Persist in axial piston pump shut down the inspection

by:Suncenter

2020-09-03

Stop checking is when the axial plunger co2 transfer pump manufacturer in the absence of cleaning engineering during shutdown, arranged by the timing, fixed-point inspection, cleaning, maintenance work.

Service inspection can guarantee the axial plunger pump manufacturer has remained intact readiness, prevent such as loss, frost crack cause unnecessary losses.

During most of the cleaning company in the absence of cleaning engineering, axial plunger co2 transfer pump manufacturer will be parked in the open air base.

At this time, the natural factors such as rain and snow, ice, sun exposure can cause harm to the axial plunger pump manufacturer.

At the same time, the temporary use, curious pull out, remove the view of man-made factors such as axial plunger pump manufacturer can also cause harm.

If during the inspection of the management, will produce large loss.

Service inspection should first clear responsibilities, division of responsibility, responsibility to the people.

For each axial plunger pump head of the inspection.

Enterprises having conditions of cleaning and maintenance can be determined separately on the head, it can focus on security personnel for maintenance work.

At the same time can also be a personnel responsible for the number of axial piston pump maintenance work.

The pump electrical maintenance work to be done by personnel of the unit.

Bar staff, free disassembly, pull out and high pressure cleaning pump group, prevent the man-made fault.

Shut down the inspection regulations, clear content, established for each axial plunger pump fixed format of the book review, facilitate inspection personnel item by item, check processing, also facilitate the supervision and review of management personnel.

Among them, should include the following items: (

1)

Date of inspection, cleaning, maintenance responsibility, responsible and acceptance, acceptance;

(

2)

Complete cleaning, prevent and check content;

(

3)

High-pressure pump inspection project, diesel engine inspection projects, accessory examination, moving parts lubrication inspection project;

(

4)

Turning to check, the commissioning inspection conditions;

(

5)

Battery liquid density, liquid level height check items such as;

(

6)

Control element is complete, connect the solid inspection project;

(

7)

Control circuit, such as joint trace open check project;

(

8)

The examination such as connecting pipe leaks, open project;

(

9)

Winter water tank, oil cooler, high-pressure pump diesel engine oil cooler, water filters, water tanks of antifreeze check project;

(

10)

During the period of change garments according to the shall check fuel grades according to the season change.

In addition, should use the maintenance regulation standard maintenance work.

Shall stipulate, for example, those responsible for freeze protection drainage work, use compressed air for tank diesel engine, diesel engine oil cooler, high-pressure pump oil cooler, water filters and the pipeline purging, safeguard corner place no residual water.

Each enterprise can according to own actual situation, adjust and formulate corresponding inspection content.

Can be divided into weekly inspection content, monthly inspection content.

As far as possible to facilitate implementation of inspection work, cost saving, easy to check.

At the same time, the company management personnel shall organize supervision and inspection, often prevent inspection become a mere formality.

Keywords: oil co2 transfer pump power plant, the axial plunger pump manufacturers, variable plunger pump manufacturers

Clouds of hydraulic pressure pump failures surround the world of hydraulic pressure pump in particular, simply because people don’t pay as much attention to the gas booster as they should do.

