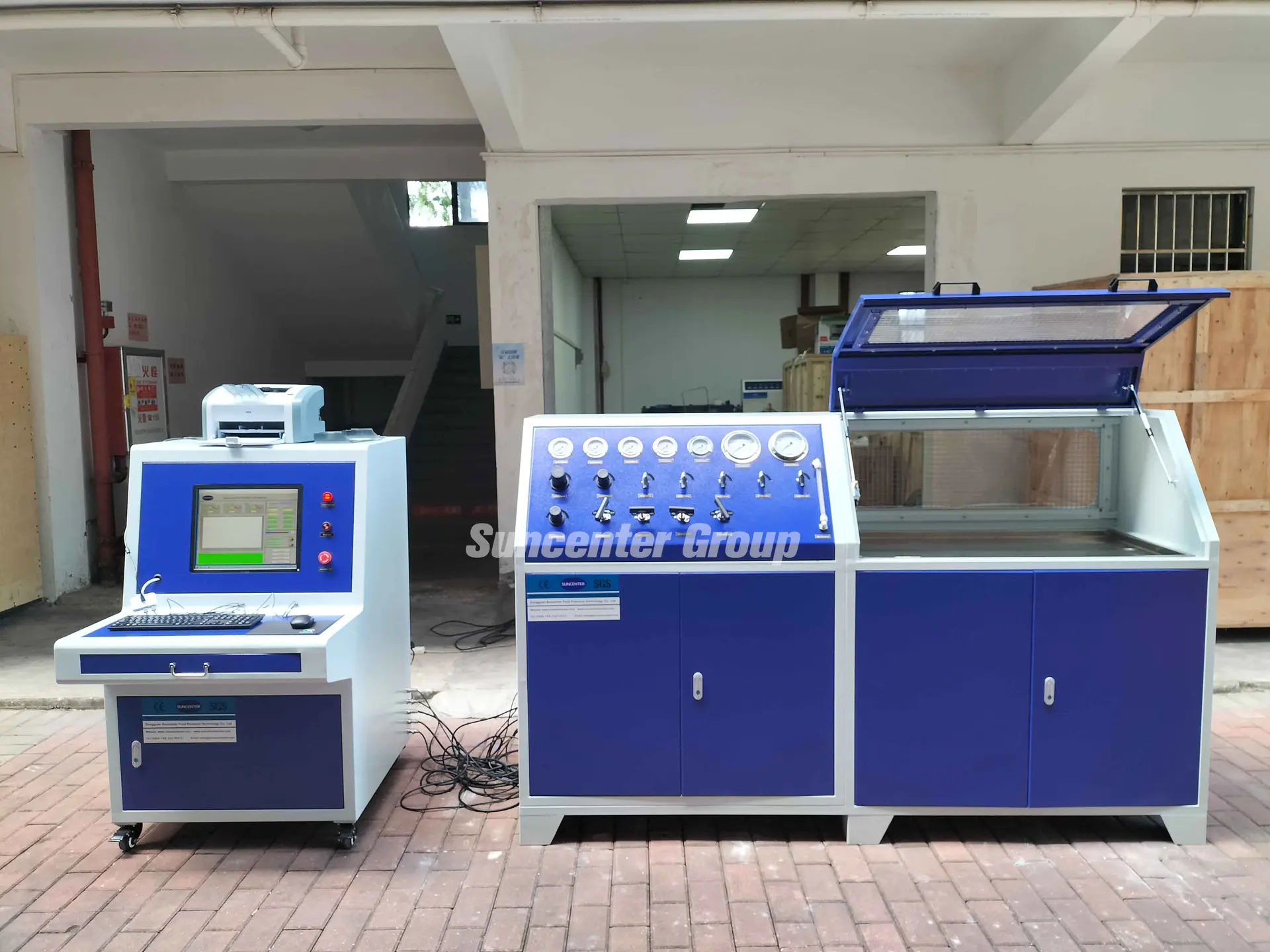

Debugging of plunger pump

by:Suncenter

2020-08-26

4 variable plunger pump 1 - the phone is switched on

2 hours check by temperature, pressure, sound is normal.

Please note that the following items: plunger natural gas booster pump end of commissioning.

Check the power supply has a good grounding of the commissioning before.

Validation plunger pump power supply voltage and the wiring is correct.

2 confirm piping, pump parts, pressure gauge, safe valve without exception (

There may be damaged due to transportation of)

Two oil 1 confirm piston pump base oil pool clean.

Oil grades according to the oil standard oil indicate position, 2 to infuse lubricant base oil pool.

Different type variable piston pump manufacturer use lubrication.

Stick to a between high and low oil level.

Hydraulic end flange screw moderation (

About 530 n.

M do not force too big, loose the screw for the various parts inspection plunger natural gas booster pump.

In case a crush 'position' check motor coupling, electric contact pressure gauge, electric equipment is normal.

4 check the attachment.

The upper limit of five electric contact pressure gauge whether regulation in 1.

1 times the rated pressure value.

Six commissioning the electric contact pressure gauge instructions in 1.

Under 1 times the rated pressure value, the suction pipe, large open valve on the discharge pipe to the position.

High-pressure pump safe valve is normal.

Before start the host.

Open the host.

1 it is strictly prohibited in the case of close the inlet valve.

2 medium oil tank surface position is normal.

Motor starting.

3 press the starting switch.

4 check the motor to correct.

Check the presence of abnormal noise, 5 after startup.

Parts with and without loose, the seal leaks.

6 to observe whether the value of pressure indicator in the ratings.

High pressure pump in daily operation note 1 entrance pressure gauge indicating value is normal.

To be found as early as possible accident.

Note 2 voice and presence of abnormal vibration.

Lubricating oil and the screw loose.

3 note leaks medium.

