Five methods about oil pump unit electric paint dry

by:Suncenter

2020-09-08

Our company production of oil pump power plant are using hot air circulation drying oven to dry, this method is widely applied in the actual production of the hydraulic motor.

power plant before leaving the factory sales have been painted and varnished, varnished windings is mainly to increase the strength of the insulation of the motor winding, motor shell paint is mainly in order to increase the aesthetic, antirust waterproofing, etc.

But how to motor leaching paint, paint to dry?

Quick lime drying put the oil pump motor in a sealed box, in the box and quick lime, using quicklime strong ability of moisture absorption, dry oil pump motor.

This method is safe, energy saving, but the drying time is long, more time consuming.

Dry bulb method using infrared light bulbs or direct light bulb commonly make on the oil co2 transfer pump motor stator winding, change the bulb power, can change the temperature.

Can also be measured by core winding temperature, temperature control and measurement of the oil pump motor insulation resistance, etc. Meet the requirements can be stopped after drying.

Current drying the oil co2 transfer pump motor stator winding is connected in connection mode, then to coil zhongtong into the current, the use of copper winding itself consumption hot baked dry.

Main connection mode series heating, star heating type, triangle heating type, etc.

Either way, the assigned to each phase winding current baking it should be controlled in 60% to 80% of the rated current, electricity 6 ~ 8 h h, winding temperature of 70 ℃ ~ 80 ℃ advisable.

Iron loss drying method with insulation wire wear around the oil pump motor stator core, plug in the ac power to produce alternating magnetic flux, formation of eddy current in the stator core, stator core heat, drying oil pump motor.

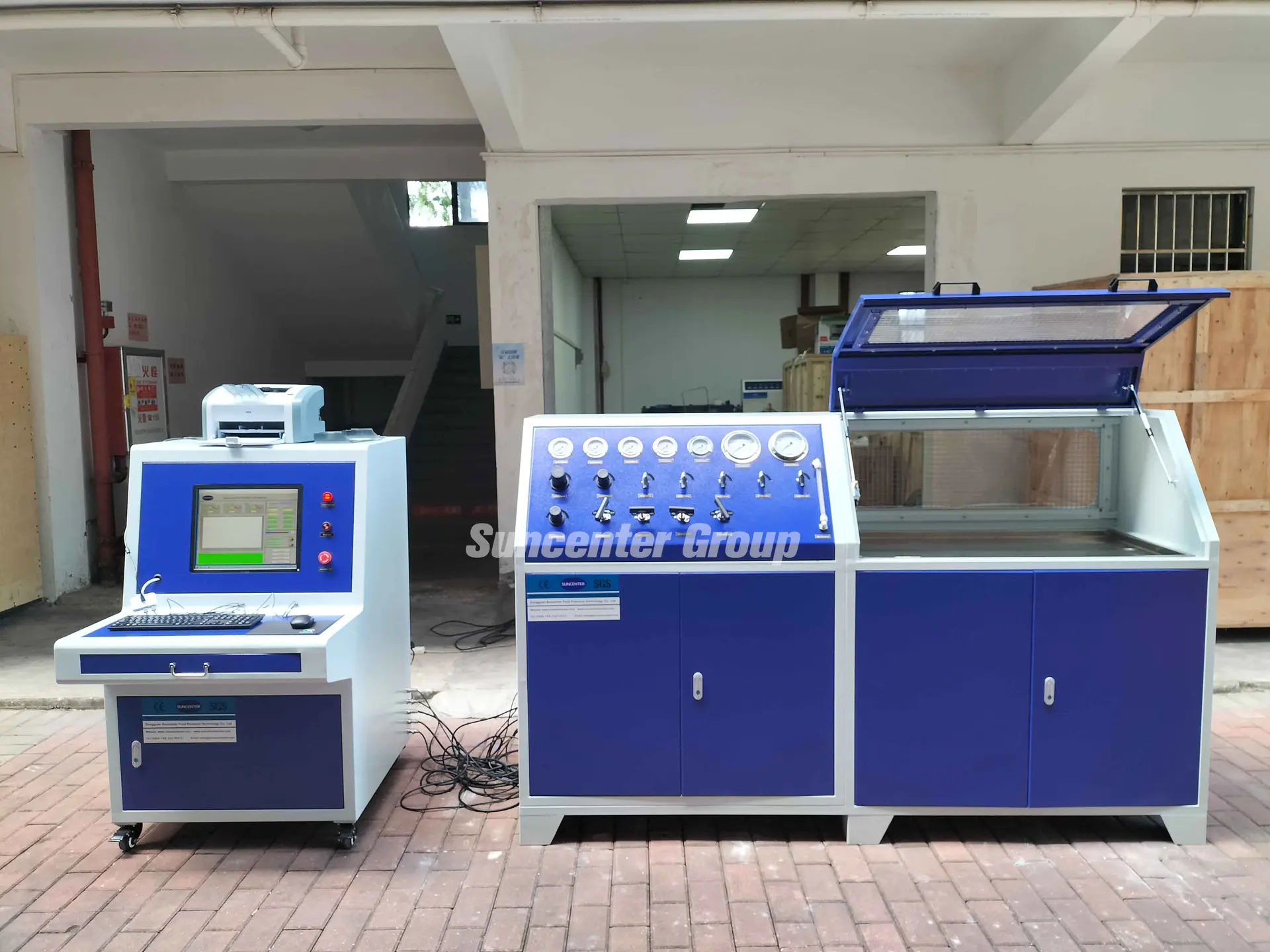

Electric hot air circulation drying oven is also called hot air circulation drying oven, oven made from sheet metal, heating wire is installed in the bottom of the box body and two sides wall, outside of the heater cover with metal, on the one hand can make by iron plate heat conduction, the evenness of temperature in the cabinet.

On the other hand to prevent paint directly drops of the heater, cause a fire, burning the oil pump motor.

In the process of electricity, oven temperature with alcohol thermometer monitoring, the note shall not exceed the specified value, shall not adopt any mercury thermometer to monitor the temperature of oven in case accident broken thermometer, mercury drop into the oil pump motor stator winding, winding short circuit.

Another oven top left out moisture and solvent steam vent.

Keywords: axial plunger pump manufacturers, variable plunger pump manufacturers, oil co2 transfer pump power plant manufacturers

Suncenter needs to be able to reach social users in a way that complements what the brand is doing if they want to succeed at social commerce.

Applied Materials’ mission is to be the leading supplier of gas booster worldwide-through innovation and enhancement of customer productivity with systems and service solutions.

Dongguan Suncenter Fluid Control Equipment Co., Ltd, which contributes itself on gas booster for creating more useful application.

Suncenter needs to be able to reach social users in a way that complements what the brand is doing if they want to succeed at social commerce.

Applied Materials’ mission is to be the leading supplier of gas booster worldwide-through innovation and enhancement of customer productivity with systems and service solutions.

Dongguan Suncenter Fluid Control Equipment Co., Ltd, which contributes itself on gas booster for creating more useful application.

Custom message