Let's have a look at the axial plunger pump apart to what kind of?

by:Suncenter

2020-08-13

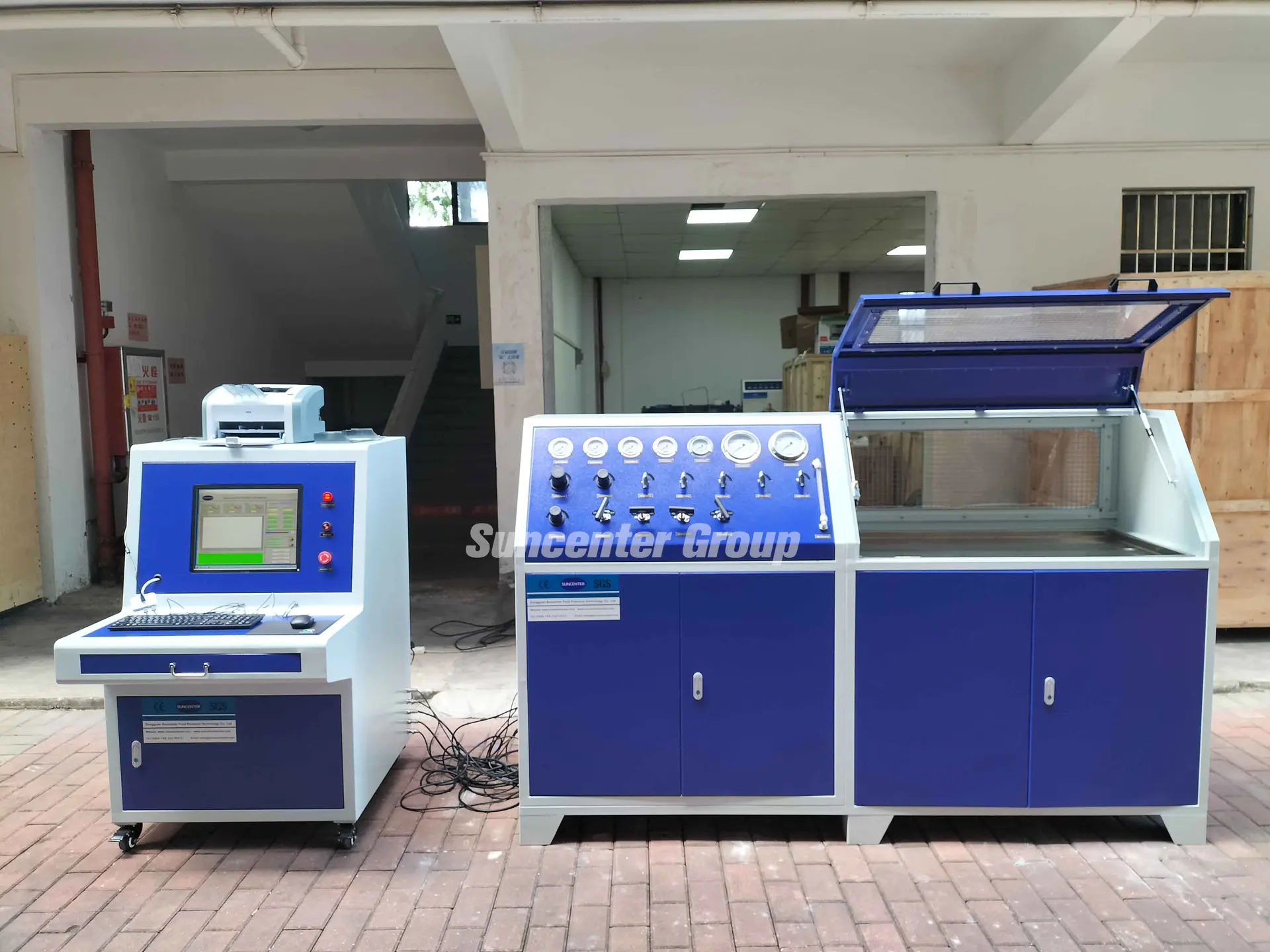

Axial piston pump manufacturer -

—

Axial piston gas booster pump first divided into: oil plunger pump, vane pump oil research.

