The working principle of pump power plant?

by:Suncenter

2020-08-24

The working principle of pump power plant?

Oil natural gas booster pump electric unit powered two-way pump output pressure oil, driven by hydraulic integrated block element to control the valve opening and closing of the piston rod.

Motor, oil pump, hydraulic control valve and hydraulic cylinder can be installed on the same axis, also need devices in different axis, simply connect the control power of the motor, can make the reciprocating motion of the piston rod.

Hydraulic control valve is made up of the overflow valve, control valve, hydraulic one-way valve group, according to the working point for design of hoist the combination of different oil valve satiety the requirements of the condition.

The piston rod is adjustable by positive and negative rotation control motor has a flexible motion, schedule control accurate, overload protection performance.

When run up, increases pressure in the oil to the setting of limits, the overflow, overflow valve quickly and accurately implement the overload protection, electric operation within the rating will not burn.

Open/close the oil path integration block designed self-locking mechanism, when the hoist is scheduled to run to terminal, motor automatically stop running, the piston rod is locked in this position, in the state of pressure keeping.

Oil pump electricity unit regulating principle, the inside of the inclined shaft type variable pump with a rod by the side of the cylinder body, can make the lever to push the oil pressure control device of different cylinder block, make its tilt Angle change, the plunger in the process of rotating schedule change, and then flow change.

Injection molding machine standby mode, the flow is zero, the motor speed constant.

Inverter how variables: change the frequency of the alternating current frequency converter, the mains frequency 50 hz into 5 ~ 50 hz (

Is directly proportional to the voltage corresponding to the change)

, so that the asynchronous motor speed change in 10% ~ 100%, deserve to go up after quantitative natural gas booster pump, oil flow and transformation in 10% ~ 100%.

Frequency converter is a strong current electronic device, itself energy consumption, energy saving effect is worse than variable pump.

Asynchronous motor is used for constant speed, not considering the optimization of rotor inertia, the rotor acceleration deceleration takes time, so the average user feels inverter slowing productivity.

And variable pump vane pump is more, by centrifugal force makes the blade pressure pump shell sealing, speed drops, centrifugal force, internal leakage increase, the oil pump efficiency decline.

Actually the inverter is added at the time of injection molding machine modification, only involves the wiring change, volume natural gas booster pump is much simpler than change.

New injection molding machine is not match the plunger pump frequency converter and comparison: the gear pump plunger pump (

Variable pump)

Volumetric efficiency is about 95%, structure of precision, for pollution tolerance is not high, the noise is bigger.

But the variable characteristics can reduce the servo motor torque load, reduce the current and its heat.

Gear pump (

Quantitative pump)

Volumetric efficiency is less than 90%, the structure is simple, the cost is not high, the noise is not big, is tolerant of oil is bigger.

Keywords: oil pump power plant manufacturers, oil pump electric unit types, and the oil pump power plant USES

For the study, researchers defined Suncenter as strategies to foster some social good, including programs that benefit community engagement, diversity, the environment, human rights and employee relations.