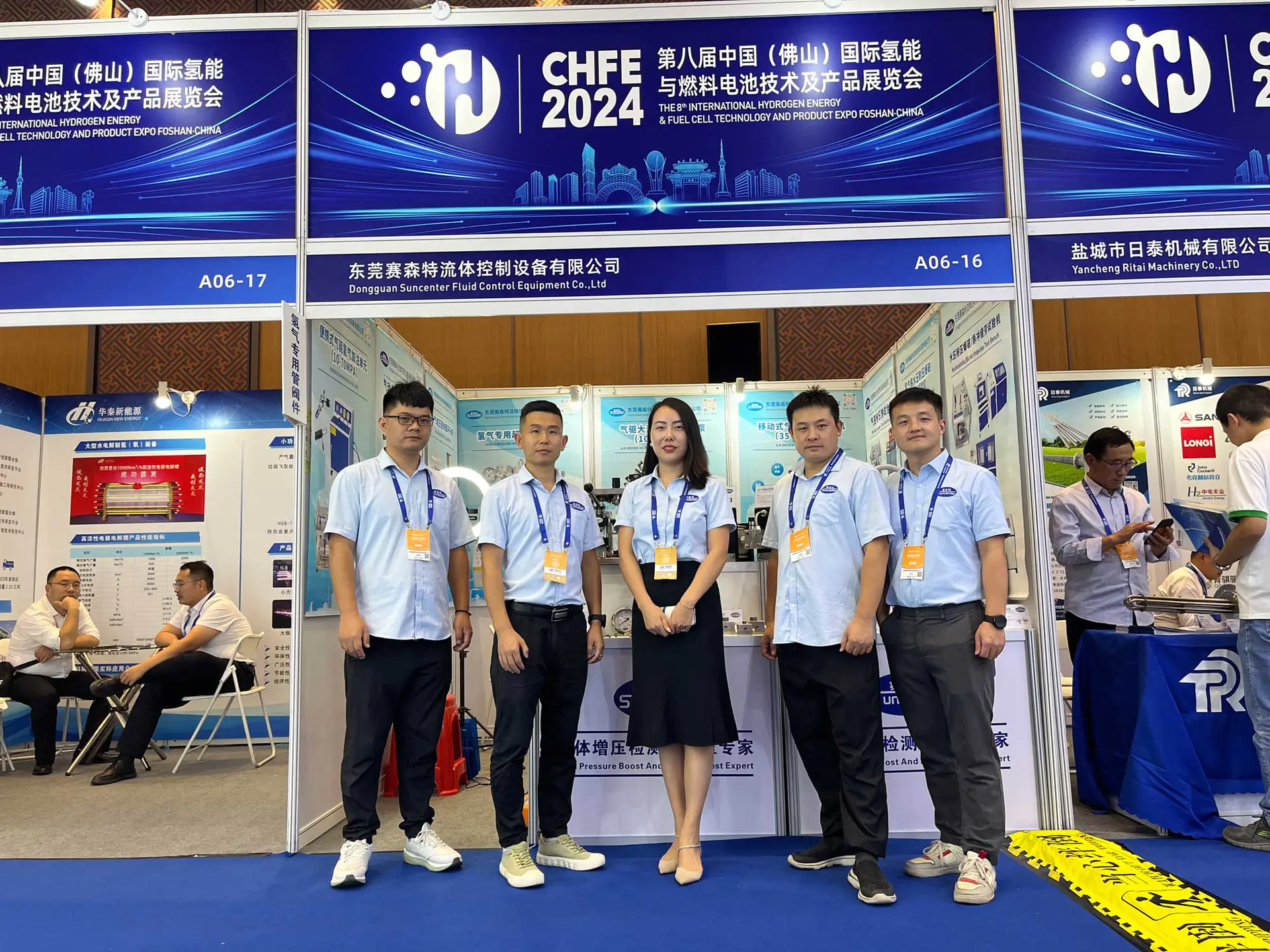

Dongguan Suncenter Fluid Control Equipment Co., Ltd’s goal is to achieve customer satisfaction through excellence in design, supply chain management, manufacturing and repair solutions.