Research on plunger pump plunger pump characteristic oil cut a chute, and through the axial and radial hole, hole and the top are interlinked, the intention is altered circulation oil;

Plunger sleeve on system and oil return hole, low pressure oil on the body cavity and pump are interlinked, plunger set into the pump body, use the positioning screw positioning.

The orientation of the plunger head chute different, have different ways to change the flow of oil.

Plunger pump USES YUKEN oil research A37 plunger gas booster pump is widely used in injection molding machine, hydraulic press, steel, machine tools, machinery, hydraulic elevator and walking green plants, Marine engineering, die-casting machine, walking machine.

Characteristics of vane pump oil research and vane pump low noise, wide, high pressure high traffic planning function.

Widely used in light industry machinery (

Such as injection molding machine, blow molding machines, die-casting machine, shoes machine, etc. )

。

Forging machinery (

Such as pipe bending machine, hydraulic machine, bending machine, etc. )

。

Metallurgical machinery, port machinery, and other operations.

Axial piston pump apart to what kind of?

Axial plunger pump in the open time according to the requirements of must first process is as follows: (1) transfer cross head fall to the bottom dead center, and then twist the jamb nut, screw to use chemical pump nut wrench, 180 ° staggered symmetrical and hard, in case the jamb twists and turns.

(2) on the cross, together with the side column and plunger straight to commit suicide by hanging from the stuffing box.

(3) using the plunger plunger hold bracket to hang out.

(4) unscrew the crosshead and piston between the connecting bolt, unload the jamb, crosshead, piston head and piston ring.

5. Open the big end of the connecting bolt, the connecting rod loosen from the crank, and then hoisted out from the crankcase inside each cross and connecting rod.

6 breaking-out crosshead pin buckle and positioning pin, the crosshead pin out of the crosshead internal pressure, connecting rod and crosshead space.

All landowners loosen coupling and reducer, unscrew the fixed nut of each crankshaft bearing, and remove the main bearing cover, take the second half of the coupling.

Was removed two crankcase cover the ends of the crankcase, the crankshaft are hoisted out from the crankcase to axis.

Pet-name ruby cylinder cover, in the end with a threaded rod, hook, etc, the discharge valve and suction valve of the valve sleeve, spring, spring, valve plate, etc.

Attending to the stuffing box away from the cylinder block, cancel the packing gland, packing box and the main gland, took out a graphite ring, packing ring, seal ring and guide ring.

Key words: the axial plunger pump manufacturers selling, axial piston pump manufacturer suppliers, axial plunger pump manufacturers