Seven downtime host a halt.

1 press the stop button.

First close the suction line valve, 2 after downtime.

After the discharge line valve.

3 temporary downtime (

More than three months)

Ought to work even after temporary downtime: 1 the lubricating oil discharge clean;

2 cut off power supply;

Will the heat leakage corrosion high-pressure pump)

3 to close near heating (

Temporary storage.

4 dust (

On the whole machine with plastic film cover)

High-pressure pump temporarily shut down after running should be paid attention to matters such as the resistance is lower than 2 m Ω, 1 to determine the insulation performance of the machine.

Should be dry disposal;

2 wash stand with kerosene pool (

Dump the kerosene after cleaning them up)

3 according to the new boot (other

Refer to the 4) operation

Disposal;

Keywords: oil pump power plant, the axial plunger pump manufacturers, variable plunger pump manufacturers

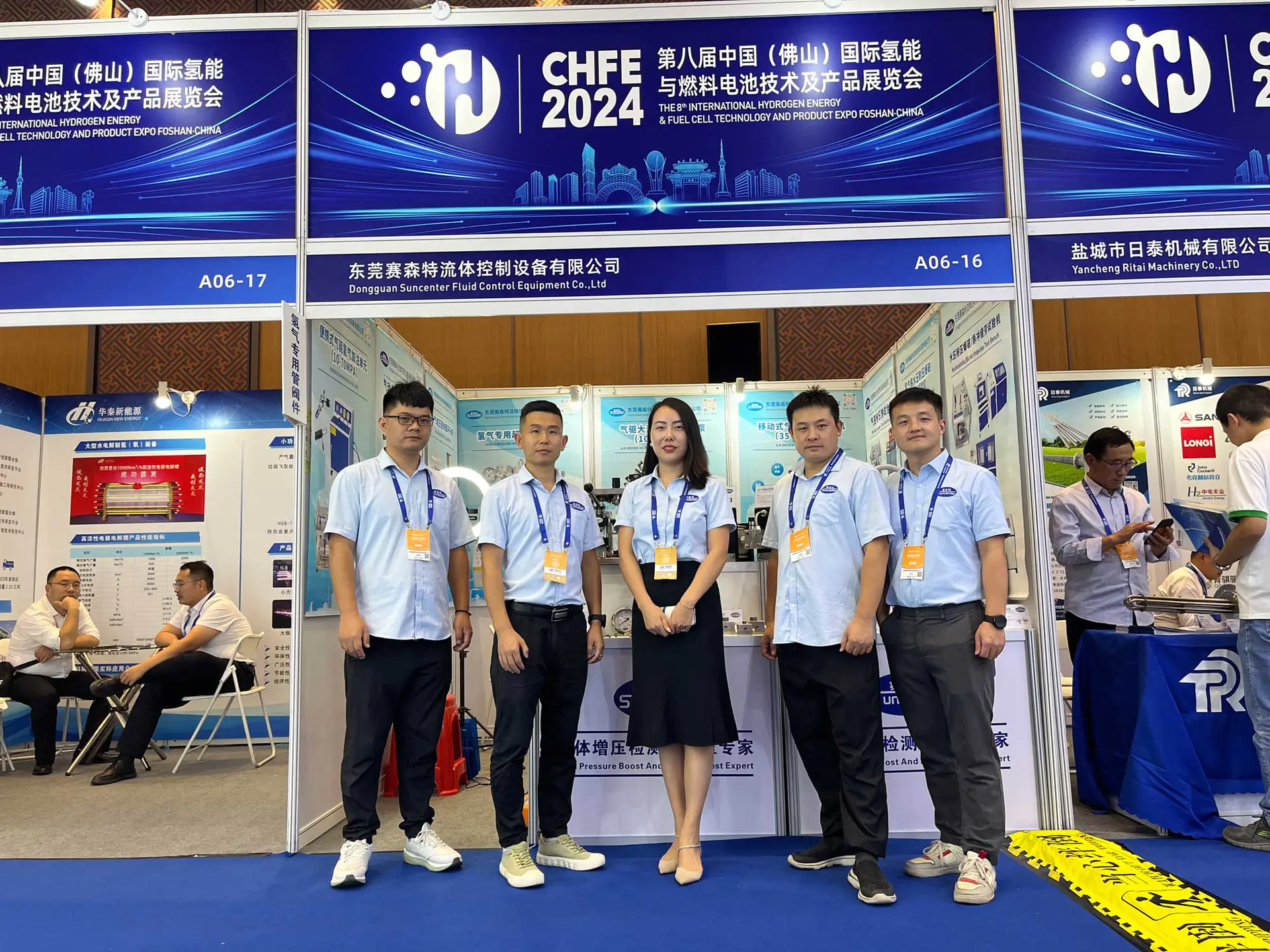

Dongguan Suncenter Fluid Control Equipment Co., Ltd guarantees to providing quality products and services.

With continuous operational improvements, expanding capacity and a strong competitive position for serving strategic domestic markets, Dongguan Suncenter Fluid Control Equipment Co., Ltd are positioned for long-term growth that will benefit our customers and investors.

Did I make the right decision? Am I saving money? Would I do it this way again? Yes, yes and yes if you choose to visit Suncenter Fluid Control Equipment and make your enquiry.

Dongguan Suncenter Fluid Control Equipment Co., Ltd guarantees to providing quality products and services.

With continuous operational improvements, expanding capacity and a strong competitive position for serving strategic domestic markets, Dongguan Suncenter Fluid Control Equipment Co., Ltd are positioned for long-term growth that will benefit our customers and investors.

Did I make the right decision? Am I saving money? Would I do it this way again? Yes, yes and yes if you choose to visit Suncenter Fluid Control Equipment and make your enquiry.

Custom message