The operation of high pressure reciprocating pump inspection instructions and stop pump

by:Suncenter

2020-08-06

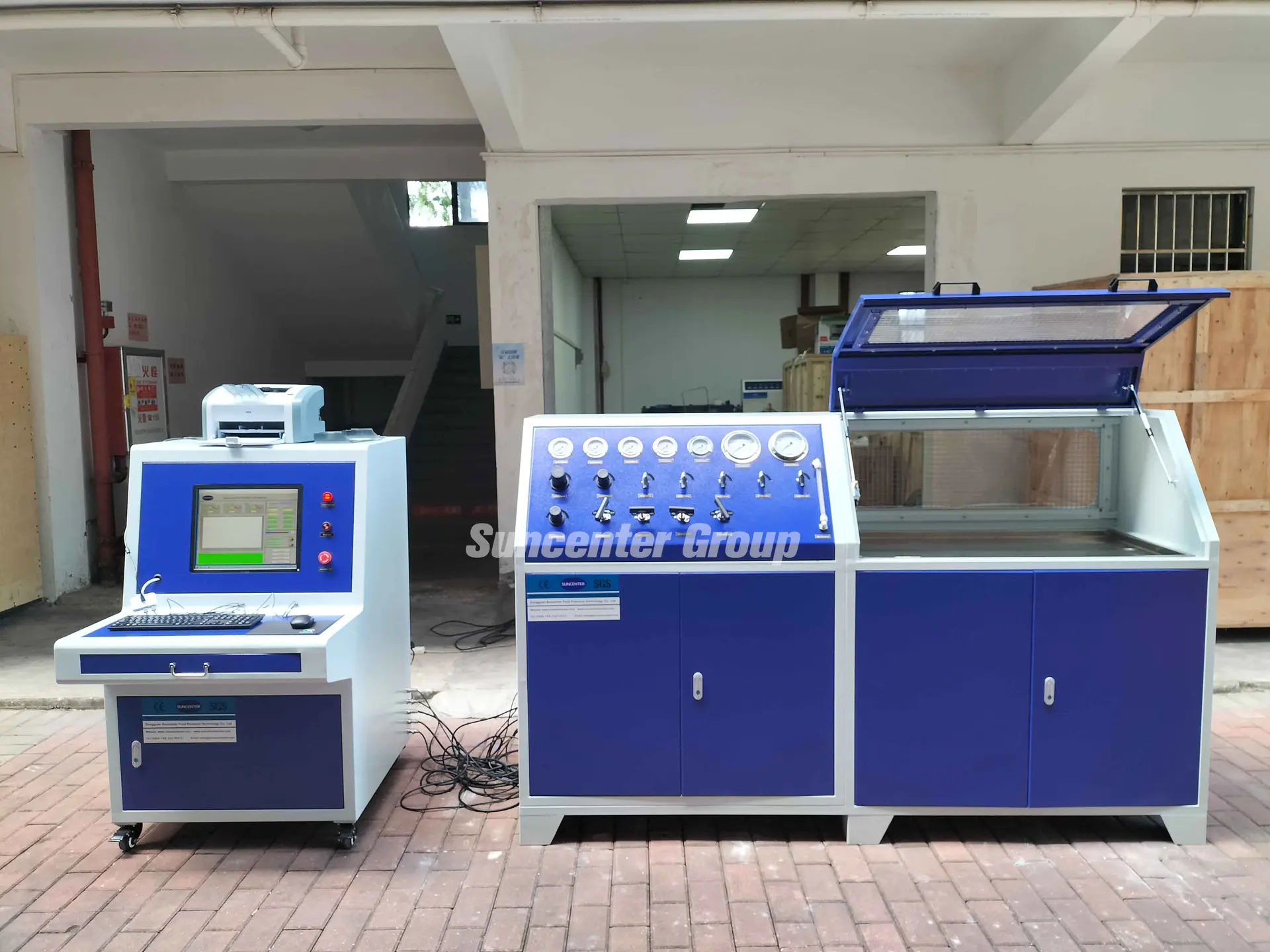

power check and stop the pump in the equipment operation instructions for high pressure reciprocating pump of this kind of pump operation, is the high pressure reciprocating pump operation, the following will explain in detail to three aspects of content, is for the pump needs to be checked before operation and stop pump order and emergency stop pump, so that we can through these, to further understand the high pressure reciprocating pump, and high-pressure pump in this field.

1.

Need to check before the operation of high pressure reciprocating pump in high pressure reciprocating pump operation, the need to check before the operation, and is to know and grasp, to use in the practical work is very good luck.

Its specific content, it is as follows: (

1)

High pressure reciprocating pump after the installation is complete, should inspect, major, is for the connection is solid, its concentricity is guaranteed.

And, if you have exposed the rotation of the part, so if there is a protective device to protect.

(

2)

Before starting the pump in, is to check whether the in and out of the pipe bracket fastening, the suction pipe was clear, and the filter can be normal, 1 can't be missed.

2.

Power plant stop order this pump, the pump for high pressure reciprocating pump operation, is also should be taken seriously and, cannot careless.

The main work and steps, is as follows: (

1)

For hydraulic press receives 'can stop' signal, then water added enough water storage tank.

(

2)

Will be crushed under the plug and power cut-off valve, then cut off the water pump power.

(

3)

Keep the high pressure reciprocating pump shut down and cut off the power of the lubricating oil pump.

At the same time, the closed cooling water valve.

Note that the pump can't load down.

3.

High pressure reciprocating pump emergency stop pump high pressure reciprocating gas booster pump operation, what kind of conditions, when there is emergency stop of the pump?

This problem, the concrete answers, it is as follows: when the pump overtemperature and overpressure phenomenon, and some measures are taken, cannot relieve or eliminate.

Or is that its work have a sound and vibration.

And gas booster pump failed components, such as solenoid valve, or pressure gauge meter display abnormal, such as these are to immediately stop the pump.

In addition, when high pressure reciprocating pump suddenly serious leaks, and cannot be stopped, also want to immediately stop the pump.

Keywords: oil pump power plant, the axial plunger pump manufacturers, variable plunger pump manufacturers

Wow, this sounds like a bit of a cruel question, but it is a vitally important question to ask yourself if you are struggling with your hydraulic pressure pump and you would like to stop the gas booster problem.

Dongguan Suncenter Fluid Control Equipment Co., Ltd builds value for our investors through the strength of our customers’ satisfaction and by consistently producing superior operating results.

Though the cost of these sustainability initiatives as gas booster can be high, harnessing the power of an ethical supply chain to appeal to conscientious consumers can be a smart move both ethically and financially.

Depending on the scale of the service, Dongguan Suncenter Fluid Control Equipment Co., Ltd might also need to hire and manage an overseas workforce and comply with regulatory requirements.

Wow, this sounds like a bit of a cruel question, but it is a vitally important question to ask yourself if you are struggling with your hydraulic pressure pump and you would like to stop the gas booster problem.

Dongguan Suncenter Fluid Control Equipment Co., Ltd builds value for our investors through the strength of our customers’ satisfaction and by consistently producing superior operating results.

Though the cost of these sustainability initiatives as gas booster can be high, harnessing the power of an ethical supply chain to appeal to conscientious consumers can be a smart move both ethically and financially.

Depending on the scale of the service, Dongguan Suncenter Fluid Control Equipment Co., Ltd might also need to hire and manage an overseas workforce and comply with regulatory requirements.

Custom message