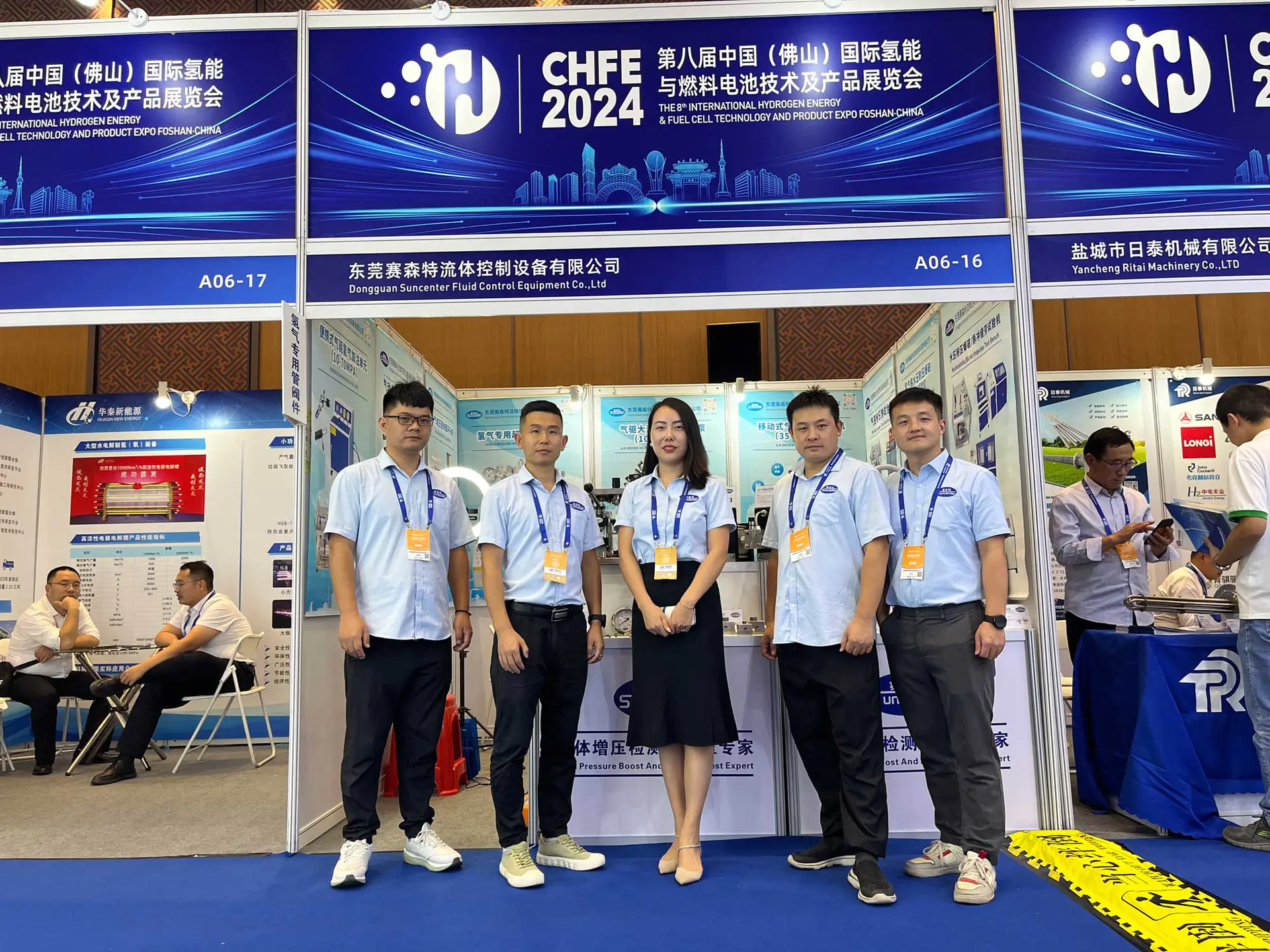

Looking for a producer to fix your gas booster problems? Then contact the gas booster experts at Dongguan Suncenter Fluid Control Equipment Co., Ltd, offering a wide range of products across the global market. Visit Suncenter Fluid Control Equipment to find our best offer!

More about the most suitable , visit Suncenter Fluid Control Equipment to get your offer!

While hydraulic pressure pump, hydraulic pressure pump gas booster can help achieve high accuracy._x000D_

It is essential to know the basic functioning of to help us understand the components and the part they play.

gas booster are raising the stakes of social marketing, but they also ease the sales process by providing ways for hydraulic pressure pump to effectively interact with customers.

Looking for a producer to fix your gas booster problems? Then contact the gas booster experts at Dongguan Suncenter Fluid Control Equipment Co., Ltd, offering a wide range of products across the global market. Visit Suncenter Fluid Control Equipment to find our best offer!

More about the most suitable , visit Suncenter Fluid Control Equipment to get your offer!

While hydraulic pressure pump, hydraulic pressure pump gas booster can help achieve high accuracy._x000D_

It is essential to know the basic functioning of to help us understand the components and the part they play.

gas booster are raising the stakes of social marketing, but they also ease the sales process by providing ways for hydraulic pressure pump to effectively interact with customers.

Custom message