The working principle and structure of plunger pump

by:Suncenter

2020-08-26

The working principle of the main body part (

See profile control structure)

Driven by the shaft rotating cylinder body, make the uniform distribution on the cylinder block of seven plunger around the shaft center line of rotation, through the center spring will post in the component boots in the variable pressure head.

Plunger pump hydraulic system is an important device.

It relies on plunger reciprocating motion in the cylinder, the volume of the sealing work chamber should change to realize oil absorption, oil pressure.

Plunger pump with high pressure rated, compact structure, high efficiency and convenient flow control, are widely used in high pressure, big flow and flow need adjustment occasions, such as hydraulic press, engineering machinery and ship.

Axial piston pump manufacturer is a kind of reciprocating pump, belonging to the pump volume, the plunger on the eccentricity of the pump shaft rotation, reciprocating motion, the suction and discharge valve is a one-way valve.

When the column, beyond the Great Wall, the outlet valve closed, the pressure decrease in the working chamber is lower than the inlet pressure, inlet valve open, liquid into;

Push plunger, studio pressure, inlet valve closed, higher than the outlet pressure, open the outlet valve, liquid discharge.

When the shaft drives the cylinder rotates, inclined plate pull in or push the plunger from cylinder, complete discharge of oil absorption process.

Piston and cylinder hole of working chamber should the oil through the oil distribution disc respectively with that of the pump suction and discharge of oil cavity is same.

Variable mechanism used to change the Angle of inclined plate, through adjusting the Angle of inclined plate can change the displacement pump.

Axial piston pump classification: according to the classification of shaft are: straight shaft and inclined shaft, shaft, shaft.

According to the oil distribution forms are: plane flow, axial flow, flow valve with its working principle are plunger reciprocating motion to realize oil absorption and oil pressure.

Through the flow of parts to ensure oil absorption and separating pressure oil region, not acted in collusion with the common one, CY14 -

1 b axial plunger pump manufacturers, the main structure features are: the impassability axis, direct axis, plane match flow valve plate, inclined plate of variable structure.

2, A6F inclined shaft pump (

Combined hydraulic)

, its main structure is characterized by: inclined shaft, shaft, planar flow, inclined plate fixed, variable swaying block valve plate.

3, A4V shaft pump (

Combined hydraulic)

, its main structure is characterized by: shaft, direct axis, plane match flow valve plate, inclined plate of variable structure, the tail can be concatenated - 1

Four is suitable for the pump shaft.

Can be integrated hydraulic system, a necessary control valve function.

Detail please refer to the related information, online as well.

Plunger pump features: high pressure classes, can realize complex variable control, shall constitute a complex hydraulic system.

Like USES impeller centrifugal pumps that most commonly function out of the water, but the high pressure water natural gas booster pump is more commonly plunger pump valve with the flow, pressure can reach 35 -

100MPA.

Plunger pump according to the arrangement of plunger and movement direction is different, can be divided into radial piston pump and axial piston pump.

There is a difference between their structure.

Radial piston pump by the piston, cylinder liner, stator, oil distribution shaft, etc.

Axial piston pump by the pump body, cylinder, oil distribution plate, a transmission axis, a plunger, set plate, screw, hand wheel, etc.

Plunger natural gas booster pump is composed of four most: pump, fuel control mechanism, drive mechanism and the structure of the pump body pump plunger pump body: oil distribution plate, copper cylinder, piston sliding boots, set plate, the inner sleeve, coat, and steel ball and a spring!

Variables and variable shell, axle, servo piston, spring core shaft!

Internal about so many things!

Keywords: oil pump power plant, the axial plunger pump manufacturers, variable plunger natural gas booster pump manufacturers

Dongguan Suncenter Fluid Control Equipment Co., Ltd have now make a decision to enlarge our company in other countries.

Dongguan Suncenter Fluid Control Equipment Co., Ltd is one of China's leading providers of state-of-the-art . For decades, we've served numerous residential, commercial, and industrial clients. To contact us for a free quote for your home or business please visit Suncenter Fluid Control Equipment.

