The axial plunger pump maintenance note guide

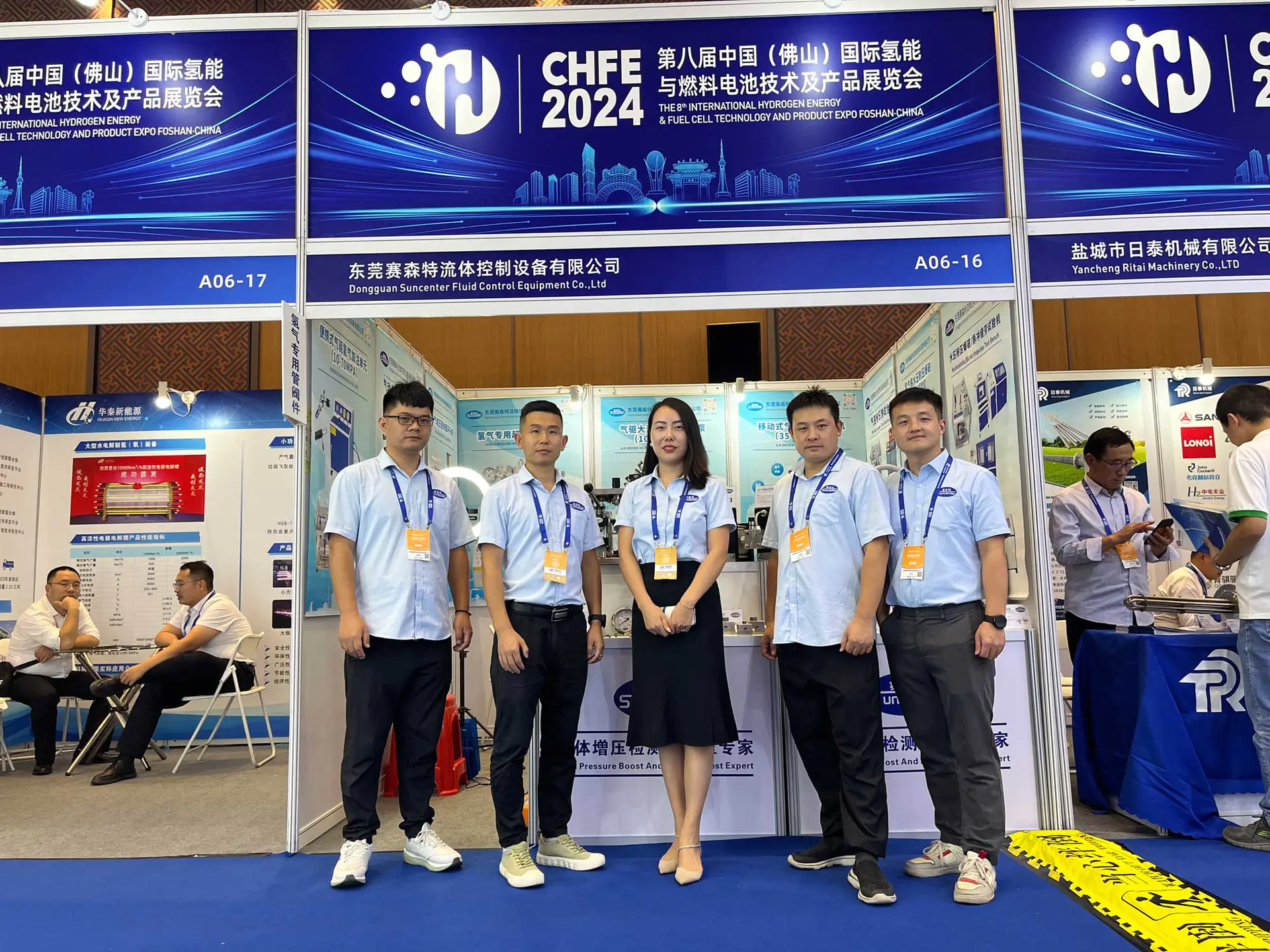

by:Suncenter

2020-08-13

1.

About protection of axial piston pump manufacturer, don't know if you have this experience.

