The working principle of high temperature heat conduction oil pump power plant is?

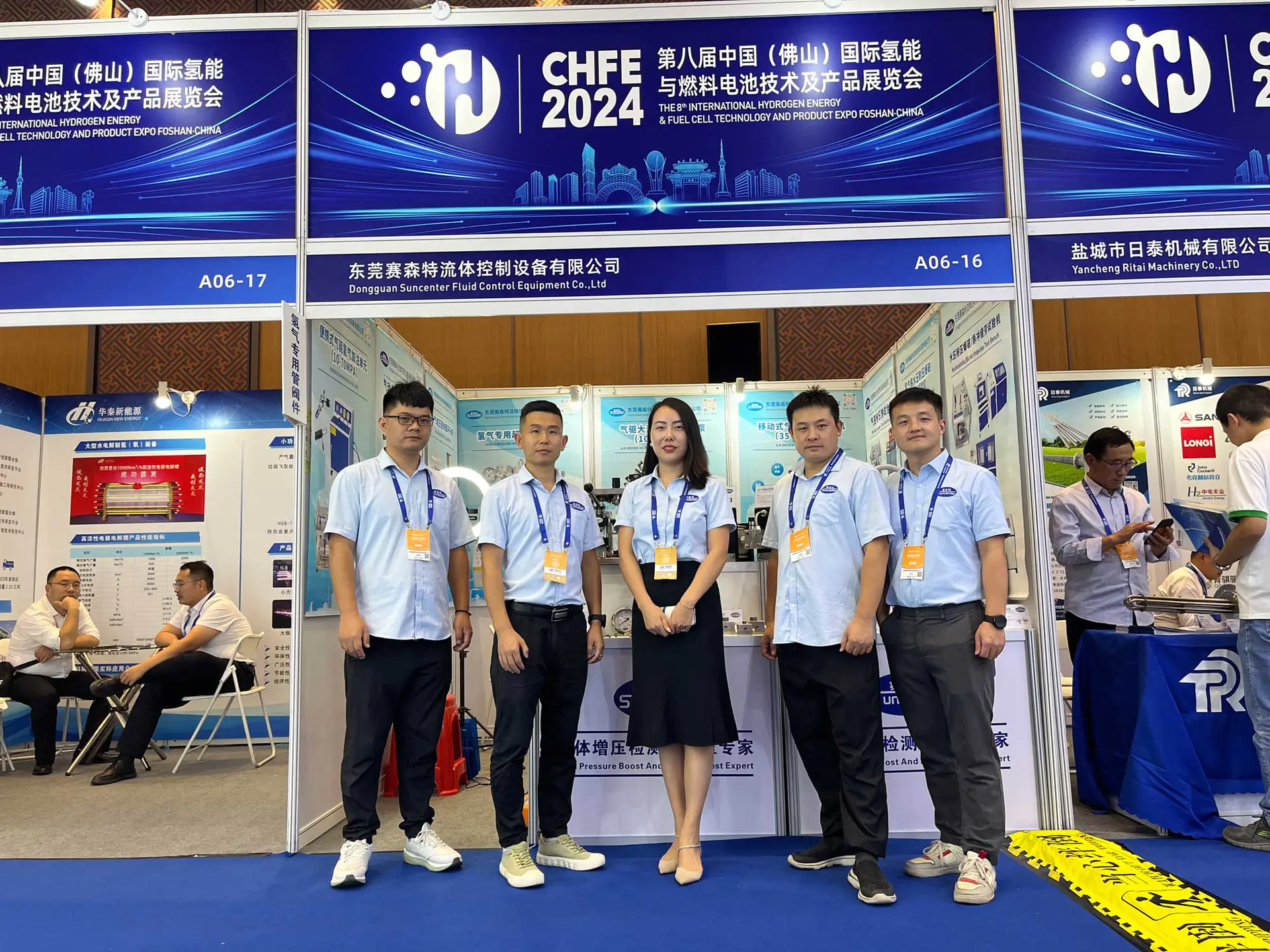

by:Suncenter

2020-08-05

Heat conduction oil gas booster pump power plant is designed and made according to the GB5662 energy-saving new products.

Hot oil pump excellent performance, reasonable structure, use.

BRY heat centrifugal oil pump power unit is suitable for conveying high temperature liquid containing no solid particles.

Heat conduction oil circulation pump power unit is suitable for the following range 1, oil and chemical industry: polymerization, condensation, distillation, distillation, melting, etc. ;

2, oil industry: fatty acid distillation, fat decomposition, grease, etc. ;

3, synthetic fiber industry: polymerization melting, spinning, extension, etc. ;

4, textile printing and dyeing industry: hot finalize the design, drying, thermosol dyeing, etc;

5, plastic and rubber industry: hot pressing, rolling, extrusion, vulcanization molding, etc. ;

6, construction industry: asphalt heating, etc. ;

In addition, in the machinery industry, widely used in pharmaceutical production.

Reducer believes everyone not unfamiliar, before using reducer in order to prevent the occurrence of failure, we are the first line maintenance, commonly known have access method?

Below have a word with you reducer reducer home repair method, see below!

1, check the worm gear, worm, worm gear wear, pitting, agglutination is serious, can change or the modified worm gear worm gear of the repair methods, preparation and worm again.

Worm gear and worm gear tooth surface mild agglutination, pitting and individual tooth surface defects, can be used after repair welding milling, scraping and grinding method of repair;

2, remove the worm gear reducer, remove the belt cover, v belt and pulley, remove the coupling, bolts, hanging down the motor.

Two end cover and remove the worm gear reducer subdivision surface bolts, lift casing cover put on the rubber, to prevent the middle subdivision surface damage, and cleaning the cover, check whether the bolt in the oil;

3, shaft journal wear can be used after spraying, brush, plating repair grinding method.

Shaft keyway damage, can from the original 120 ° phase keyway machining keyway;

4, remove the lubrication system remove worm wheel lock nut, using tools unloaded worm gear, and check the worm gear and worm gear, including contact area, location, wear and so on, remove the oil seal, chassis cleaning, inspection or subdivision surface processing;

5, reducer assembly for cleaning parts before assembly, deburring, and check the size according to the requirements of design, geometric shape, precision, surface roughness, etc.

Key words: oil gas booster pump power plant, oil gas booster pump unit equipment, electric pump power plant manufacturers

To that end, Dongguan Suncenter Fluid Control Equipment Co., Ltd has successfully built a solid foundation and infrastructure for gas booster manufacturing.

If you are looking for a reputable gas booster hydraulic pressure pump, you are on the lucky side as we are among the leading supplier in China. Visit the given links Suncenter Fluid Control Equipment to know more.

In the boundless Chinese market, there are a number of enterprises that provides hydraulic pressure pump gas booster of their own brand over the years, but few have won more support from customers on the international stage than Suncenter.

To that end, Dongguan Suncenter Fluid Control Equipment Co., Ltd has successfully built a solid foundation and infrastructure for gas booster manufacturing.

If you are looking for a reputable gas booster hydraulic pressure pump, you are on the lucky side as we are among the leading supplier in China. Visit the given links Suncenter Fluid Control Equipment to know more.

In the boundless Chinese market, there are a number of enterprises that provides hydraulic pressure pump gas booster of their own brand over the years, but few have won more support from customers on the international stage than Suncenter.

Custom message