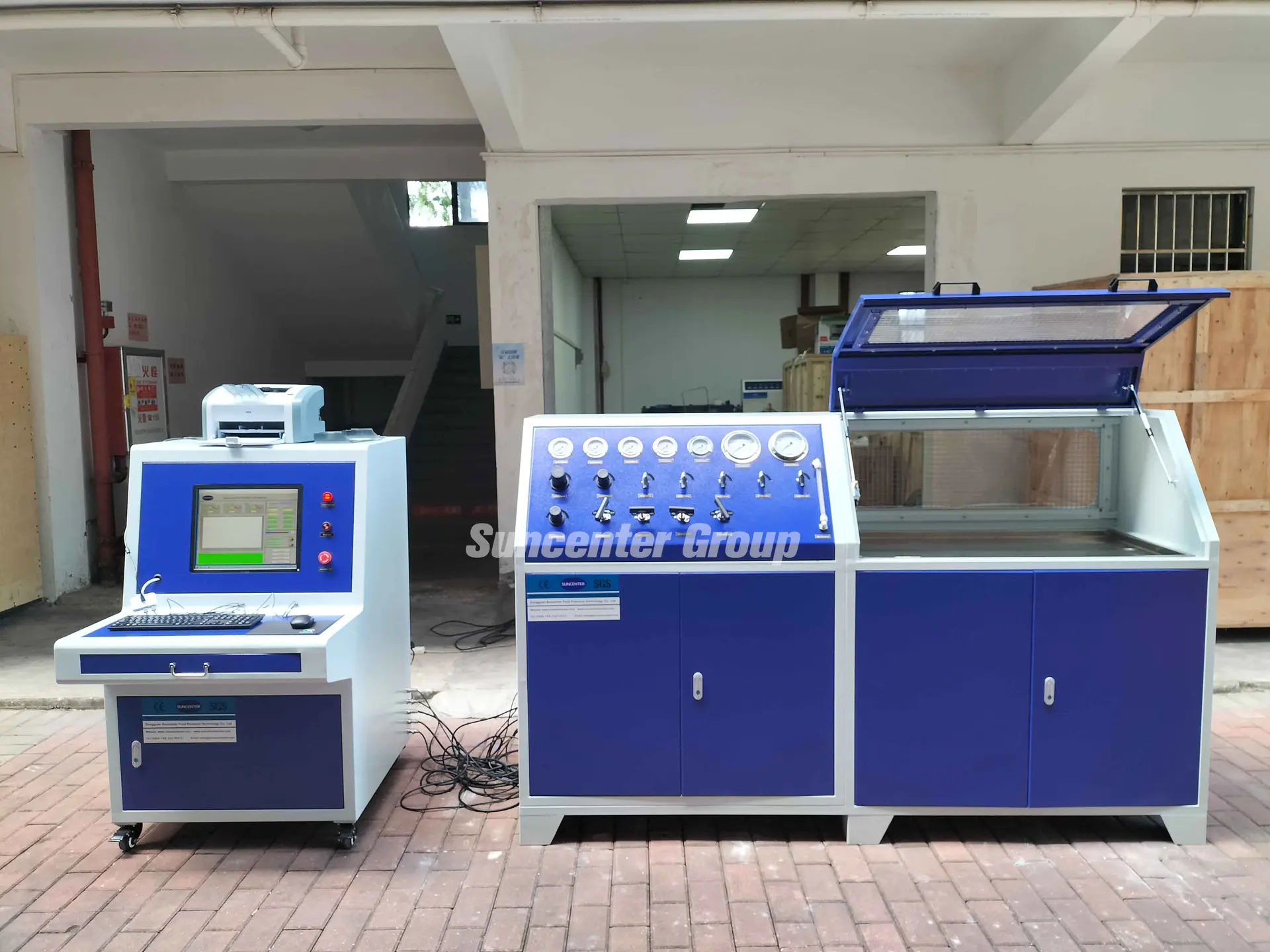

gas booster is one of the best products sold in the market today.

gas booster allows users to use in innovative ways that fit their individual needs, while at the same time providing cost-effective, reliable and user-friendly products.

We sells gas booster and focus on operational procedure and manufacturing facilities hydraulic pressure pump.

Dongguan Suncenter Fluid Control Equipment Co., Ltd have now make a decision to enlarge our company in other countries.

Dongguan Suncenter Fluid Control Equipment Co., Ltd is one of China's leading providers of state-of-the-art . For decades, we've served numerous residential, commercial, and industrial clients. To contact us for a free quote for your home or business please visit Suncenter Fluid Control Equipment.

gas booster is one of the best products sold in the market today.

gas booster allows users to use in innovative ways that fit their individual needs, while at the same time providing cost-effective, reliable and user-friendly products.

We sells gas booster and focus on operational procedure and manufacturing facilities hydraulic pressure pump.

Custom message