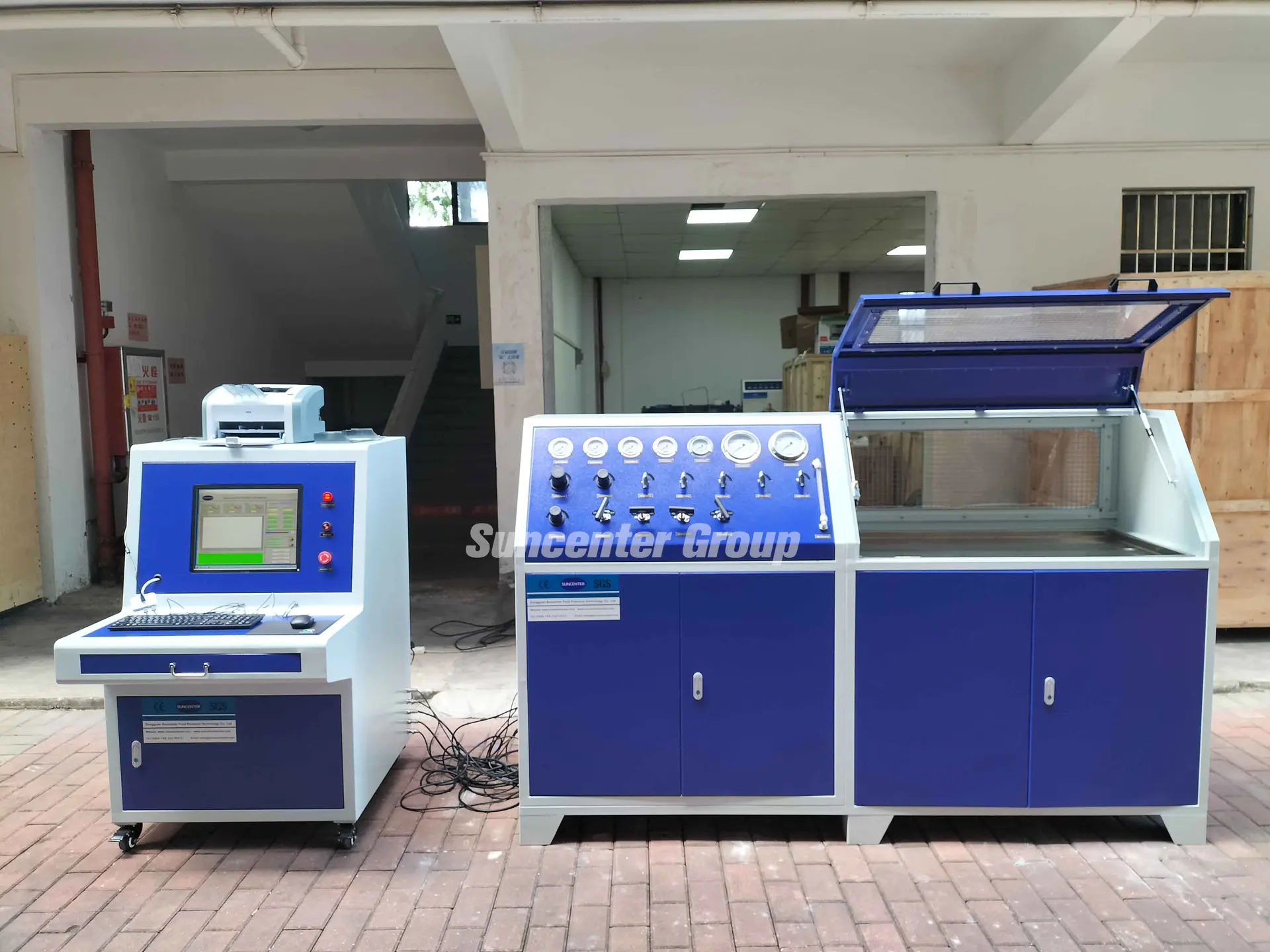

You can count on Dongguan Suncenter Fluid Control Equipment Co., Ltd to be your one stop shopping site for most of the quality products you are searching for. We strive to offer a wide variety of products for you to learn about and to purchase.

We utilize our expertise to develop services that add value at each phase of thegas booster development cycle. We evaluate and implement new strategies in response to changing customer profiles and market conditions.

hydraulic pressure pump gas booster quality is more important because some how it affects to our hydraulic pressure pump. So grab good quality .

A quality monitoring group created for ensuring that Dongguan Suncenter Fluid Control Equipment Co., Ltd manufactures gas booster accoording the strictest standard.

For the study, researchers defined Suncenter as strategies to foster some social good, including programs that benefit community engagement, diversity, the environment, human rights and employee relations.

You can count on Dongguan Suncenter Fluid Control Equipment Co., Ltd to be your one stop shopping site for most of the quality products you are searching for. We strive to offer a wide variety of products for you to learn about and to purchase.

We utilize our expertise to develop services that add value at each phase of thegas booster development cycle. We evaluate and implement new strategies in response to changing customer profiles and market conditions.

hydraulic pressure pump gas booster quality is more important because some how it affects to our hydraulic pressure pump. So grab good quality .

A quality monitoring group created for ensuring that Dongguan Suncenter Fluid Control Equipment Co., Ltd manufactures gas booster accoording the strictest standard.

Custom message