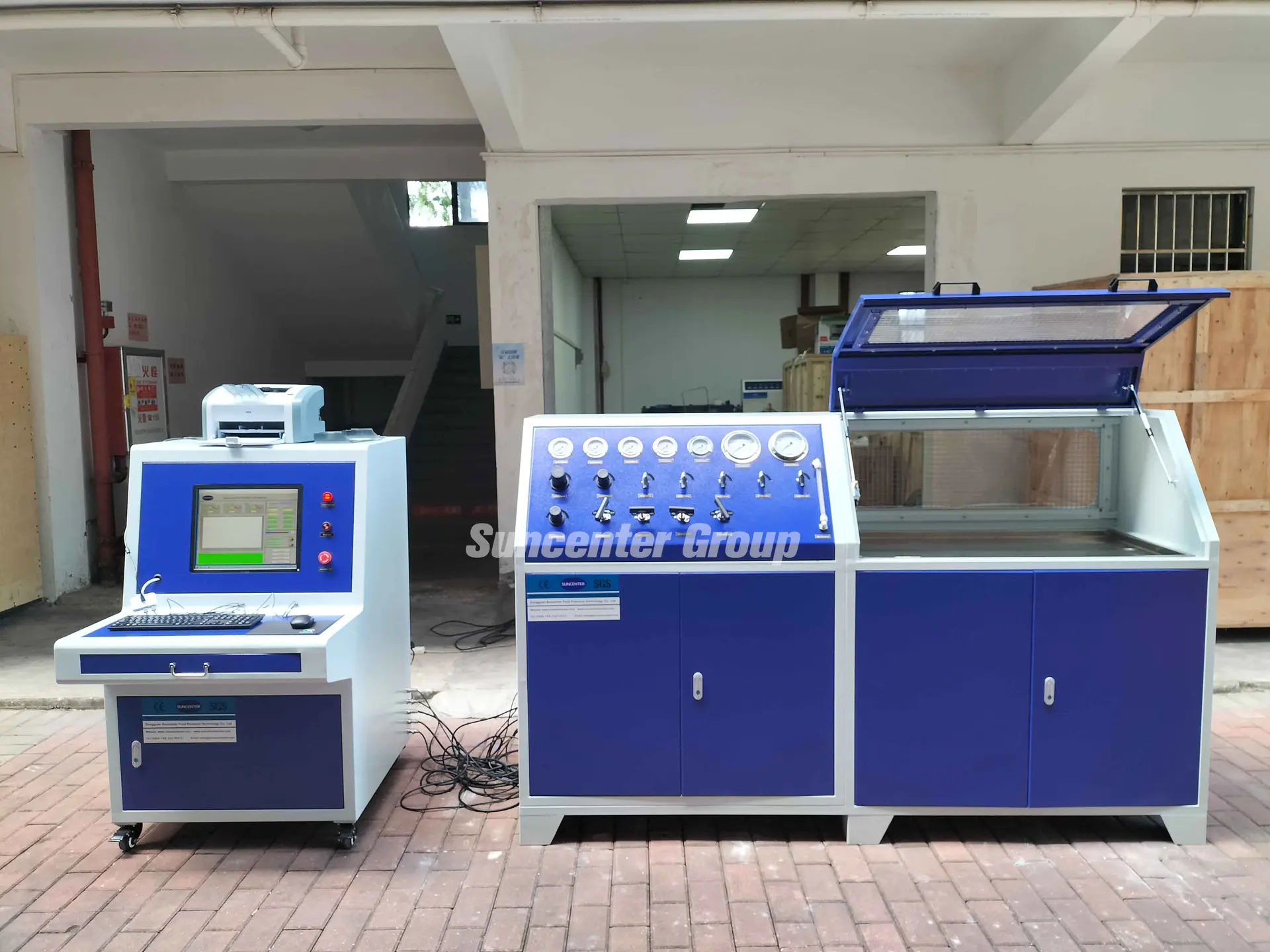

We are professional in manufacturing gas booster, and always emphasize the technology and quality during the producing procedure.

Clouds of hydraulic pressure pump failures surround the world of hydraulic pressure pump in particular, simply because people don’t pay as much attention to the gas booster as they should do.

Dongguan Suncenter Fluid Control Equipment Co., Ltd’s goal is to achieve customer satisfaction through excellence in design, supply chain management, manufacturing and repair solutions.

We are professional in manufacturing gas booster, and always emphasize the technology and quality during the producing procedure.

Custom message