Today, let's give our sharing our experience, expect to understand those requirements to protect the axial plunger pump is a little help.

Axial piston gas booster pump using full length, and the protection of the normal maintenance, quality and quantity of hydraulic oil, the oil cleanliness and so on.

Prevent particles in the oil formation of plunger pump friction pair wear, etc. , and extending life spans of the axial piston pump effective way.

In maintenance replacement parts should as far as possible using the original factory production parts, these parts are sometimes more expensive than other generic parts quotation, but the quality is better and safe sex, if purchasing price cheaper generic parts, saving the cost seems to be in the short term, but it brings hidden trouble, also may use of axial piston pump to form large damage.

2.

Choose to fill oil axial piston pump, the pump use after 3000 h, operators need to daily axial plunger pump to check 1 -

2 times, to check the hydraulic pump operation activity is normal.

When the hydraulic cylinder speed drop or stuffy car is found, it should be to view the disintegration of fill oil gas booster pump, check the edge of the impeller have scratches, internal gear pump gap is too big.

Of imbibition oil type plunger pump, hydraulic oil within the tank oil shall not be lower than the lower limit, insist on satiety quantity of hydraulic oil.

The higher the purity of the hydraulic oil, the longer the use of hydraulic pump life.

3.

Axial piston pump manufacturer is bearing the important parts, if the bearing clearance, do not guarantee the hydraulic pump internal three normal gap of friction pair, together will also damage the friction pair hydrostatic bearing oil film thickness, decline in the use of plunger pump bearing life spans.

According to the hydraulic pump factory supply material, bearing the uniform use of stature for 10000 h, beyond this value needs to replace new mouth.

Bearing is removed, no inspection equipment is unable to check out the bearing clearance, can only choose visual, such as found scratches or discoloration, roller appearance is replaced.

4.

In the replacement bearing, should pay attention to the English letters and type of the original bearing, piston pump bearing mostly choose the load bearing capacity, purchasing the original factory, original standard goods, if replace another brand, should be for those with experience of bearing look-up table exchange, intent is to stick to the bearing level of accuracy and load capacity.

Axial piston pump can also be used inverter power savings, axial plunger pump in the process of practical production, the general operation is under the condition of pressure or flow to regulate operation condition.

When practice pressure is greater than the demand, is through the relief valve to regulate, make the operation pressure stick to secure the overflow valve casting more than some.

All cylinders and motor has always been in a repetitive movements, power consumption is constant.

5.

Valve plate with plane flow and spherical flow in two ways.

Spherical flow friction pair, lighter scratches on surface of the cylinder block with flow, after grinding technique modification;

Cylinder valve surface groove is deep, should choose 'appearance engineering technique after filled grooves, and then to grinding, no grinding, blindly, in case the copper layer thinning or leak out steel base.

Was elected with the overflow to regulate pressure and flow rate, there are some allowance for the overflow back to the original system, and then form a plunger pump is useless power, the efficiency is low, if use after gen jie energy-saving frequency converter, overflow valve can close it, after energy-saving inverter itself actively adjust the operating pressure, adhere to the operation pressure of safe, active tracking devices of pressure.

Realizes the initiative control and save energy consumption.

Ways big advantages is to drop the axial plunger pump operation energy consumption and save electricity effect can reach more than 30%.

Keywords: axial plunger pump manufacturers, axial piston pump manufacturer suppliers, axial plunger pump manufacturers

