The axial plunger pump principle and theory

by:Suncenter

2020-08-10

Due to friction and rolling roll and aluminum plate appearance, axial plunger pump principle: aluminum belt in the process of cold rolling system.

Its appearance will produce fine alumina powder falls off and adsorption, rolling oil and suspension components will remain in the aluminum plate surface, the aluminum plate with composite, coating and other waste processing beneficial effects.

And because eye _ when he bends straightening strip on the roll intense bending deformation occurs, a local into strip tension on strip of tension roller pressure, and form a friction drive roller group.

Therefore, if the band looks without the plunger pump, when the deformation of alumina powder, with oil as x attached to the tension roller of roller surface, the roll surface wear, and aluminum plate slightly injured, so need through the plunger pump axial plunger pump manufacturers.

Plunger pump is to take advantage of pressure gas booster pump plunger pump medium pressure, to non-contact strip appearance spray or contact scrub, to dissolve oil material on the surface of the aluminum powder falls off to the plunger pump medium, then through drain and squeeze roller of high pressure air purging, hot air drying, even to get a clean dry aluminum strip.

From time to time at the same time, through the circulation and online supplementary plunger pump medium filtering system used at the same time, make the plunger pump medium adhere to adequate and clean, and greatly save heat and plunger pump medium.

At present, aluminum processing industry of stretch bending straightening machine commonly used medium has a plunger pump plunger pump agent (

Or solvent oil)

Softened water, chemical solvents, and each have advantages and disadvantages.

Aerospace, household appliances, decoration materials and beverage industry such as increasing demand for aluminium strip and foil, high-pressure plunger pump application in aluminum plate with plunger pump equipment in recent years with the rapid development of national economy in our country.

The PS substrate, lu: su belt, capacitor foil, and so can the rapid development of high precision aluminum plate strip.

These products strict in straightness, cleanliness, and high precision aluminium strip is usually adopted the rolling cooling and lubrication oil residue of rolling oil and its appearance of aluminum powder, thus to obtain good appearance quality, need plunger pump to remove the residue.

In addition to flatness requirement on aluminum strip and high stretch bending straightening, stretch bending straightening strip in secondary under the action of bending and gradual plastic sheet ZhongBing release internal stress, to improve the plate strip produced during cold working waveform, warping, lateral bending and potential defects such as bad profile, considering from the straightening process, you first need to strip the appearance of plunger pump.

Keywords: oil pump power plant, the axial plunger pump manufacturers, variable plunger pump manufacturers

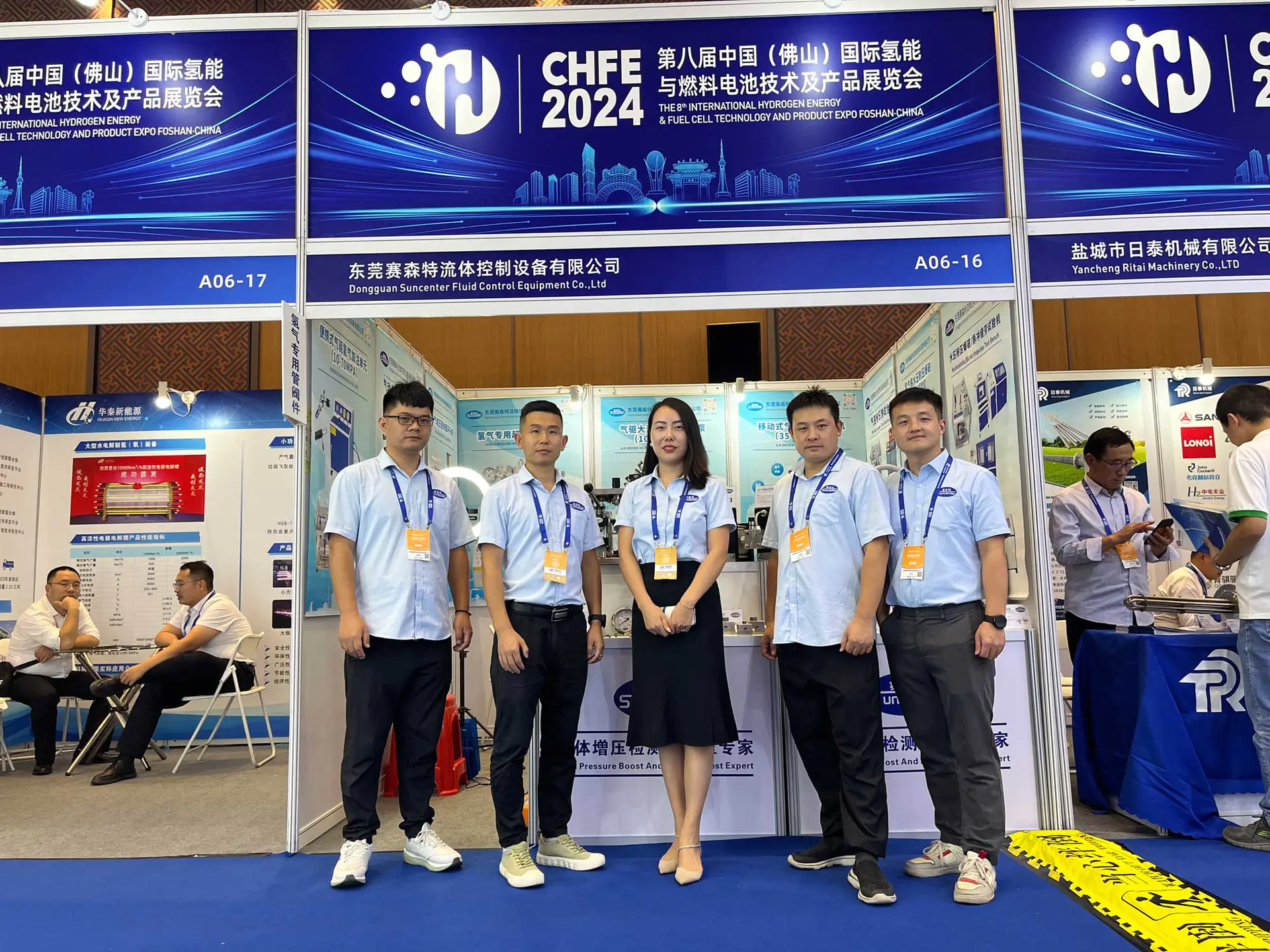

Dongguan Suncenter Fluid Control Equipment Co., Ltd have now decided to extend our company in other countries.

Boasting good reputation in the industry, Dongguan Suncenter Fluid Control Equipment Co., Ltd is the leading gas booster supplier, offering high quality and gas booster services for homes and enterprised all over the world. More info on Suncenter Fluid Control Equipment.

Along the way, Dongguan Suncenter Fluid Control Equipment Co., Ltd will face a wide range of challenges. The most successful will show our resolve by working through the challenges and finding ways to improve and grow.

The best way of hydraulic pressure pump is to get a hydraulic pressure pump gas booster.

Dongguan Suncenter Fluid Control Equipment Co., Ltd have now decided to extend our company in other countries.

Boasting good reputation in the industry, Dongguan Suncenter Fluid Control Equipment Co., Ltd is the leading gas booster supplier, offering high quality and gas booster services for homes and enterprised all over the world. More info on Suncenter Fluid Control Equipment.

Along the way, Dongguan Suncenter Fluid Control Equipment Co., Ltd will face a wide range of challenges. The most successful will show our resolve by working through the challenges and finding ways to improve and grow.

The best way of hydraulic pressure pump is to get a hydraulic pressure pump gas booster.

Custom message