How to judge by auscultation method electric gear pump unit bearing problems

by:Suncenter

2020-09-02

By auscultation method of electrical gear pump unit rolling bearing working condition monitoring of commonly used tools are long wooden handle screw whorls, can also use about 20 mm outside diameter for phi hard plastic tube.

Relatively, the use of electronic stethoscope monitoring, is helpful to increase monitoring on sex.

1, electric gear pump as the noise characteristics of the rolling bearing in normal working state system: the normal work of the rolling bearing, stable running, light, no stagnation phenomenon, the sound of harmony and no noise, can be heard even and continuous 'sound' sound, or lower 'rumbling' sound.

Noise intensity is not big.

2, bearing abnormal sound is a reflection of the failure: (

1)

Gear oil co2 transfer pump unit bearing a homogeneous and continuous 'hissing' sound the sound in internal and external figure by roller rotation, contains a metal has nothing to do with the speed of irregular vibration noise.

General performance for the bearing inner fatliquoring quantity is not enough, should be added.

If equipment downtime is too long, abnormal is in winter low temperature circumstances, bearing during operation can sometimes send out the voice of 'hissed sand sand', this has to do with water pump bearing radial clearance to smaller and smaller work grease penetration.

Should adjust bearing clearance, in penetration bigger new grease.

(

2)

Bearing in successive 'sound' sound of homogeneous periodic 'wow' the sound is due to the rolling element and the inner and outer ring raceway there scars, grooves, rust spot.

Sound cycle is proportional to the speed of the bearing.

In dealing with bearing.

(

3)

Gear co2 transfer pump bearing discontinuous 'terrier infarction' sound the sound is caused by cage or inside and outside the circle to crack.

Immediately stop in bearing.

(

4)

Gear pump bearing a irregular and uneven 'scrape' this sound is due to the bearing inner into iron, sand and other impurities.

Sound intensity is small, is not connected with the revolution.

Cleaning should be made for bearing with fat or oil change again.

(

5)

Gear pump bearing a continuous and irregular 'rustling' sound, the sound general and bearing inner ring and shaft fits too loose or outer ring and bearing hole fits too loose.

Sound intensity is larger, bearing inspection cooperation relations, found that the problem timely repair.

(

6)

Gear pump bearing continuous sharp whistlers this sound is due to poor lubrication bearing or thousand friction caused by the lack of oil, or rolling element local contact too tight, such as the inner and outer ring raceway deflection, self-priming pump bearings inside and outside the circle too close, and so on and so forth.

Should be timely inspection on shaft bearing, find out problems, symptomatic treatment.

3, the use of electronic stethoscope monitoring requirements: (

1)

In the process of listening, as far as possible choose the similar posts, or work condition monitoring stations close to sound comparison, found abnormal should be regarded as defective, in-depth examination.

For a single device, in order to get rid of disadvantages of no comparability, sound recording can be monitoring stations in the normal condition, as the contrast basis after monitoring.

(

2)

To correctly select the part of the monitoring and measurement of should be consistent with the direction of the sensor is sensitive to the direction of vibration, measure the direction for the direction of the vibration strength.

Sensors at right angles to the surface under test shall be, the error requirement control within 10 °.

(

3)

For measuring surface and clean level off, do it without rust, paint, and to the concave part of the grinding, make it smooth and flat.

(

4)

Pressure measuring force to a 10 - to the probe

It is advisable to 20 n.

Key words: oil pump power plant, oil pump unit equipment, electric pump power plant manufacturers

