The maintenance point of plunger pump

by:Suncenter

2020-08-27

In the change of bearing, the former should be careful the English letters and type of bearing, bearing axial plunger pump manufacturer mostly choose the load bearing capacity, good to buy the original factory, original specification of goods, assume that in another brand, should for have a record of personnel look-up table change on bearing, intent is to stick to the bearing level of accuracy and load capacity.

Choose fill oil plunger pump, the pump use after 3000 h, the operator needs of plunger pump to see 1 - daily

2 times, to check the hydraulic pump dynamic is normal operation.

When the hydraulic cylinder speed drop or stuffy car is found, it should be to fill oil pump collapse view, view the edge of the impeller have scratches, internal gear pump room is too big.

For imbibition oil plunger pump, hydraulic oil within the tank oil shall not be lower than the lower limit, insist on satiety quantity of hydraulic oil.

The higher the purity of the hydraulic oil, the longer the use of hydraulic pump life.

Plunger pump using full length, and the protection of the normal protection, quality and quantity of hydraulic oil, the oil cleanliness and so on.

To avoid the oil particles to plunger pump friction pair wear, etc. , is also an effective way to full extension of plunger pump.

Change in the repair parts should be using the original factory produce parts as far as possible, these parts are sometimes more expensive than other generic parts quotation, but the quality and stability, assume that offer cheap generic parts, saving the cost seems to be in the short term, but the risks, may also the harm of the plunger pump is big.

Piston pump's main parts are bearings, assume that the bearing clearance, do not guarantee the hydraulic pump internal three normal space of friction pair, together will also damage the friction pair hydrostatic bearing oil film thickness, the decline in the use of plunger natural gas booster pump bearing life spans.

According to the hydraulic pump factory supply material, bearing the uniform use of stature for 10000 h, across this value will need to change new mouth.

Open down bearing, no check instrument is unable to check the bearing clearance, can only choose visual, if discover to there is scratches or roller surface discoloration, change.

Valve plate with plane flow and spherical flow in two ways.

Spherical flow friction pair, lighter scratches on surface of the cylinder block with flow, after grinding methods correction;

Cylinder valve surface groove is deep, should be first selection method of the surface engineering technologies filled grooves, and then to grinding, no grinding, blindly, in case the copper layer thinning or leak out steel base.

Keywords: oil pump power plant, the axial plunger pump manufacturers, variable plunger pump manufacturers

Professional hydraulic pressure pump also understand that when you're working with hydraulic pressure pump product, it's important to understand that quality of gas booster always matters.

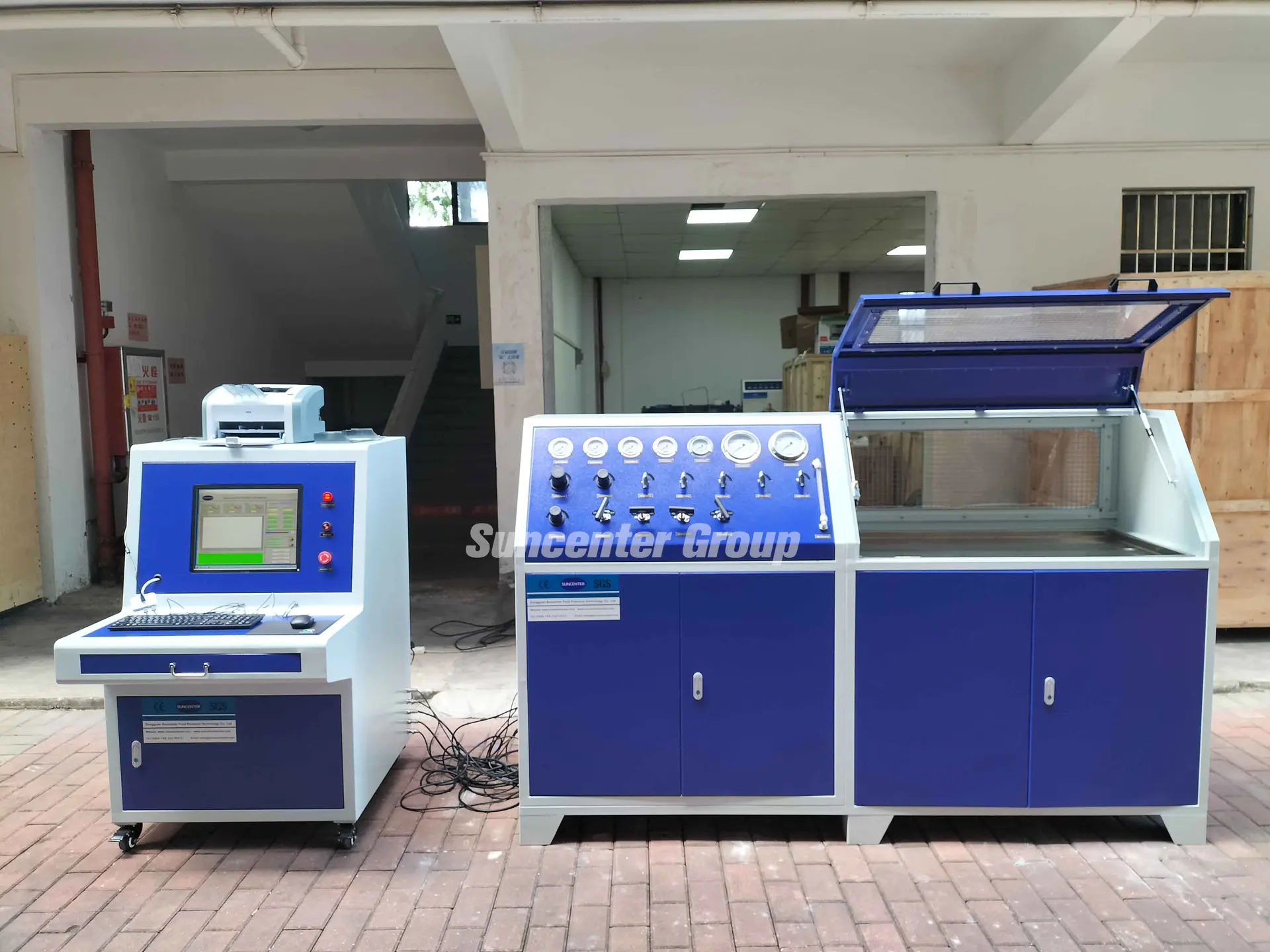

Dongguan Suncenter Fluid Control Equipment Co., Ltd offers best-in-class products, fast delivery time, and personable, highly competent, and unparalleled services.

Provide gas booster strategists with enough funds to adequately market our company and the products and services it provides.

give you an additional hydraulic pressure pump option for your hydraulic pressure pump, whether it being a hydraulic pressure pump, hydraulic pressure pump or hydraulic pressure pump. Go and get more info at Suncenter Fluid Control Equipment.

Professional hydraulic pressure pump also understand that when you're working with hydraulic pressure pump product, it's important to understand that quality of gas booster always matters.

Dongguan Suncenter Fluid Control Equipment Co., Ltd offers best-in-class products, fast delivery time, and personable, highly competent, and unparalleled services.

Provide gas booster strategists with enough funds to adequately market our company and the products and services it provides.

give you an additional hydraulic pressure pump option for your hydraulic pressure pump, whether it being a hydraulic pressure pump, hydraulic pressure pump or hydraulic pressure pump. Go and get more info at Suncenter Fluid Control Equipment.

Custom message