social commerce' marketplaces in some form.

Custom message