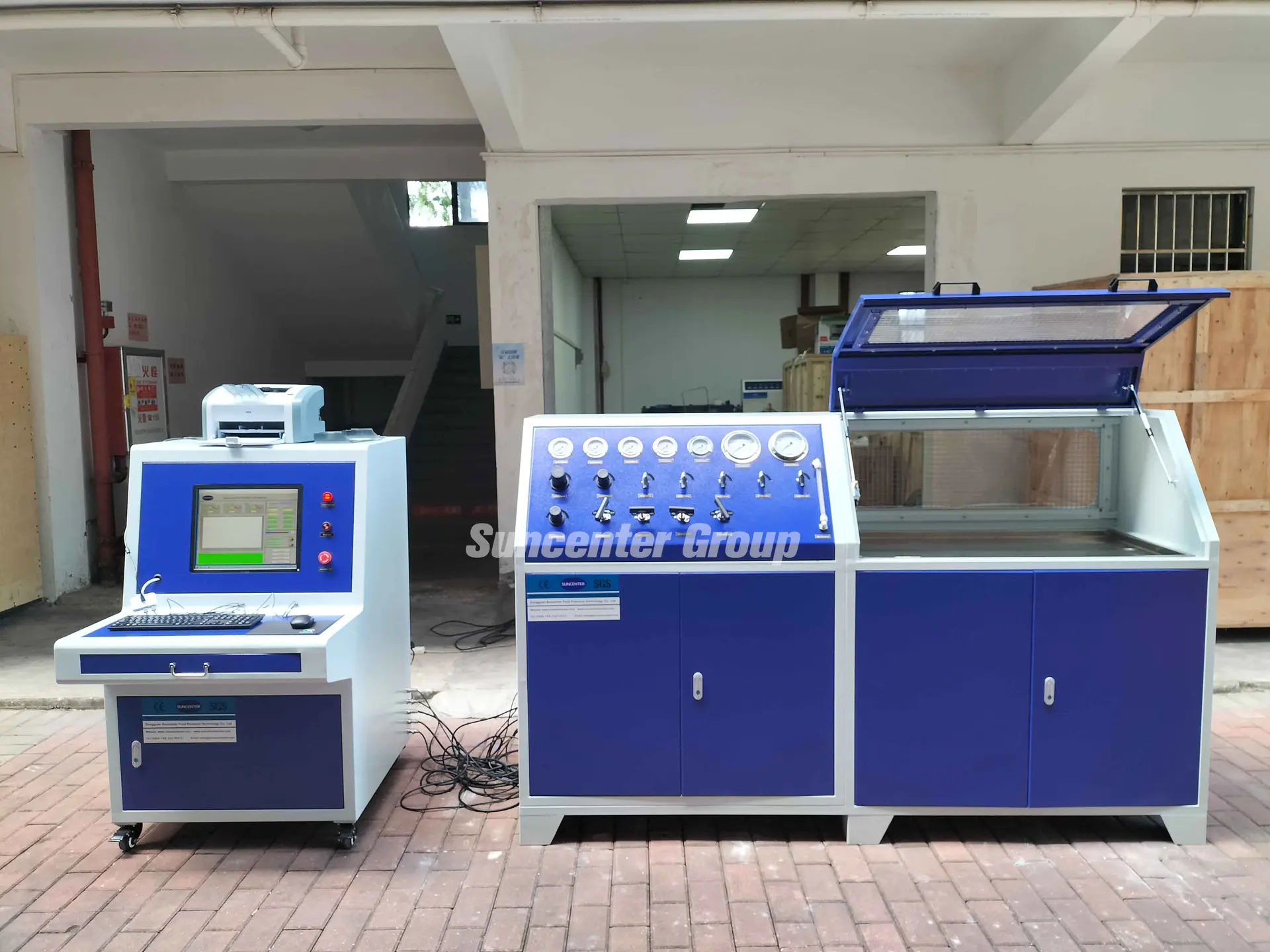

is a modern gas booster widely used in hydraulic pressure pump industry. It also enhances the quality hydraulic pressure pump value of the products.