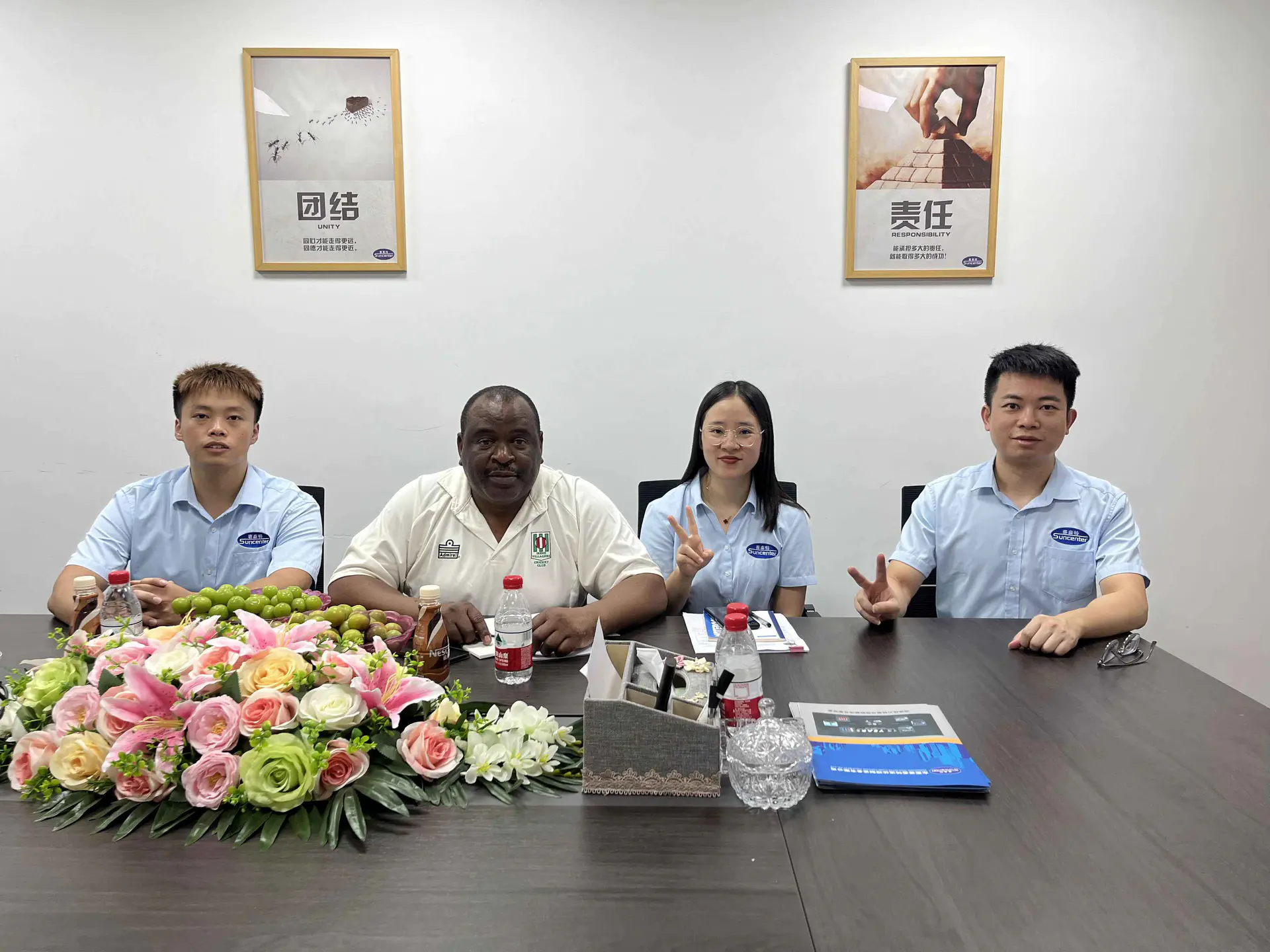

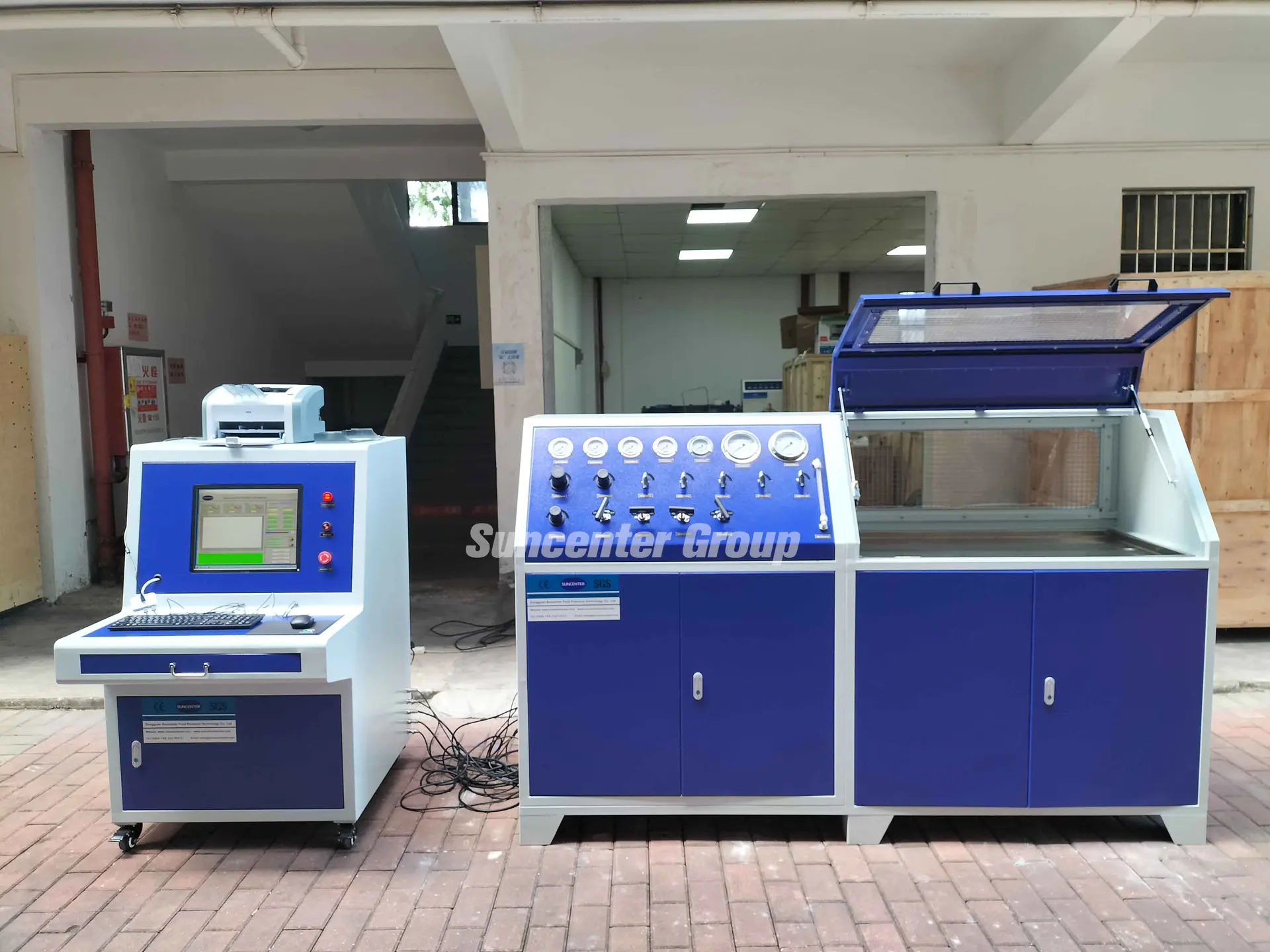

Dongguan Suncenter Fluid Control Equipment Co., Ltd is one of the most-trusted manufacturing suppliers to the domestic markets.

The best way to confront your hydraulic pressure pump problem is to search for a high quality offered by Dongguan Suncenter Fluid Control Equipment Co., Ltd at Suncenter Fluid Control Equipment. Take a look!

Dongguan Suncenter Fluid Control Equipment Co., Ltd harnesses science and technology to create products that support safer and healthier living and that enhance the overall quality of life.

Dongguan Suncenter Fluid Control Equipment Co., Ltd is one of the most-trusted manufacturing suppliers to the domestic markets.

The best way to confront your hydraulic pressure pump problem is to search for a high quality offered by Dongguan Suncenter Fluid Control Equipment Co., Ltd at Suncenter Fluid Control Equipment. Take a look!

Dongguan Suncenter Fluid Control Equipment Co., Ltd harnesses science and technology to create products that support safer and healthier living and that enhance the overall quality of life.

Custom message