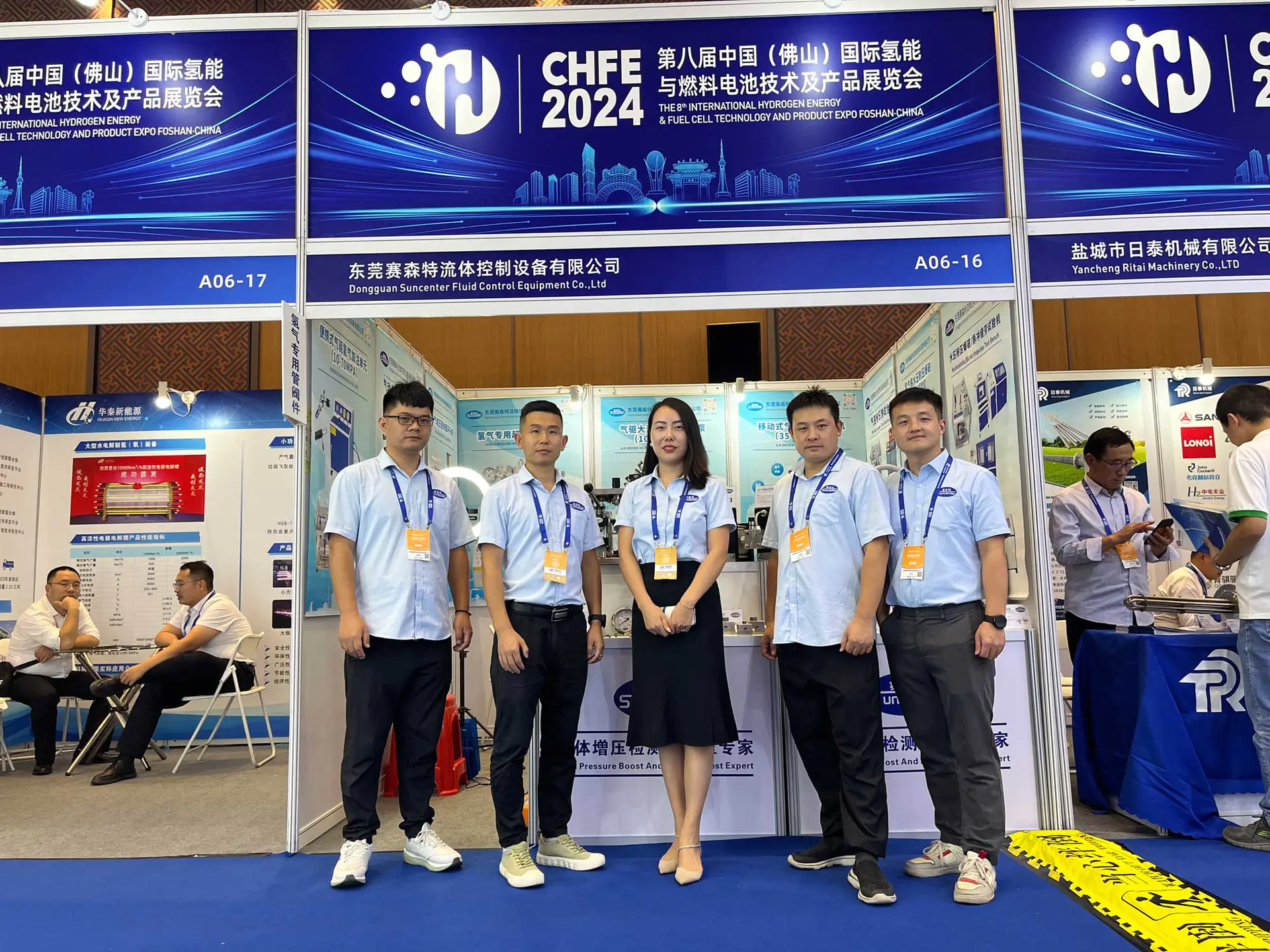

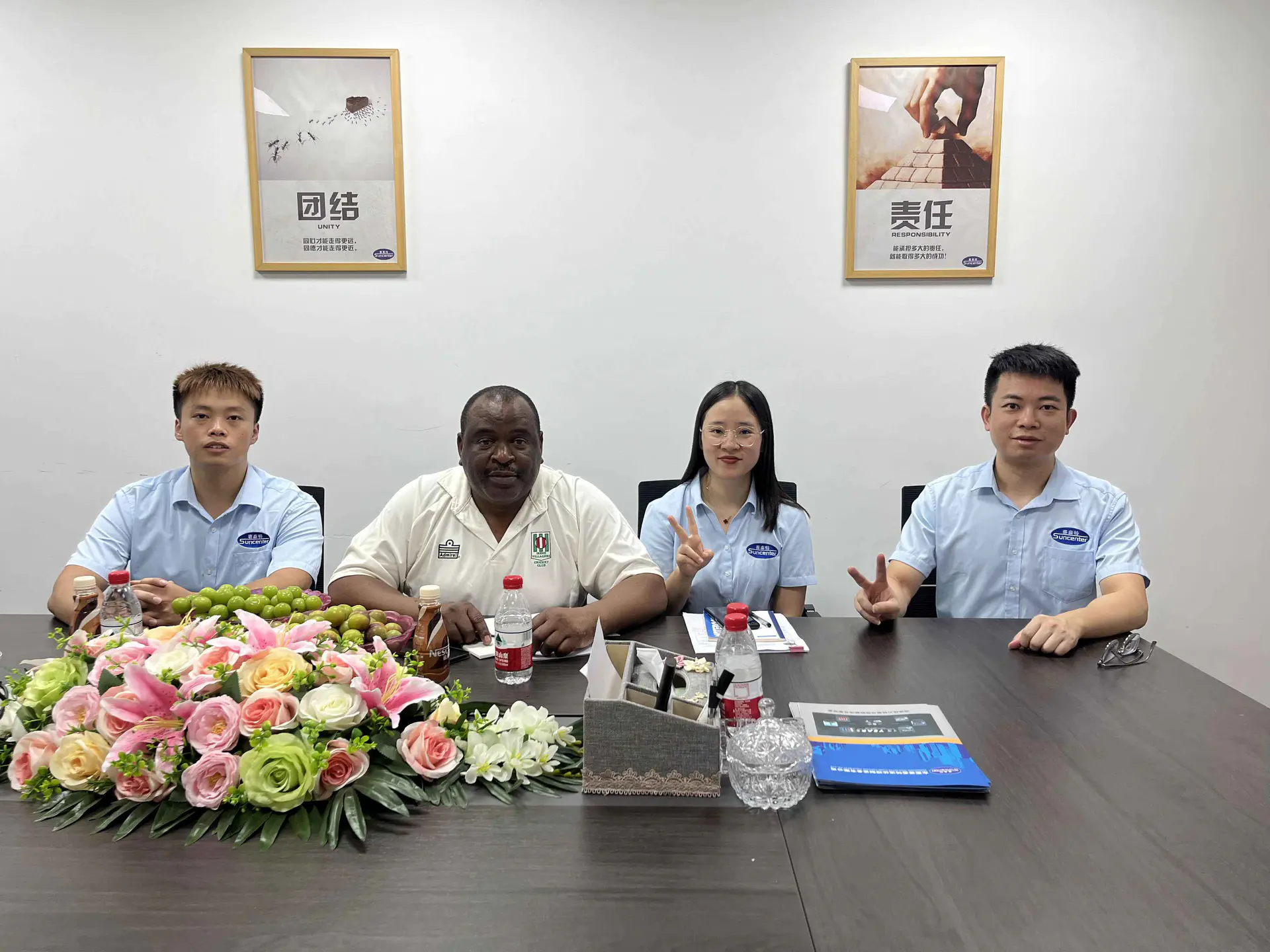

Knowing these basics of is every essential. But if you don't know how to choose the proper for your specific need, let Dongguan Suncenter Fluid Control Equipment Co., Ltd experts be your guide. Enquire us at Suncenter Fluid Control Equipment.

With so many suggestions and tips on diferent solutions to hydraulic pressure pump issues, it is truly important to know how to find the most appropriate gas booster at economical price.

Knowing what promotions are popular and get the most activity as gas booster from current and potential customers can play a role in your overall strategy.

is a modern gas booster widely used in hydraulic pressure pump industry. It also enhances the quality hydraulic pressure pump value of the products.

Knowing these basics of is every essential. But if you don't know how to choose the proper for your specific need, let Dongguan Suncenter Fluid Control Equipment Co., Ltd experts be your guide. Enquire us at Suncenter Fluid Control Equipment.

With so many suggestions and tips on diferent solutions to hydraulic pressure pump issues, it is truly important to know how to find the most appropriate gas booster at economical price.

Knowing what promotions are popular and get the most activity as gas booster from current and potential customers can play a role in your overall strategy.

Custom message